Overpressure protection system for reactor cabin

A technology for reactor cabin and overpressure protection, which is applied to reactors, emergency protection devices, nuclear power generation, etc., can solve problems affecting the safety of reactor cabins and internal equipment, and achieve the effects of protecting safety, avoiding accidental leakage, and suppressing internal pressure rises

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] For a better understanding of the present invention, the present invention will be further described below with reference to the accompanying drawings and specific embodiments.

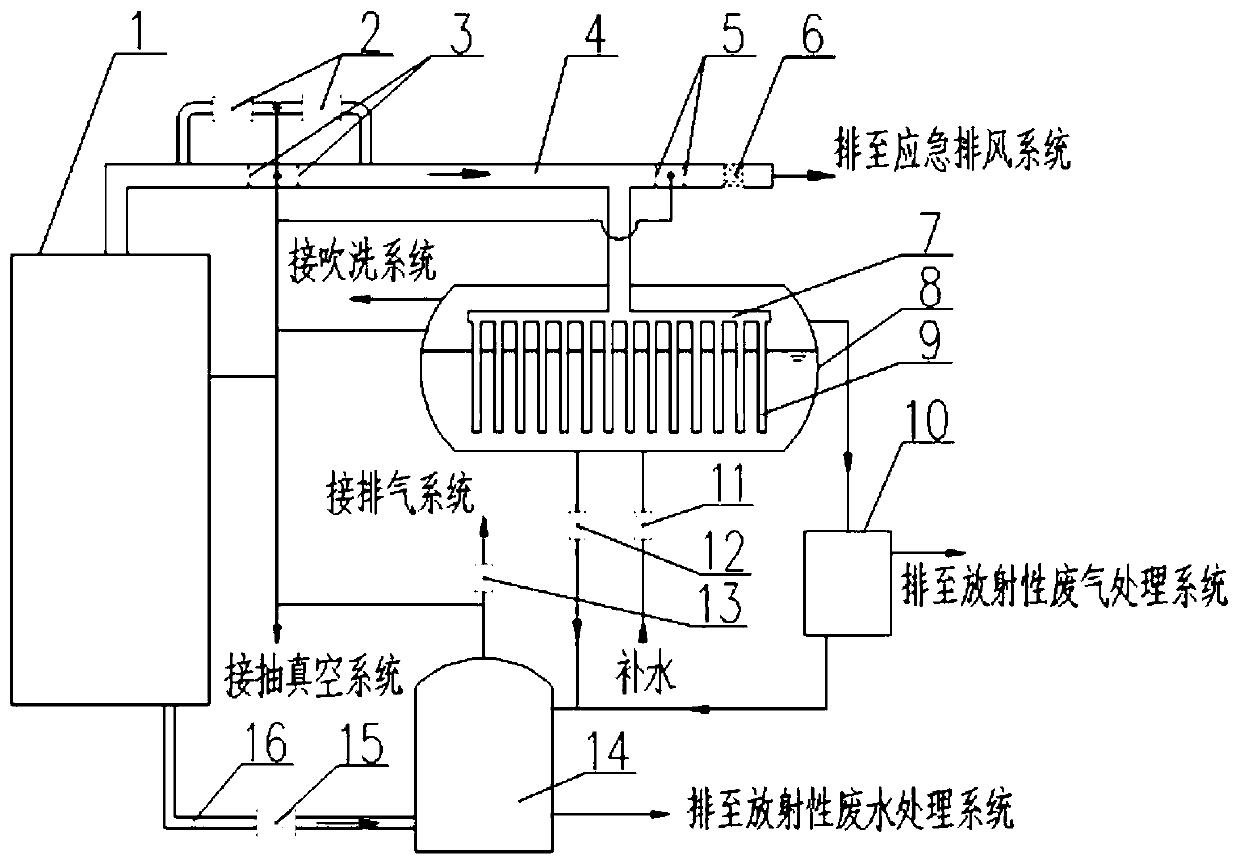

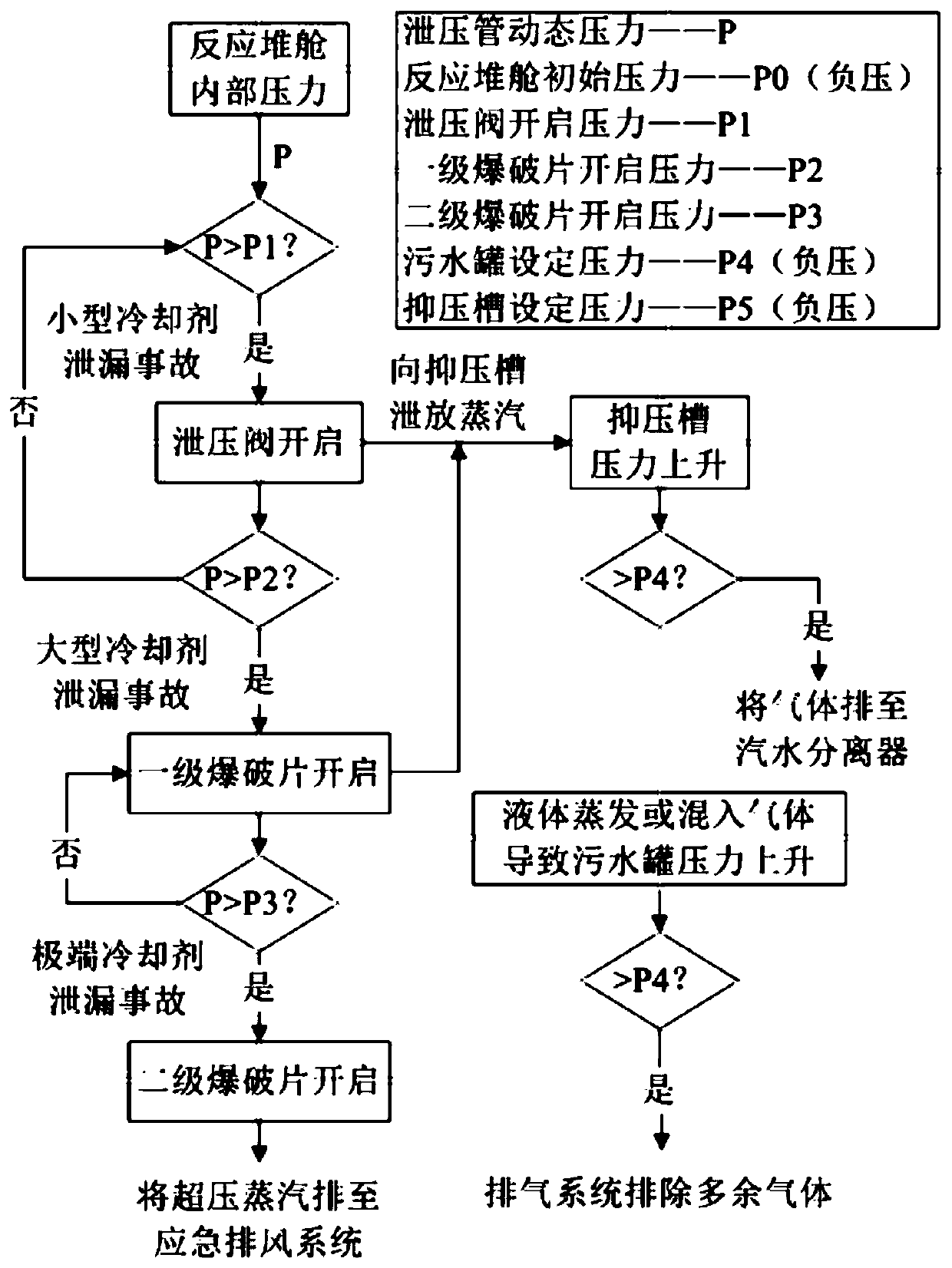

[0020] like figure 1 The overpressure protection system of a reactor compartment 1 shown includes a pressure relief pipe 4, a multi-stage pressure relief assembly, a suppression assembly and a sewage tank, and the inlet end of the pressure relief pipe 4 communicates with the interior of the reactor compartment 1; The first-level pressure relief assembly is installed in the pressure relief pipe 4 or on the bypass branch pipe of the pressure relief pipe 4; the pressure relief assembly communicates with the pressure relief pipe 4; The bottom of cabin 1 is connected, and the outlet of the sewage tank is connected with the radioactive waste water treatment system.

[0021] In this embodiment, a safety drain valve 15 is installed on the safety drain line 16; the safety drain line 16 is used to disch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com