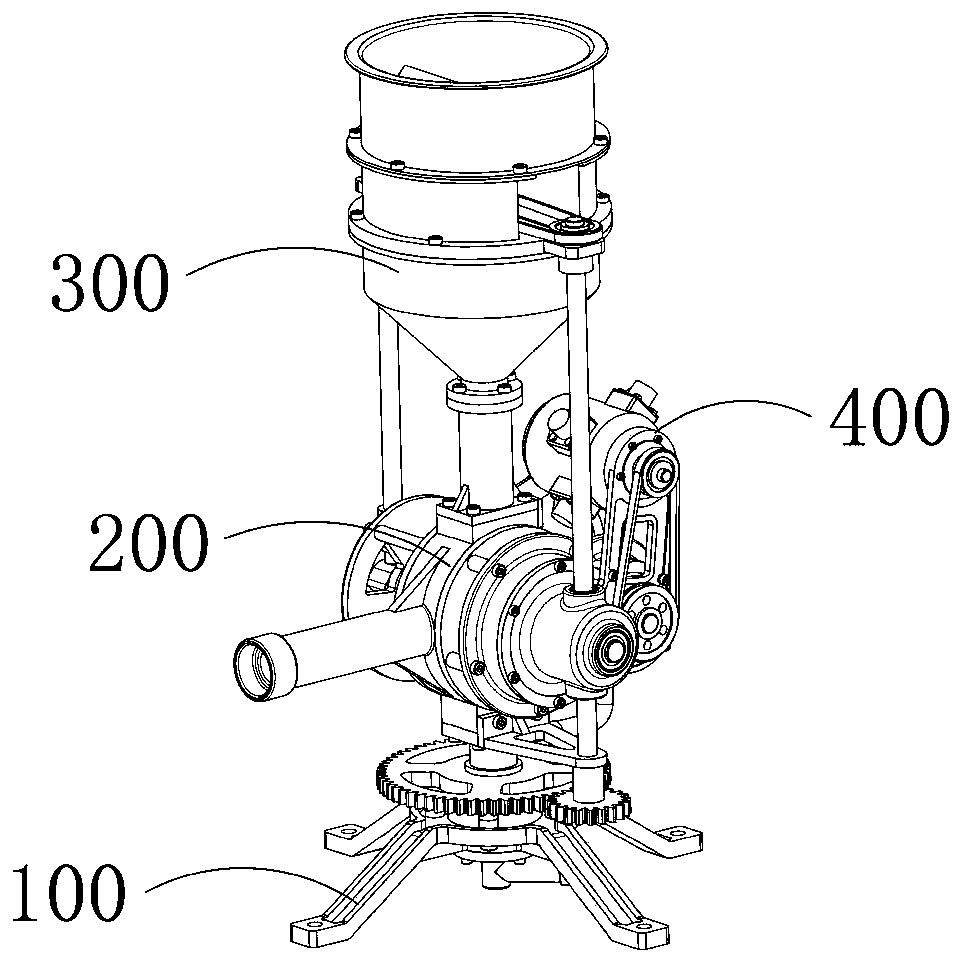

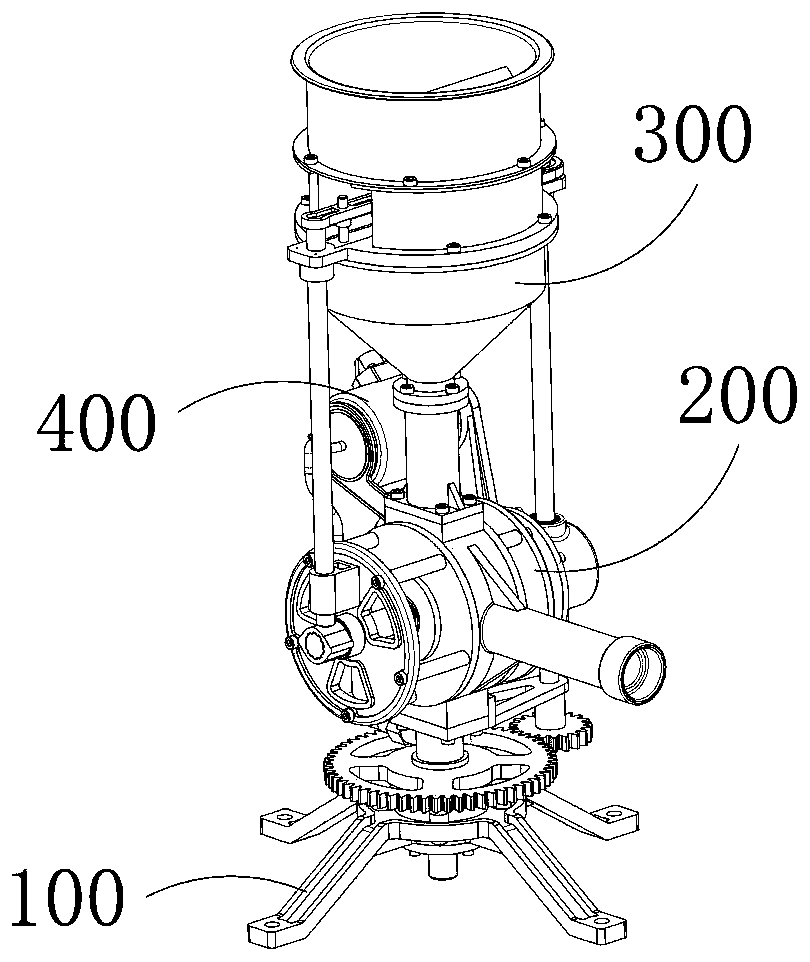

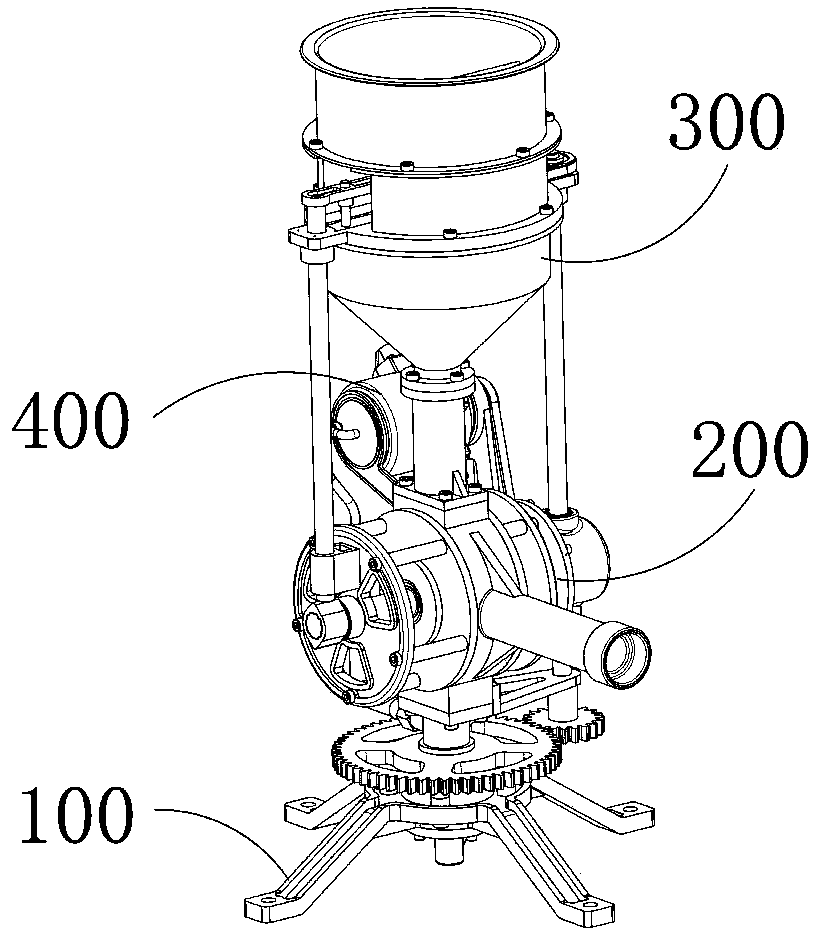

Rotary-bin type remote pneumatic feed-dispersing equipment

A technology of feed and equipment, which is applied in the field of livestock breeding, can solve the problems of high labor intensity of breeders and low efficiency of artificial feed feeding, and achieve the effect of wide feeding range, reduced labor intensity, and uniform feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0066] The advantage of feeding the feed of the present invention is that the throwing mechanism throws the feed outward at a constant rate, and at the same time, the rotating member is still the throwing mechanism rotating at a constant speed, so that the feed is evenly distributed around the feeding equipment, compared with traditional manual throwing. Feeding mode, the feeding range of this feeding equipment is wider and the feeding is more uniform. At the same time, it can effectively avoid unnecessary damage to livestock due to looting of feed. Compressed gas can be provided by a gas compressor during the entire feed throwing and feeding process. The advanced equipment is the driving source, and the breeder only needs to pour the feed into the feeding funnel, and the rest of the feeding process does not require manual operation, which greatly reduces the labor intensity.

[0067] Rotary bin type pneumatic remote feed spreading equipment, including a mounting frame body 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com