Production process of ultrathin hyperboloid aluminum honeycomb stone material large plate and application thereof

A production process and hyperboloid technology, which is applied to building components, covering/lining, walls, etc., can solve the problems of fragility and hyperboloid stone slabs cannot be reinforced, and achieve weight and material cost reduction, installation cost reduction, risky effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

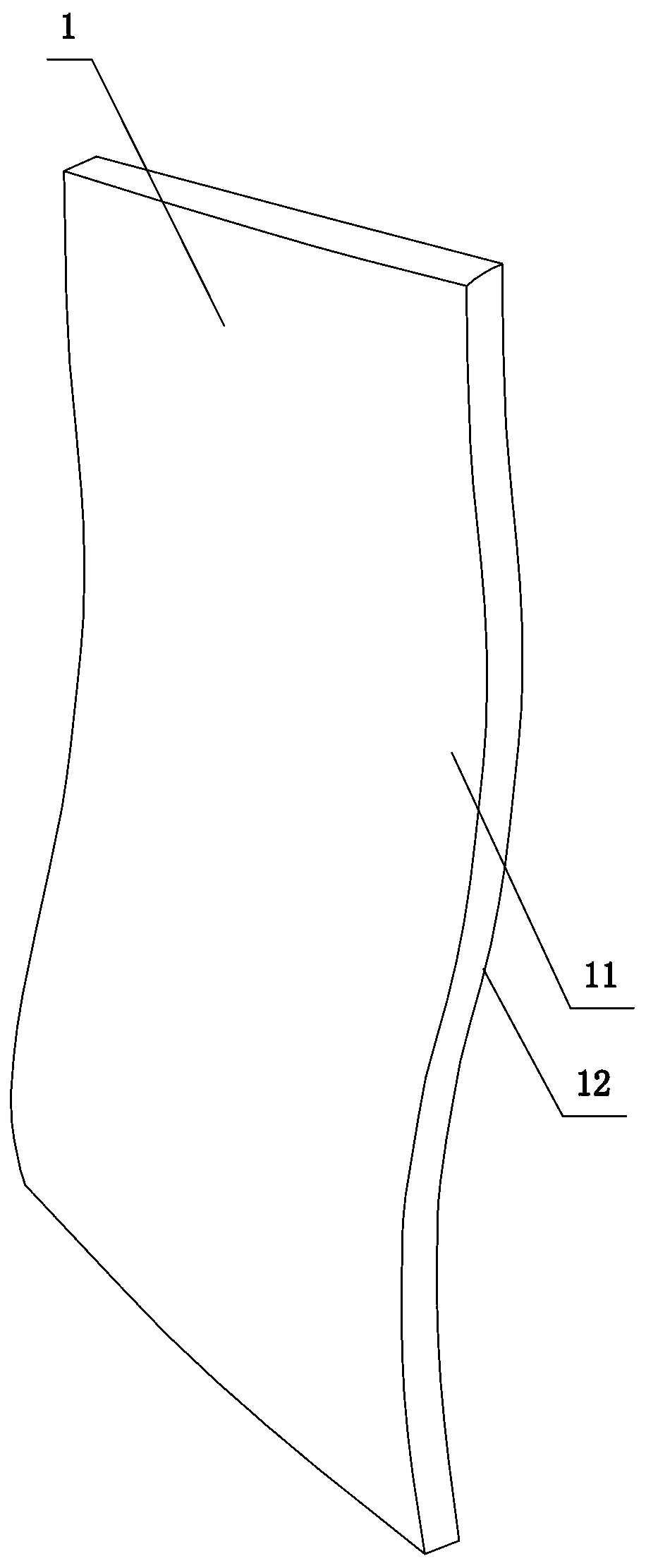

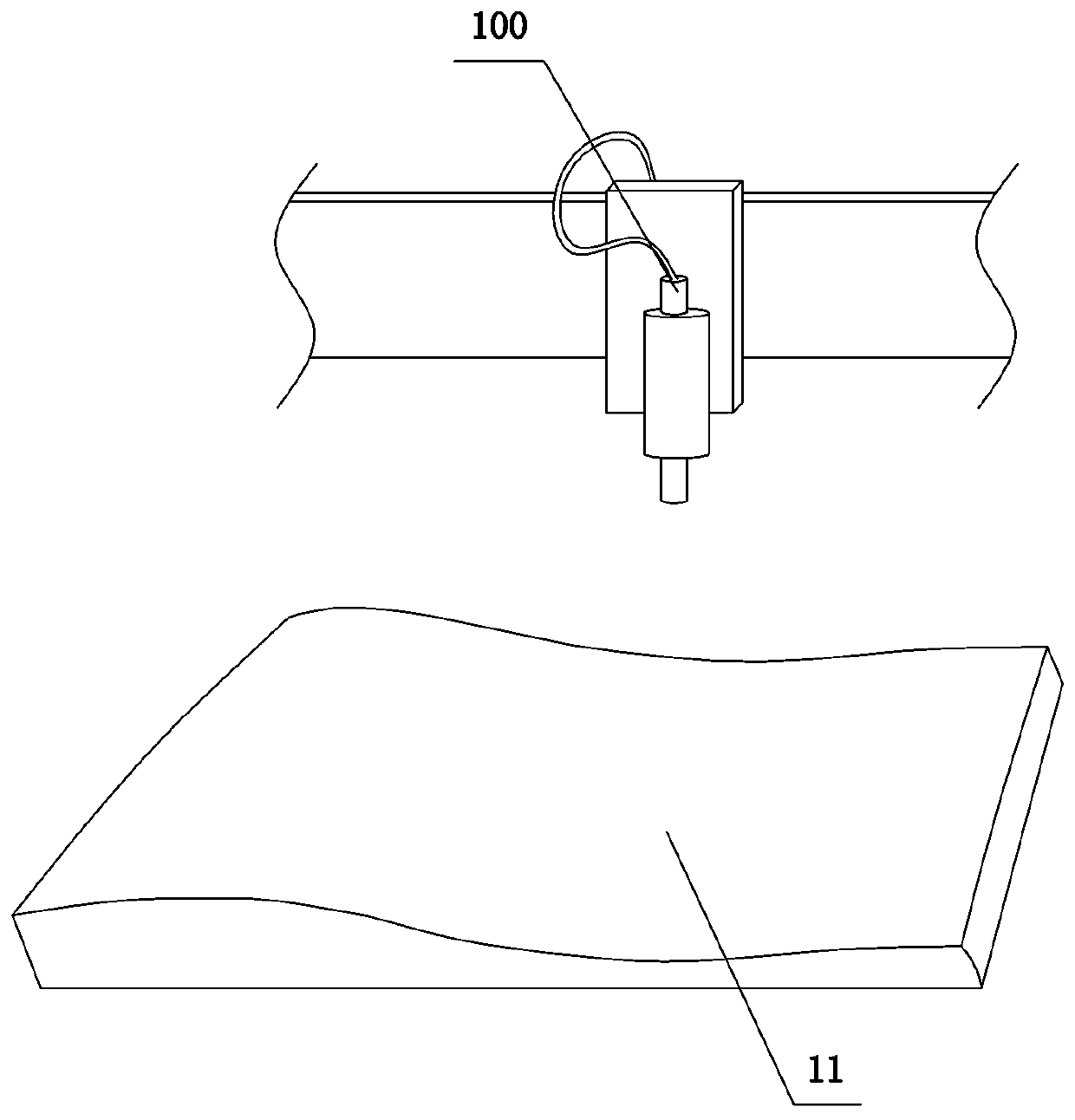

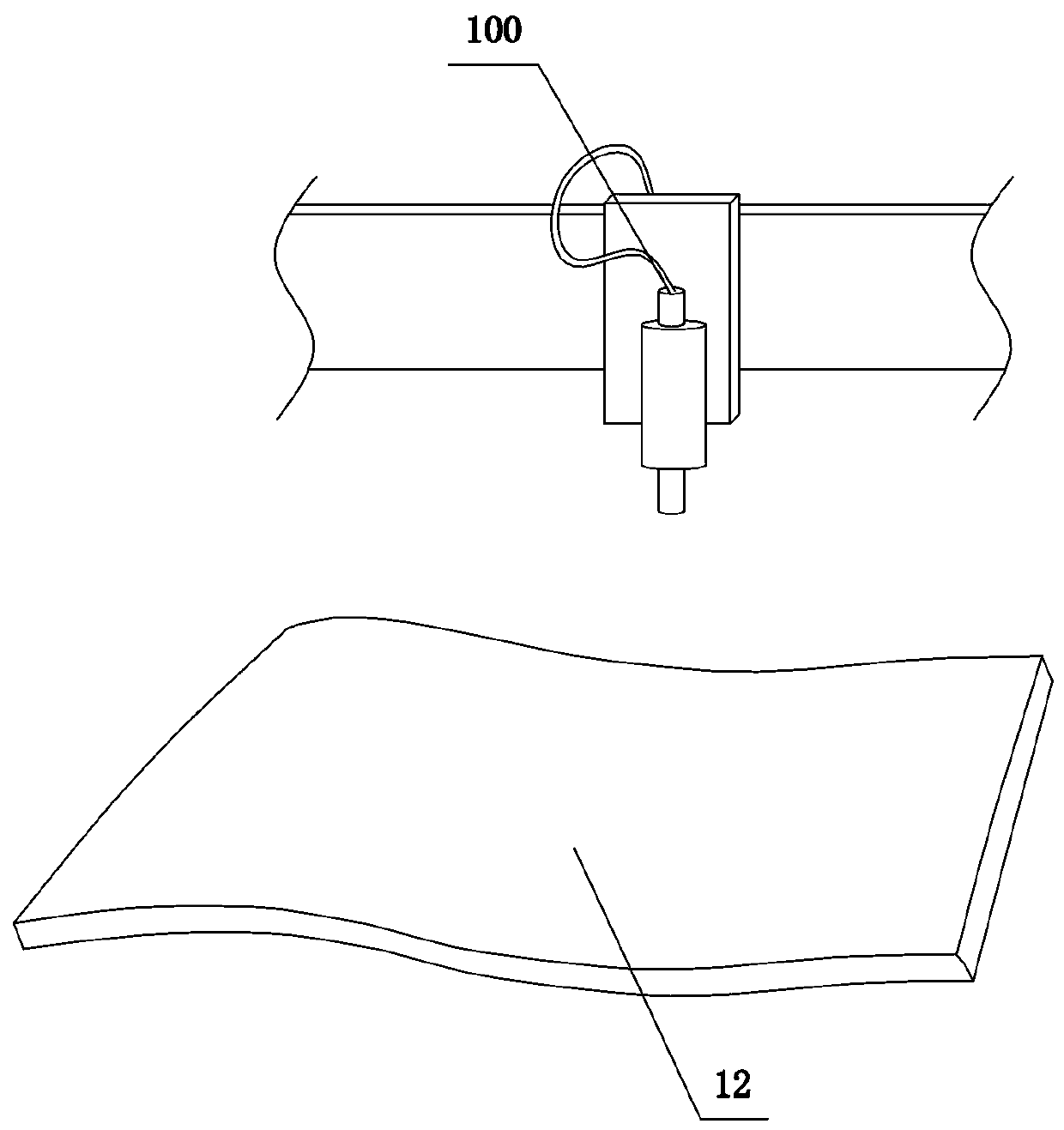

[0042] refer to figure 1 , figure 2 , image 3 , Figure 4 . A production process of an ultra-thin hyperboloid aluminum honeycomb stone slab, comprising the following steps:

[0043] 1. Take a stone panel 1, and carve a hyperboloid on the front side 11 of the stone panel 1 according to the required splicing design. In order to reduce the weight, the thickness of the stone panel obtained after carving is less than 2 cm;

[0044] 2. Compositely connect the reinforcement layer 2 on the reverse side 12 of the stone panel 1. The reinforcement layer 2 includes a first layer of aluminum skin 21, a plurality of honeycomb core materials 22, and a second layer of aluminum skin 23.

[0045] In this embodiment, specifically include the following steps:

[0046] a) Take a stone panel 1, and use a three-axis engraving machine 100 to carve a hyperboloid on the front side 11 of the stone panel 1 according to the required splicing design;

[0047] b) Carve a hyperboloid on the reverse sid...

Embodiment 2

[0060] refer to Figure 9 , Figure 10 . A production process of an ultra-thin hyperboloid aluminum honeycomb stone slab, comprising the following steps:

[0061] 1. Carve a hyperboloid on the front side 31 of the stone panel 3 according to the required splicing design. In order to reduce the weight, the thickness of the stone panel obtained after carving is less than 2 cm; wherein, the hyperboloid carved on the stone panel 3 The method can be: use a 3-axis stone engraving machine to carve a hyperboloid according to the required splicing design;

[0062] 2. The reverse side 32 of the stone panel 3 is a plane, and the reinforcement layer 4 is compositely connected to the reverse side 32 of the stone panel 3 , and the reinforcement layer 4 is an aluminum honeycomb panel 4 .

[0063] refer to Figure 9 , Figure 10 . A stone slab produced by the above-mentioned production process of an ultra-thin hyperboloid aluminum honeycomb stone slab, comprising a stone panel 3 and an a...

Embodiment 3

[0067] refer to Figure 11 , Figure 12 . A production process of an ultra-thin hyperboloid aluminum honeycomb stone slab, comprising the following steps:

[0068] 1. Carve a hyperboloid on the front side 51 of the stone panel 5 according to the required splicing design. In order to reduce the weight, the thickness of the stone panel obtained after carving is less than 2 cm; wherein, the hyperboloid carved on the stone panel 5 The best method is: use a 3-axis stone engraving machine to carve a hyperboloid according to the required splicing design;

[0069] 2. The reverse side 52 of the stone panel is a curved surface. Take an aluminum honeycomb panel 6, and make the front side 61 of the aluminum honeycomb panel 6 into a radian corresponding to the curved surface by means of a mold or by hand beating and customizing. The front side 61 of the aluminum honeycomb panel is composited to the back side 52 of the stone panel.

[0070] refer to Figure 11 , Figure 12 . A stone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com