Hole sealing door device and transportation method

A technology for sealing doors and gaskets, which is applied to sealing devices, door leaves, service doors, etc. It can solve the problems that it is difficult to ensure the pressure tightness and safety of the sealing door, the quality of the sealing door is large, and the construction period is long. Open the hole sealing door and the transportation passage door, the effect of high safety and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] The hole sealing door device in this embodiment includes a hole sealing door, a first locking mechanism and a first sealing mechanism.

[0087] Wherein, the area of the hole sealing door is larger than that of the hole, and the edge of the hole sealing door is in contact with the wall at the edge of the hole to close the hole.

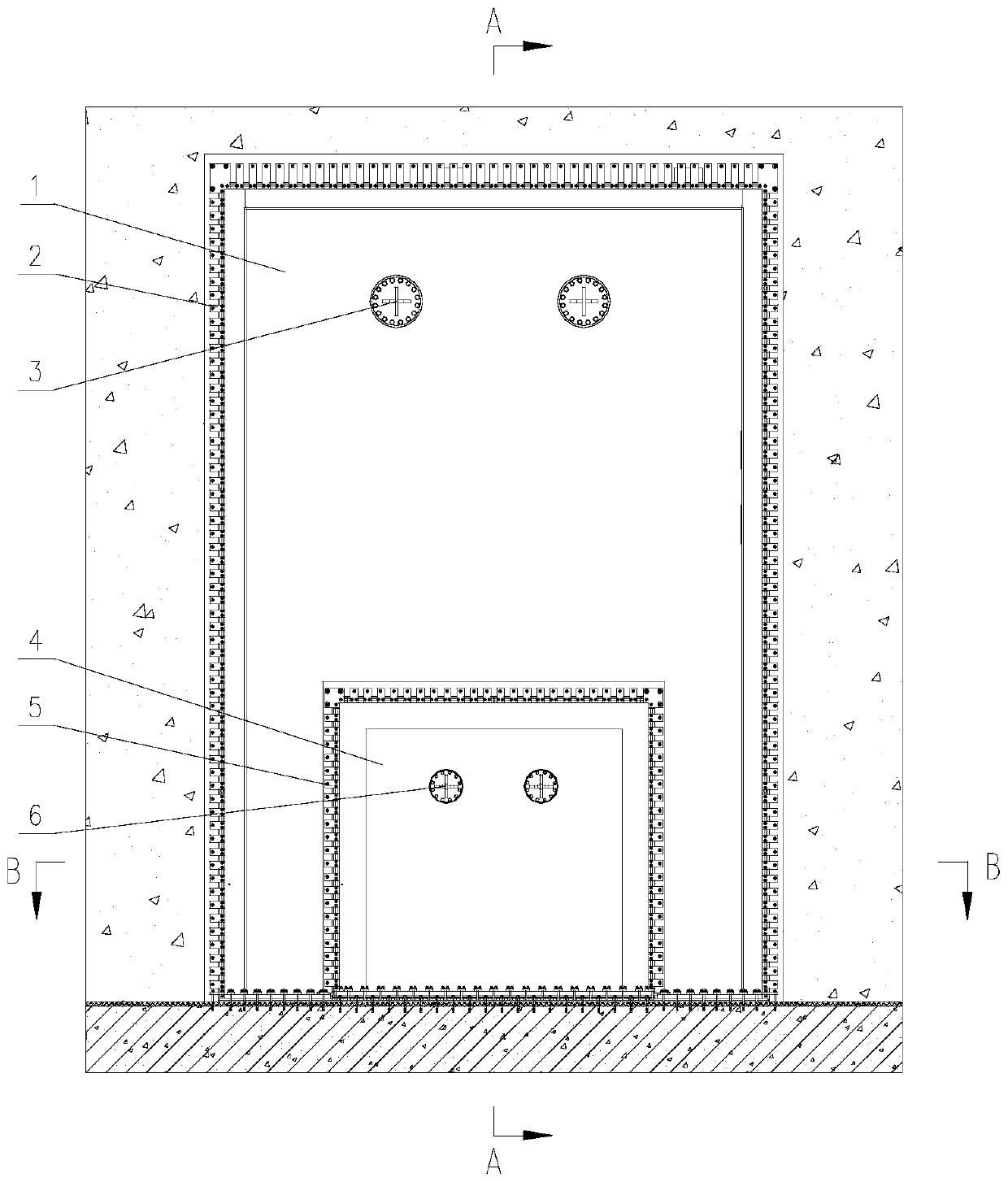

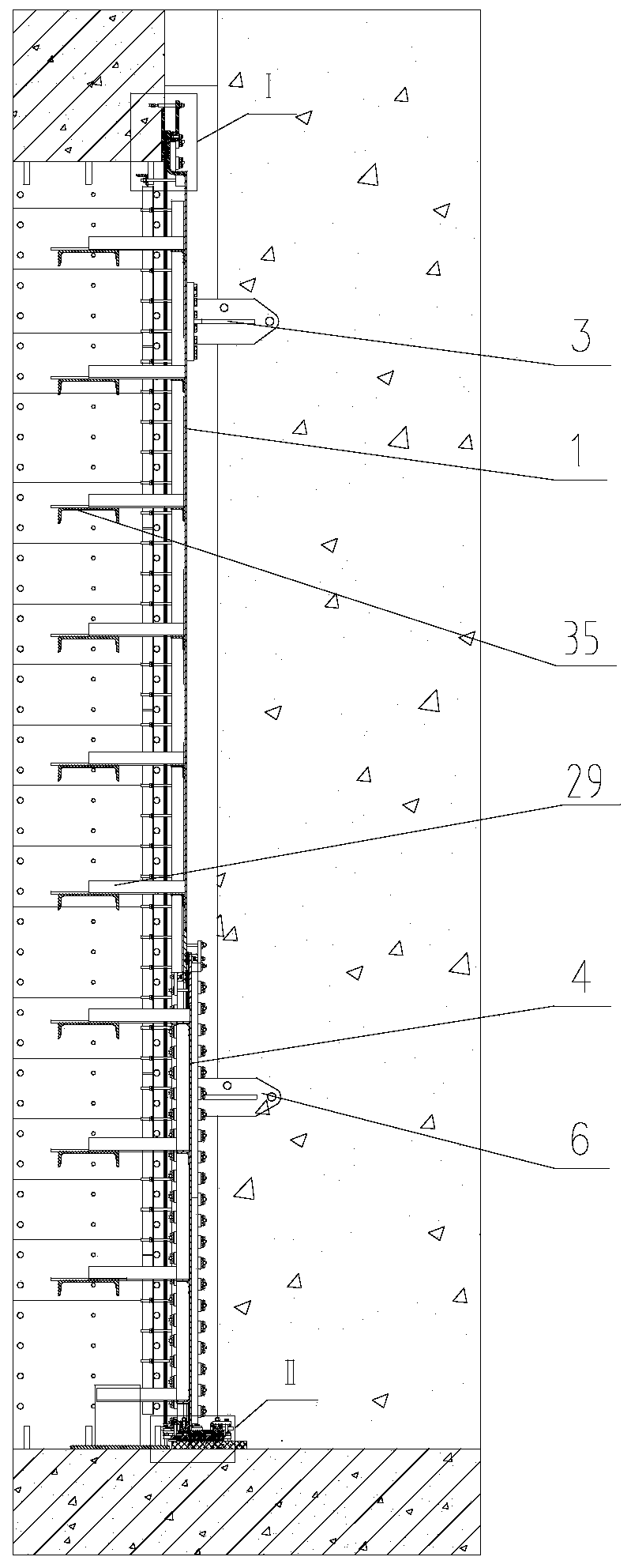

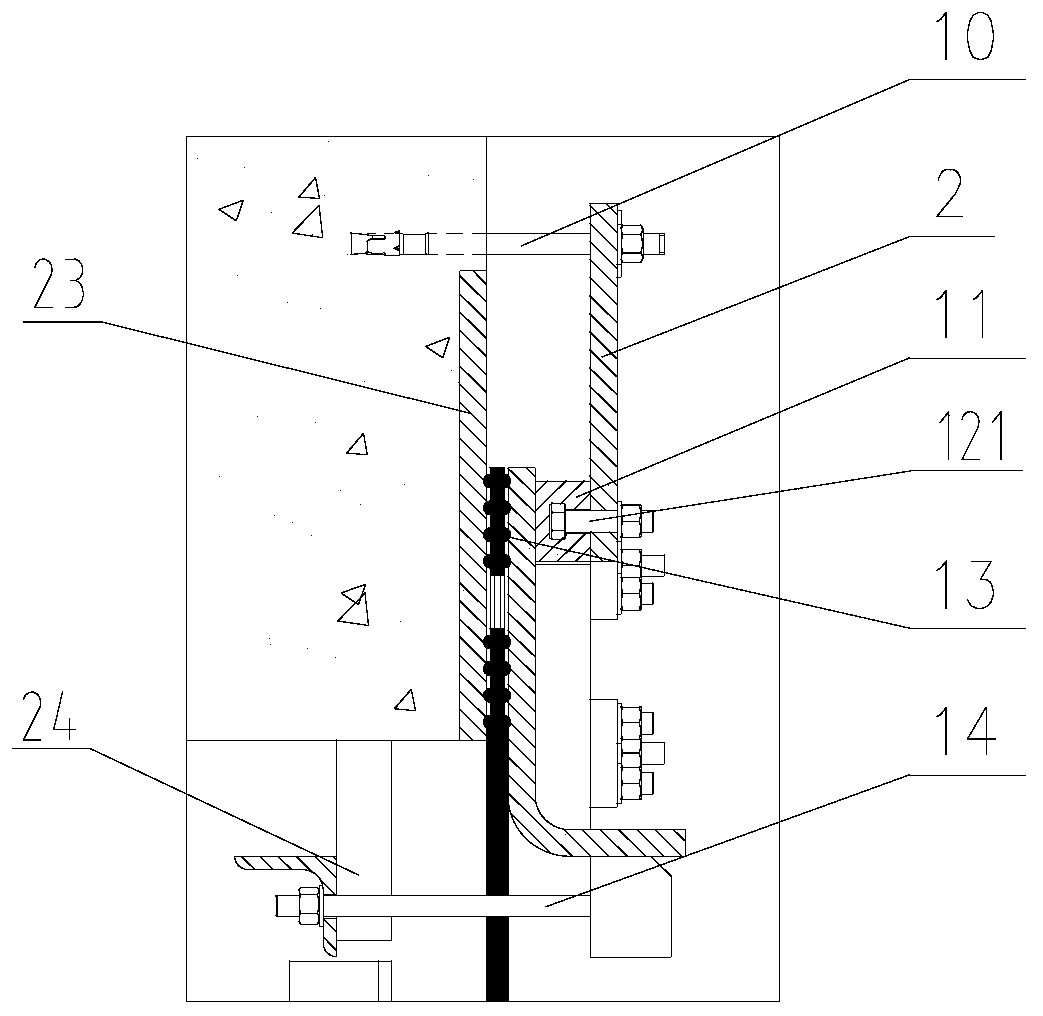

[0088] Such as figure 1 As shown, the hole sealing door includes a hole sealing door panel 1 and a hole sealing door bottom plate 25, wherein the direction of the hole sealing door panel 1 is perpendicular to the direction of the hole sealing door bottom plate 25, and the hole sealing door panel 1 is sealed with the hole. The door bottom plate 25 is fixedly connected.

[0089] The first locking mechanism includes a first front locking unit and a first rear locking unit. The first front locking unit is used to lock the hole sealing door panel 1 and the wall from the front of the hole sealing door.

[0090] Specifically, in this embodiment, t...

Embodiment 2

[0107] This embodiment provides a hole sealing door device, the structure of which is the same as that of the hole sealing door device described in Embodiment 1. The difference between the two is that in this embodiment, the hole sealing door panel 1 is provided with a transportation channel door opening , the door opening of the transportation passage door is closed by the transportation passage door.

[0108] Such as figure 1 As shown, the transportation passage door includes a transportation passage door panel 4 and a transportation passage door bottom plate 26, wherein the direction of the transportation passage door door panel 4 is perpendicular to the direction of the transportation passage door bottom plate 26, and the transportation passage door door panel 4 and the transportation passage door bottom plate 26 are perpendicular to each other. The transport channel door bottom plate 26 is fixedly connected.

[0109] Wherein, the area of the transportation passage door...

Embodiment 3

[0139] This embodiment provides a transport method for transporting large-scale equipment to the nuclear test plant, including the following steps:

[0140] S11, installing the hole sealing door device as described in embodiment 1 or embodiment 2 at the hole position of the nuclear test building;

[0141] S12, inspect the airtightness of the hole sealing door device, and then inspect the airtightness of the nuclear test plant until the inspection is qualified;

[0142] S13, remove the hole seal door from the hole, and transport the large equipment to the nuclear test plant;

[0143] S14, reinstalling the hole sealing door to the hole, and using concrete to block the hole sealing door device.

[0144] In this embodiment, the size of the large door opening of the nuclear test plant is 8.5 meters * 5.4 meters, and then the opening sealing door device as described in embodiment 1 or embodiment 2 is installed on the door opening. Wherein, in step S12, the specific operation proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com