Direct-current frequency-conversion carbon dioxide heat pump chilling and heating unit

A carbon dioxide and DC frequency conversion technology, which is applied in the direction of heating and cooling combination, refrigerator, refrigeration components, etc., can solve the problem of single application range, achieve the effect of wide application range, reduce energy consumption, and reduce compression ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to describe the technical content, structural features, achieved goals and effects of the invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

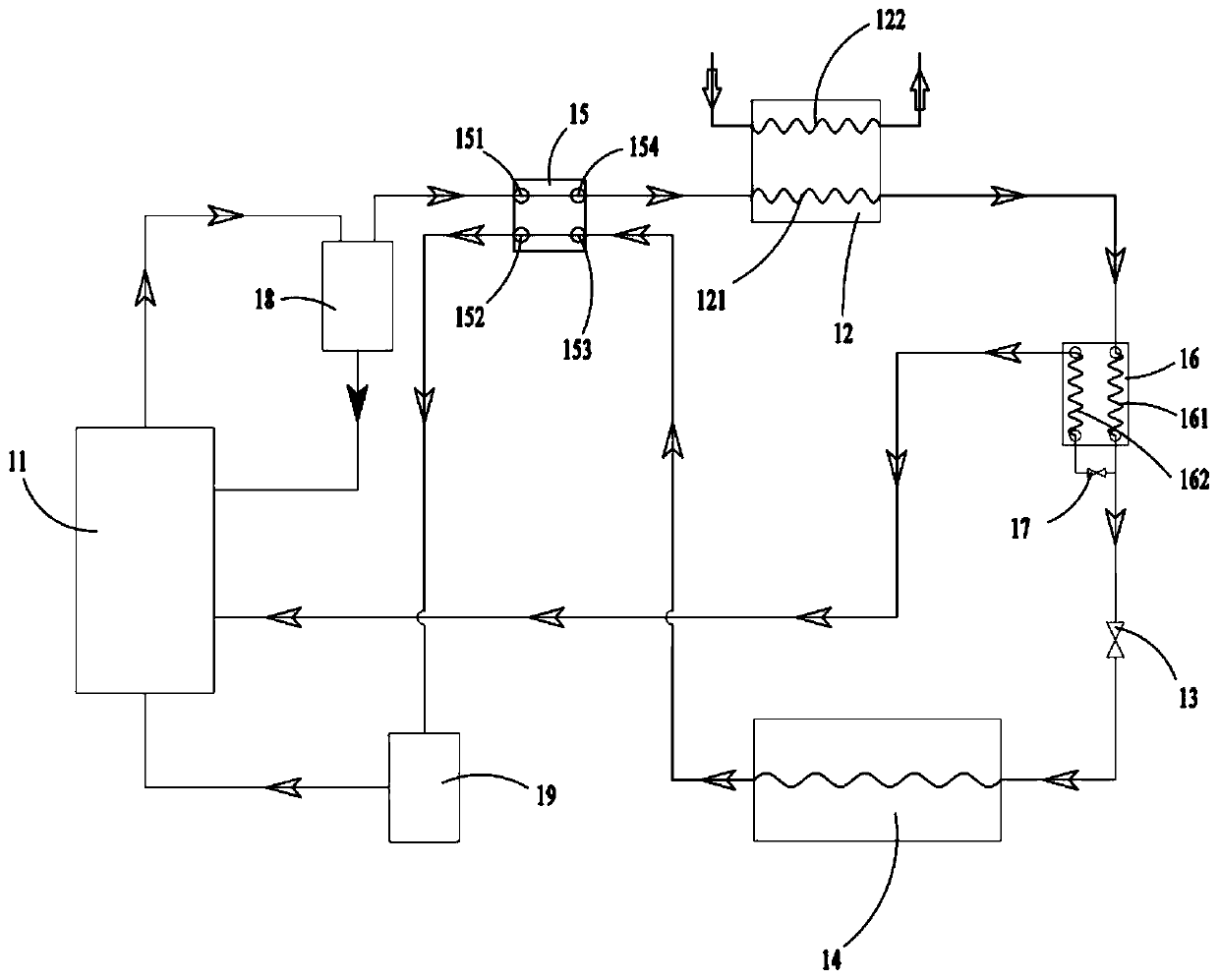

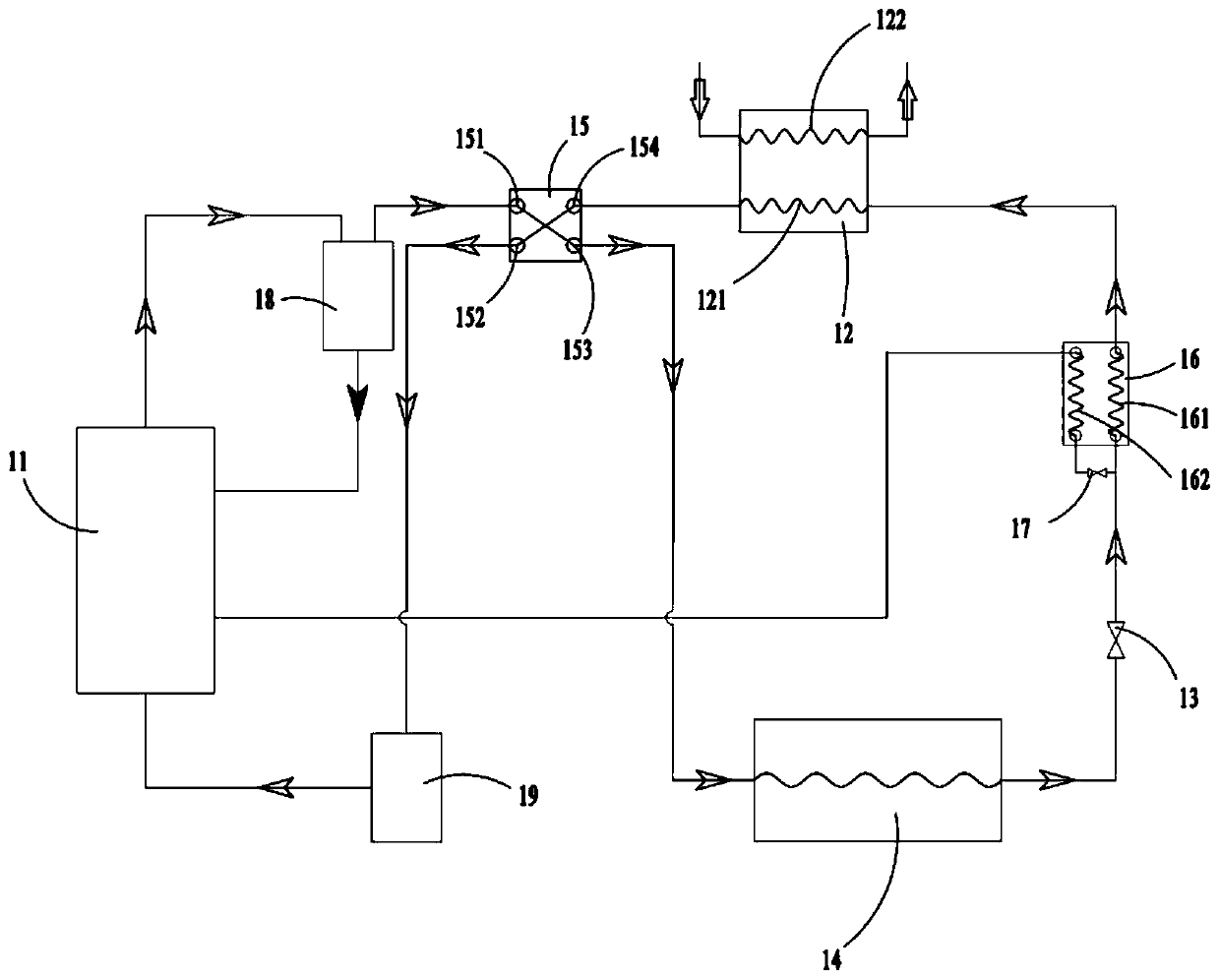

[0021] Such as Figure 1-Figure 2 As shown, the DC variable frequency carbon dioxide heat pump cooling and heating unit includes a compressor 11 , a four-way valve 15 , an air cooler 12 , a supplementary air enthalpy increasing heat exchanger 16 , a first expansion valve 13 , a second expansion valve 17 and an evaporator 14 .

[0022] Wherein, the compressor 11 is a DC inverter compressor 11 . The four-way valve 15 is disposed between the compressor 11 and the air cooler 12 , and has a first valve port 151 , a second valve port 152 , a third valve port 153 and a fourth valve port 154 . The air cooler 12 has a first heat exchange pipe 121 and a water exchange channel 122 that exchange heat with each other. The supplementary air enthalpy-increasin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com