Automatic bag removing device for material

A kind of material and automatic technology, applied in the direction of packaging, transportation and packaging, unsealing of objects, etc., can solve the problems of damage, increase of production cost, material leakage, etc., achieve the effect of reducing production cost, improving production efficiency, and solving material leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The automatic material bag unpacking device of the present invention will be further described below in conjunction with the embodiments and accompanying drawings.

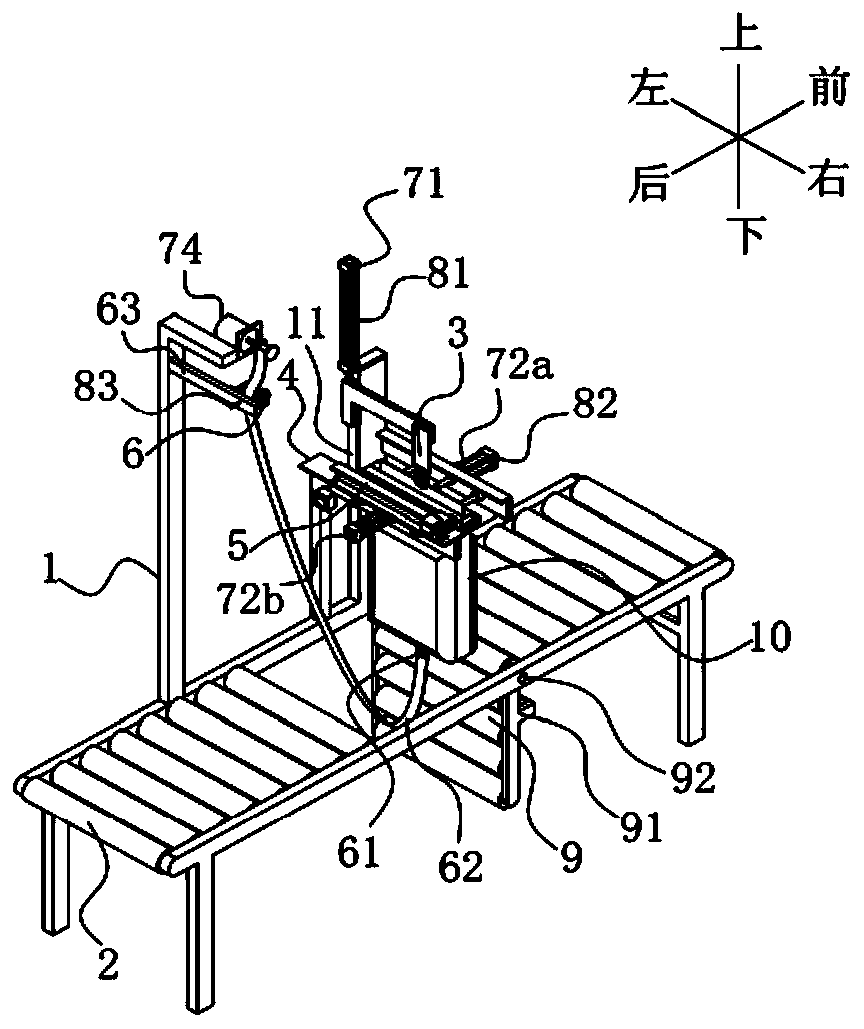

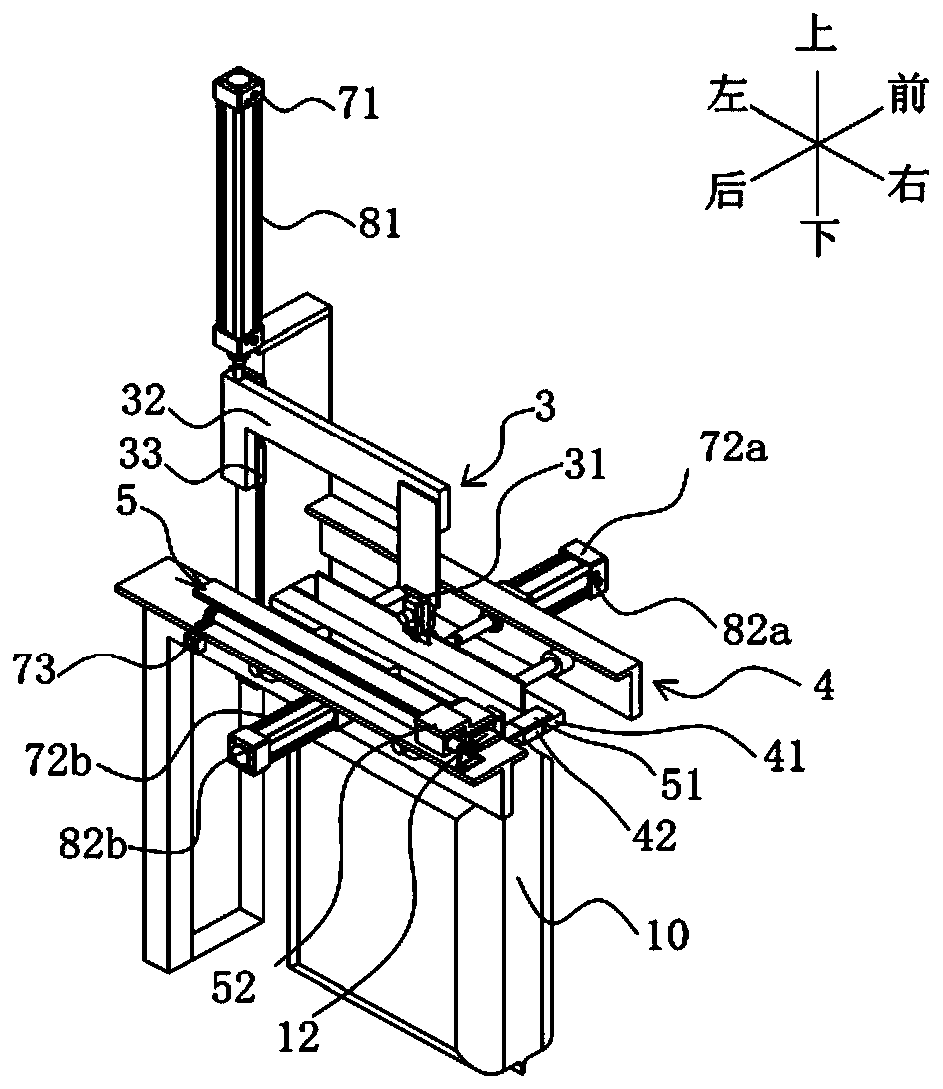

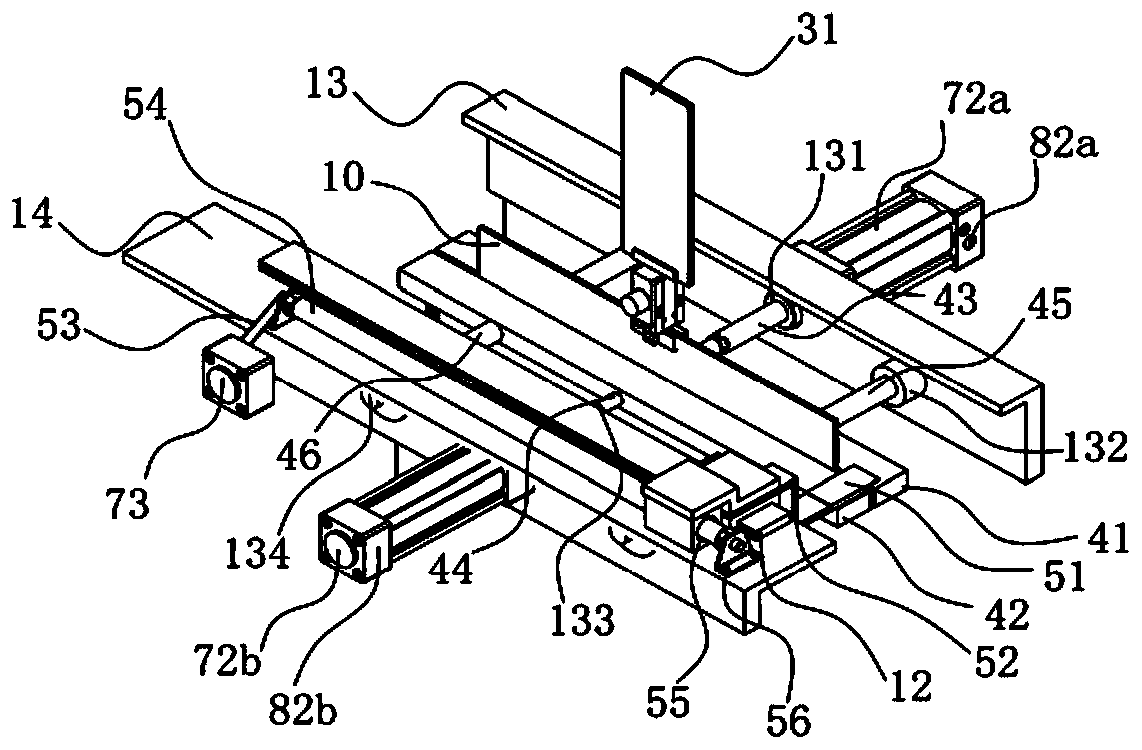

[0020] Such as figure 1 As shown, the material automatic bag unpacking device of the present invention comprises a support 1; a conveying part 2 is supported by the support 1, and the conveying part 2 is provided with a rolling part and a power supply for conveying materials in the inner packaging bag and the outer packaging bag 10. Unit, in this embodiment, the rolling member can be a device such as a roller, a belt, a gear, etc., which can carry out material transportation, such as a roller; the first clamping part 3 is located above the conveying part 2, and is slidably supported by the bracket 1 for clamping Holding the outer packaging bag 10, the outer packaging bag 10 is moved up and down, with a first position located at the initial position of the first clamping part 3 and a second position at the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com