Self-positioning high-precision aperture measuring device

A measuring device and self-positioning technology, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of poor precision, complex structure, low efficiency, etc., and achieve the effect of fast measurement and correctness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

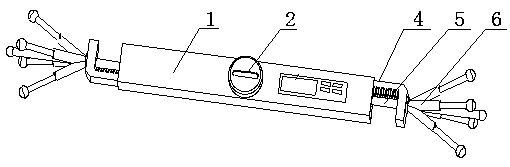

[0026] A self-positioning high-precision aperture measurement device includes a bracket 1, a coarse adjustment knob 2, an adjustable support arm 4, a measuring rod 5, and a self-positioning structure 6. There are two adjustable support arms 4 and two measuring rods 5, and there are two Both ends of 1 are respectively provided with an adjustable support arm 4 and a measuring rod 5, each adjustable support arm 4 is provided with a self-positioning structure 6, and a thick knob is provided on the shell of the support 1. The bracket 1 is provided with a chute; the coarse adjustment knob 2 is located in the center of the bracket 1, and below the coarse adjustment knob 2 is a high-precision straight / helical gear 8, which can be unlocked and locked by pulling it up and pressing it down.

[0027] An electronic module can also be installed on the shell of the bracket 1, which can realize μ-level high-precision distance measurement, and can display the measured value and power percentage...

Embodiment 2

[0030] Such as figure 1 As shown, a self-positioning high-precision aperture measuring device includes a bracket 1, a coarse adjustment knob 2, an adjustable support arm 4, a measuring rod 5, and a self-positioning structure 6. The device utilizes damping rods in the horizontal and vertical directions and The coordinated movement of the universal ball reaches the state of force balance, ensuring that the measured length direction is located in the diameter direction of the radial tangent circle. The linear grating scale is used to achieve fast and accurate measurement of the aperture. This device needs to be used in conjunction with an outer micrometer.

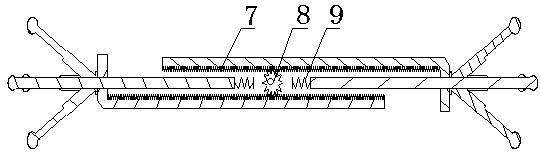

[0031] Coarse adjustment knob 2 includes: coarse adjustment knob 2, high-precision straight / helical gear 8;

[0032] The adjustable support arm 4 includes: the adjustable support arm 4, the straight / helical rack 7 of the support arm;

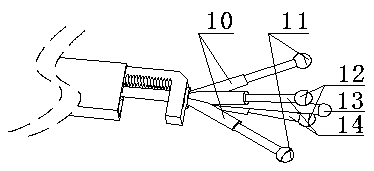

[0033] The self-positioning structure 6 includes: a horizontal damping rod 10, a horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com