Spraying protection process method of repaired rotor guard ring spigot

The invention relates to a technology of a rotor guard ring and a process method, which is applied in the direction of coating, a device for coating liquid on the surface, etc., which can solve the problems of inability to use protection and high temperature of the sprayed material, and achieve the effect of reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

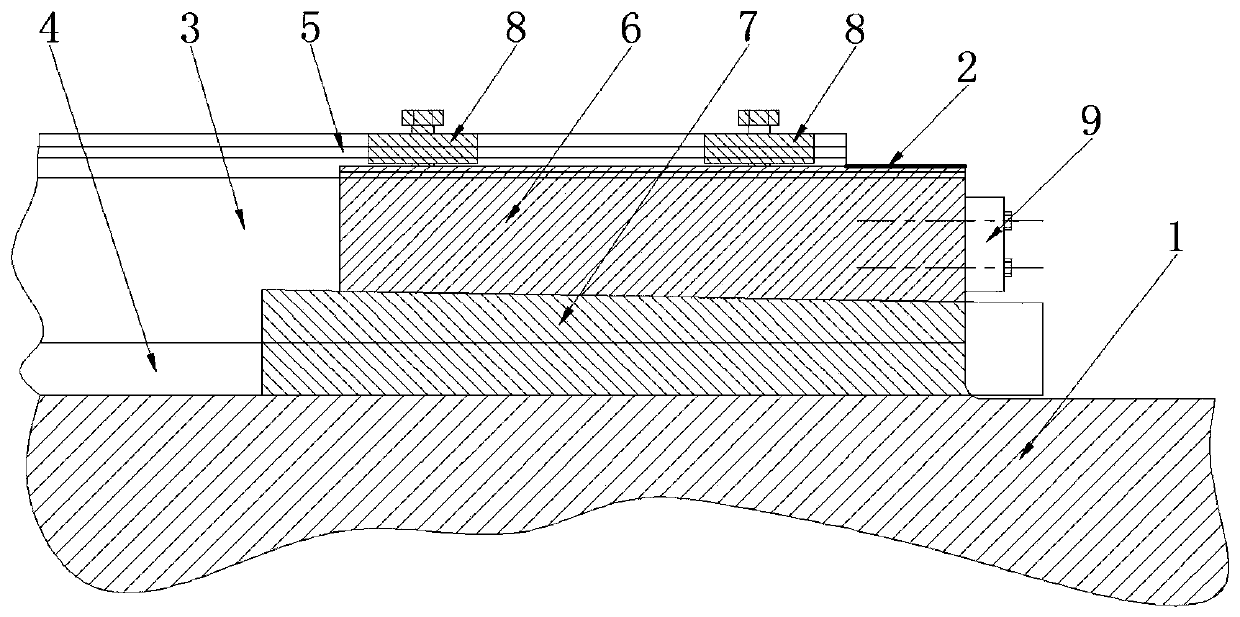

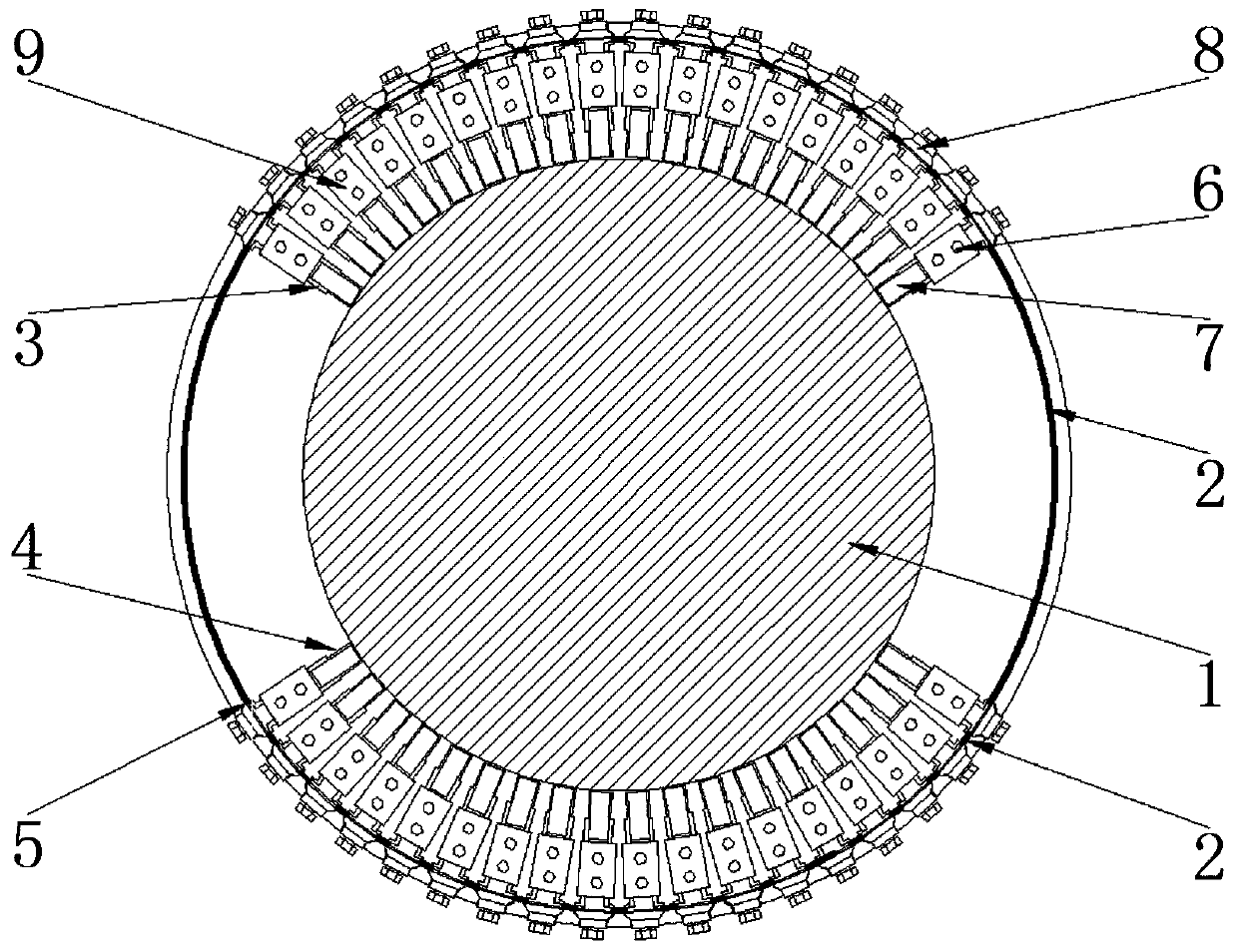

[0027] Spray plating protection process for the repaired rotor retaining ring seam. Its specific implementation process is as follows:

[0028] 1) During the repair process of rotor 1, it was found that the spray coating layer 2 of the retaining ring was damaged and fell off, and it needed to be sprayed again;

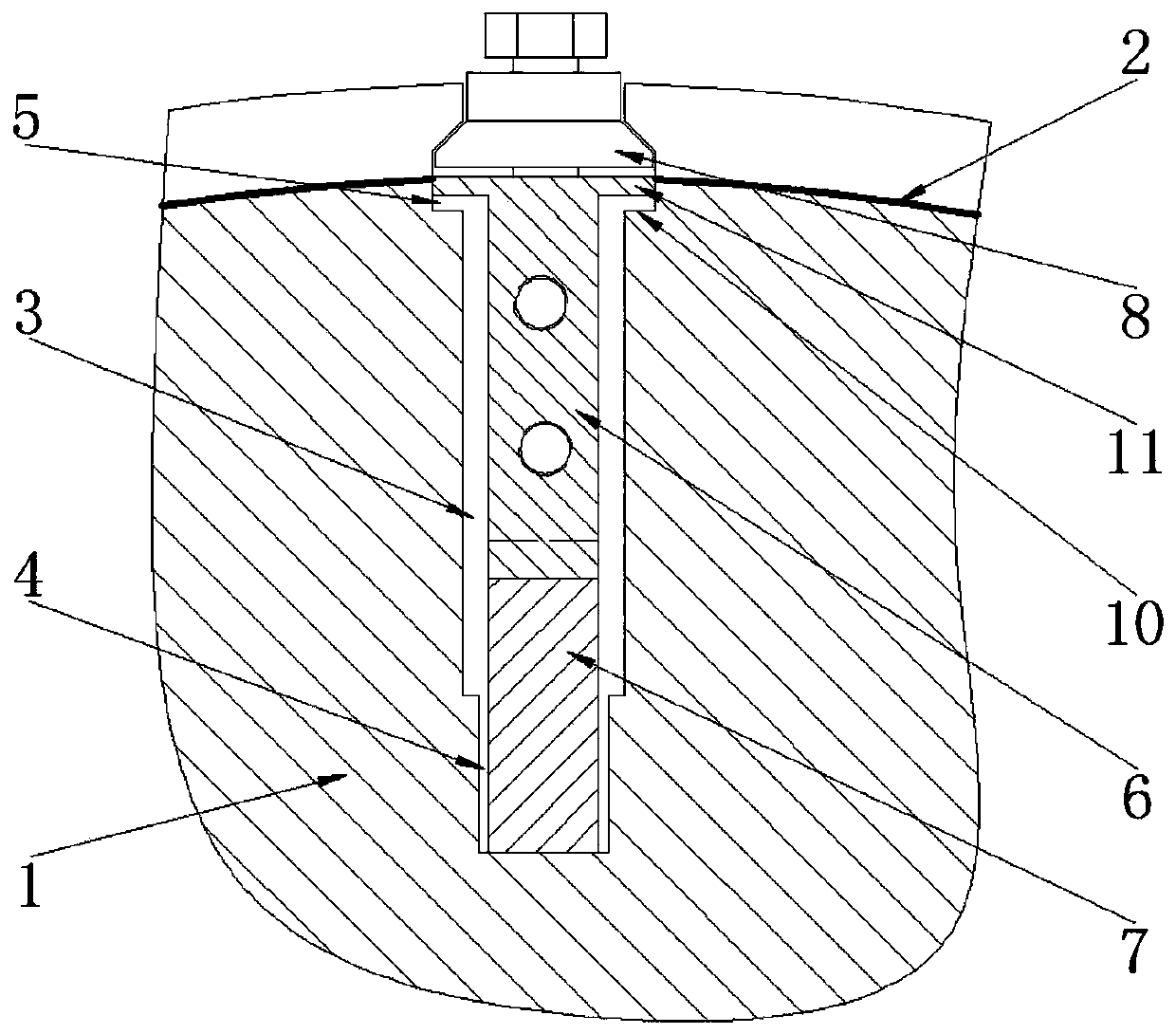

[0029] 2) Remove all the parts in the lower wire slot 3, clean the lower wire slot 3, the auxiliary slot 4, and the dovetail slot 5;

[0030] 3) Due to the high temperature of the material sprayed on the coating layer 2 of the retaining ring stop of the reworked rotor 1 during the spraying operation, the spraying protection tools are all made of metal materials;

[0031] 4) Before installing the protective tool, assemble the upper half wedge 6 and the baffle plate 9 into one;

[0032] 5) Turn the rework rotor 1 to turn the lower wire slot 3 where the protective tool is to be installed to the top 120° range, and install the protective tools one by one to one end of ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com