Preparation method for nano CT sample of catalytic layer of proton exchange membrane fuel cell

A technology of proton exchange membranes and fuel cells, which is applied in the preparation of test samples, material analysis using wave/particle radiation, and material analysis. To achieve the effect of reducing the difficulty of sample preparation operation, strengthening the value of engineering application, and reducing processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] For a better understanding of the present invention, the following examples are further descriptions of the present invention, but the content of the present invention is not limited to the following examples.

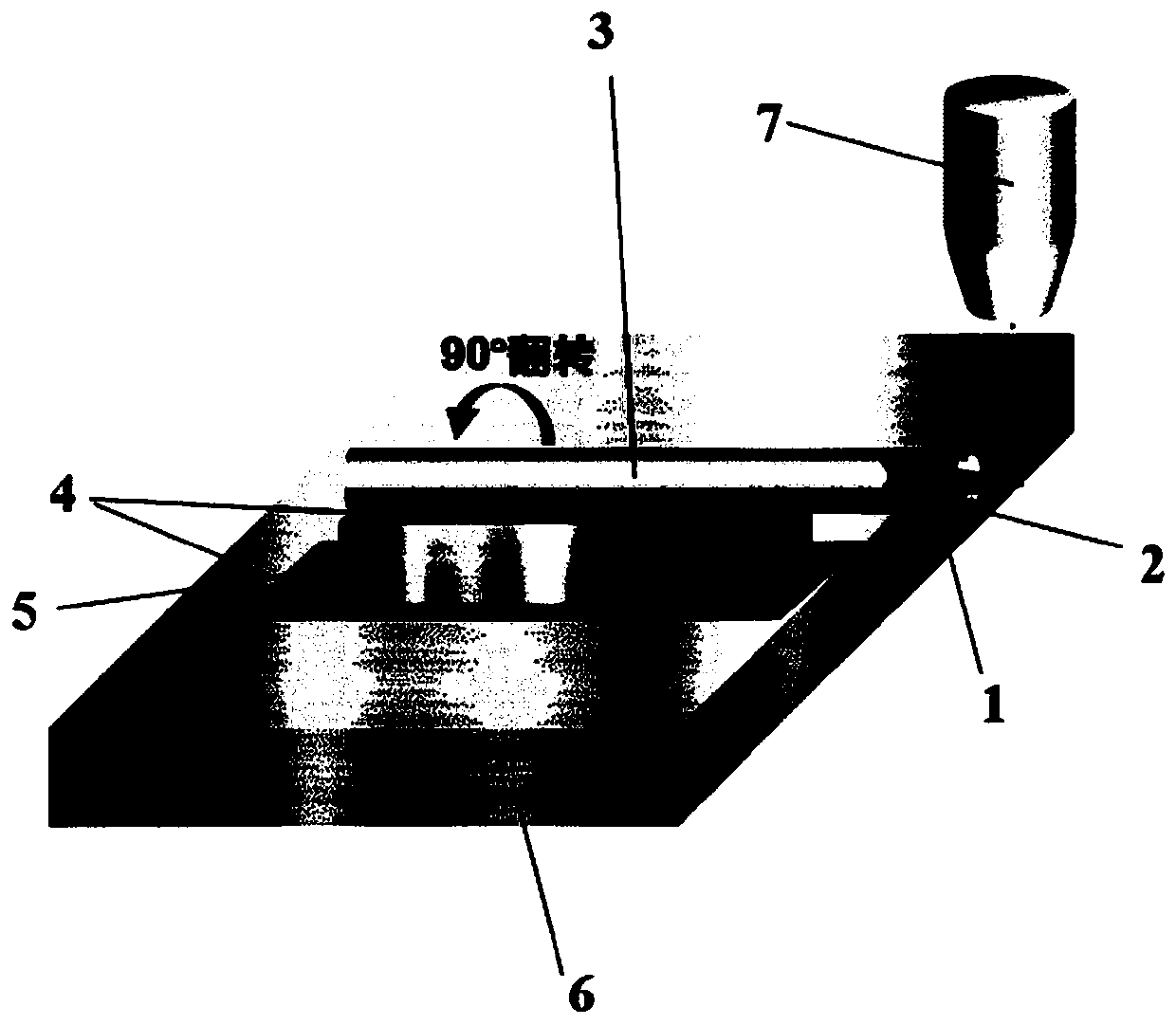

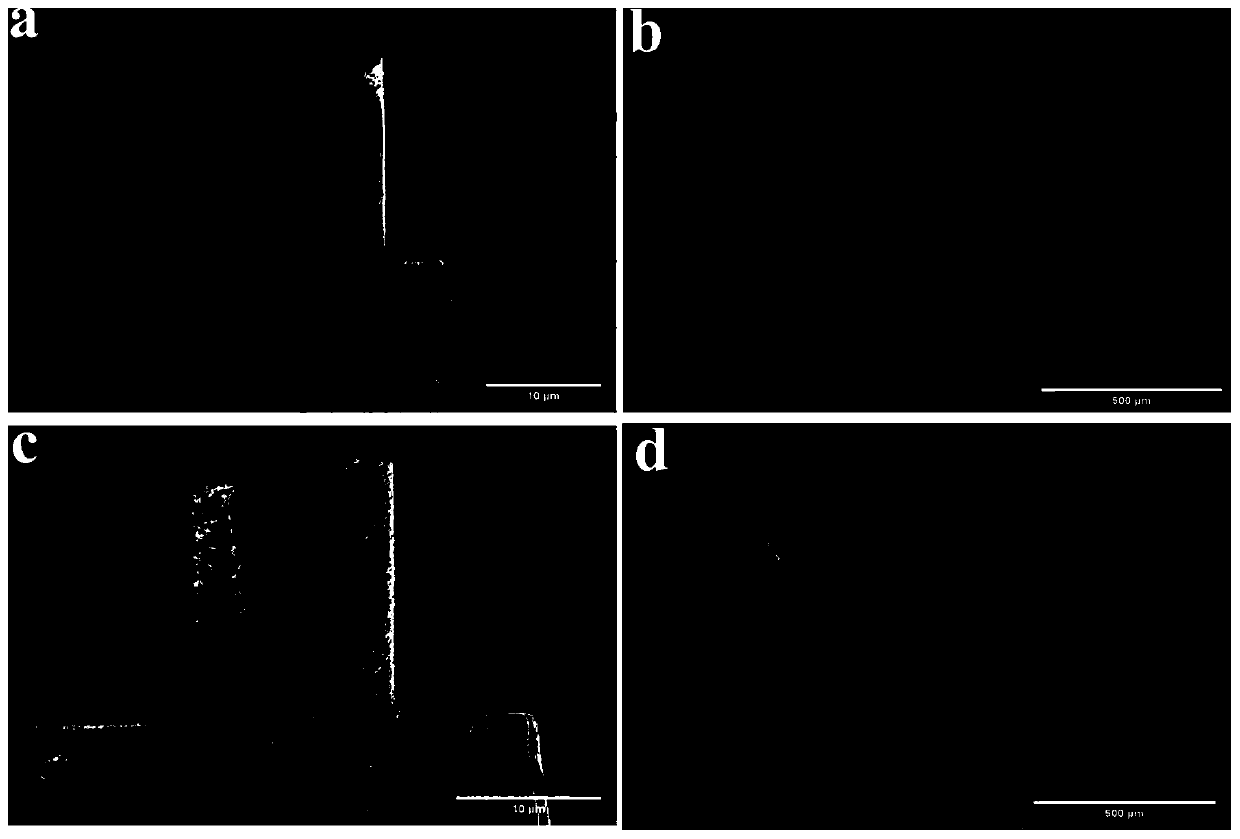

[0031] In this embodiment, the nano-CT sample of the commercial standard proton exchange membrane fuel cell catalyst layer derived from Wuhan University of Technology New Energy Company was successfully prepared by using the method of the present invention. figure 1 It is the TEM figure of the proton exchange membrane cathode catalytic layer of the present invention, as can be seen from the figure, the catalytic layer has a complex pore structure, and the pore size distribution is approximately between 10-1um; it is prepared by the following steps:

[0032] First, a large piece of CCM sample is cut with a scalpel into a CCM sample strip 1 with a sharp tip, and then screened under an optical microscope to keep a CCM sample strip 1 with a tip width of less than 60 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com