A weighing device, conveying device and method for steel rolling production

A weighing device and conveying line technology, which is applied in the field of conveying devices and weighing devices for rolling steel production, can solve the problems of increased production line area, affecting rolling quality, and prolonging billet time, so as to reduce transportation time and equipment , the effect of reducing the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

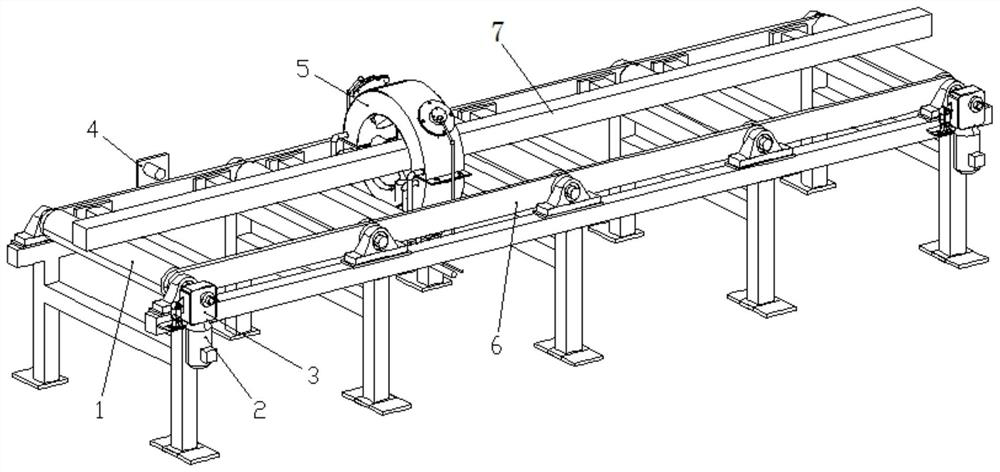

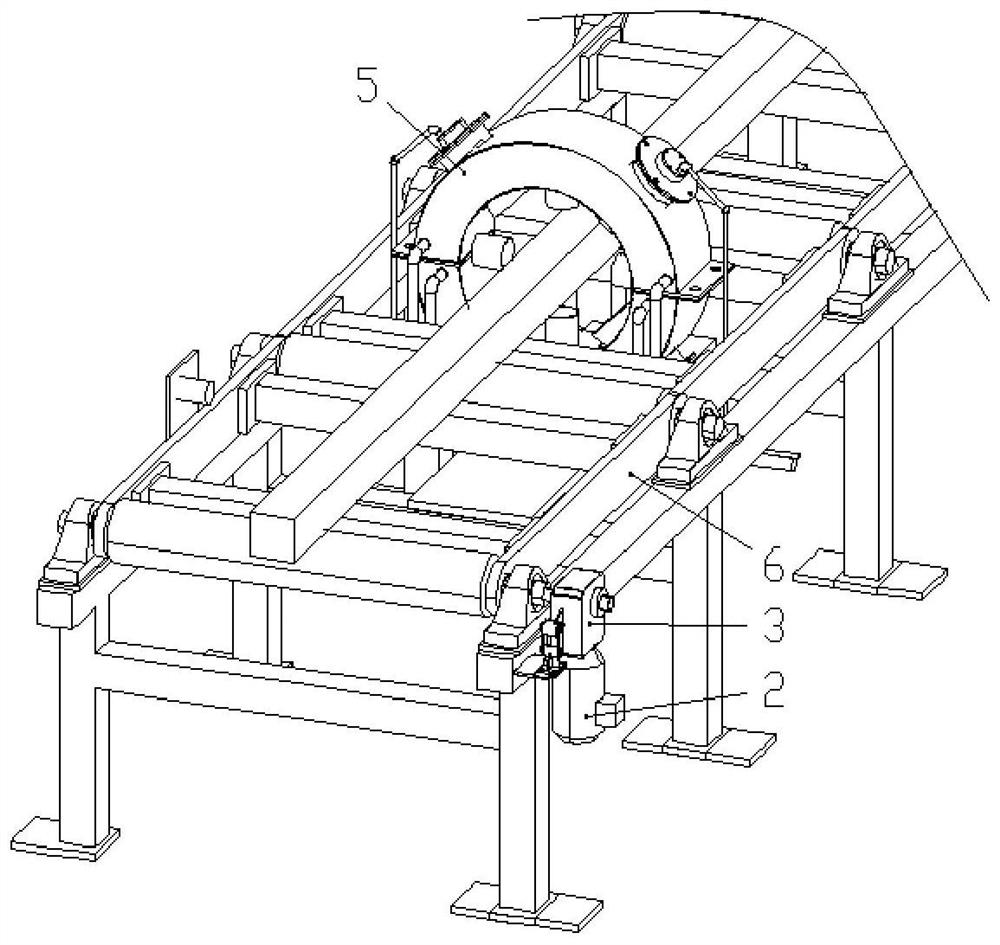

[0034] Such as Figure 1-2 As shown, this embodiment provides a weighing device for rolling steel production, including a profile scanner 5 arranged in the middle of the roller conveyor line 6, a metal detector 4 arranged on one side of the roller conveyor line 6, and a drive motor 2 A code wheel 3 coaxially arranged with the middle output shaft.

[0035] In some embodiments, the roller conveyor line 6 has a set forward direction, and the test piece 7 should reach the position of the profile scanner 5 in the roller conveyor line 6, and then reach the position of the metal detector 4, and the profile scanner The distance between 5 and the metal detector 4 should be smaller than the minimum distance of the DUT 7 .

[0036] The profile scanner 5 can allow the test piece 7 to pass and scan the cross-sectional shape of the test piece 7; the metal detector 4 can detect whether the test piece 7 arrives at the detection position of the metal detector 4; the code disc 3 can detect th...

Embodiment 2

[0046] Such as Figure 1-2 As shown, this embodiment provides a conveying device for rolling steel production, which utilizes the weighing device for rolling steel production, including a roller conveyor line 6, and the contour scanner is installed in the middle of the roller conveyor line 6 5. The metal detector 4 is provided on one side of the roller conveyor line 6, the drive roller 1 and the drive motor 2 are arranged coaxially in the roller conveyor line 6, and the output shaft of the drive motor 2 is connected to the code disc 3 Fixed connection.

Embodiment 3

[0048] This embodiment provides a weighing method for steel rolling production, which utilizes a conveying device for steel rolling production, and includes the following steps:

[0049] Place the test piece 7 with a regular shape on the upper part of the roller conveying line 6 so that the test piece 7 is transported along the conveying direction of the roller conveying line 6 .

[0050] After the front end of the DUT 7 reaches the position of the metal detector 4, the code disc 3 starts to record the angle information, and when the rear end of the DUT 7 moves away from the position of the metal detector 4, the code disc 3 stops recording the angle information, The angle information recorded by the device code disc 3 and the radius of the driving roller 1 in the roller conveyor line 6 are used to obtain the length value of the test piece 7 .

[0051] When the front end of the test piece 7 reaches the position of the metal detector 4, the weighing device controls the imaging s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com