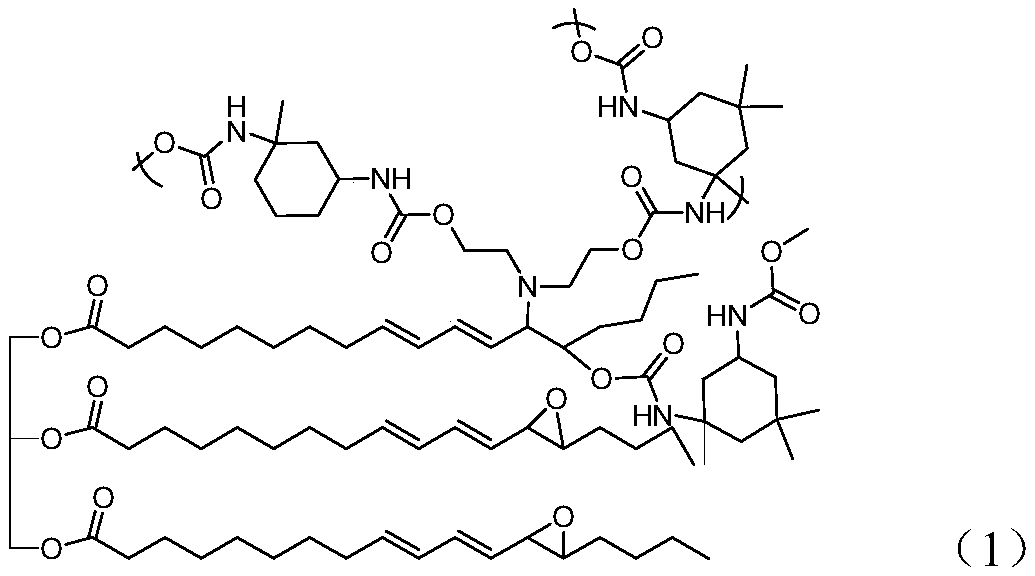

Epoxy tung oil-based waterborne polyurethane modified raw lacquer and preparation method thereof

An oil-based water-based, epoxy tung oil technology, applied in polyurea/polyurethane coatings, natural resin coatings, coatings, etc., can solve the problems of low comprehensive performance of raw lacquer, long surface drying time of paint film, etc., and achieve high impact resistance , light color, good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step 1, the preparation of epoxy tung oil-based water-based polyurethane emulsion:

[0025] Take 44g of tung oil, 50g of petroleum ether, and 3.6g of formic acid and add them into a four-necked reaction flask equipped with an electric stirrer, a thermometer, a dropping funnel, and a condenser, and place it in a constant temperature water bath at 25°C. After stirring at room temperature to disperse evenly, a mixture of 10.2 mL of hydrogen peroxide and 0.44 g of phosphoric acid catalyst was added dropwise at a rate of 20 drops per minute. Since there is exothermic phenomenon in the reaction process, the speed of dropping must be strictly controlled to ensure that the temperature of the system is basically kept stable. After the dropwise addition is completed and the temperature is stable, adjust the temperature of the system to 40°C, stop the reaction after 2 hours, neutralize the reaction mixture to neutrality with saturated sodium bicarbonate, remove the water layer wit...

Embodiment 2

[0033] The difference between this example and Example 1 is that 37.9 g of diphenylmethane diisocyanate is added.

[0034] The performance test results of the modified raw lacquer prepared in this example are basically the same as those in Example 1.

Embodiment 3

[0036] The difference between this embodiment and embodiment 1 is that diphenylmethane diisocyanate is used instead of isophorone diisocyanate.

[0037] The performance test results of the modified raw lacquer prepared in this example are basically the same as those in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap