LILI bean and processing method thereof

A processing method and technology for raw beans, which are applied in the field of food processing, can solve the problems of skin breakage and short processing time of beans, and achieve the effects of ensuring the integrity of the particles, improving the sensory properties, and shortening the cooking time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

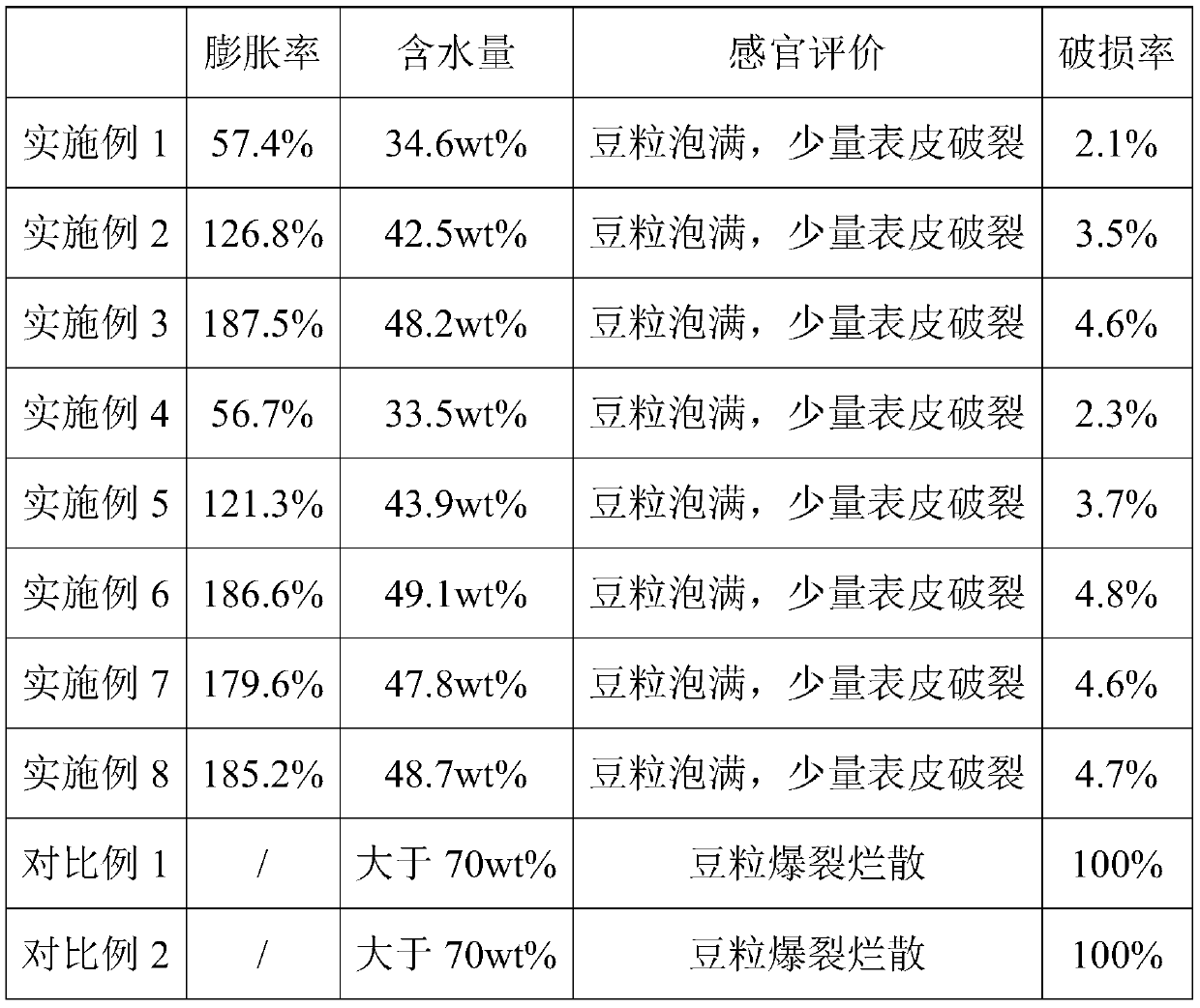

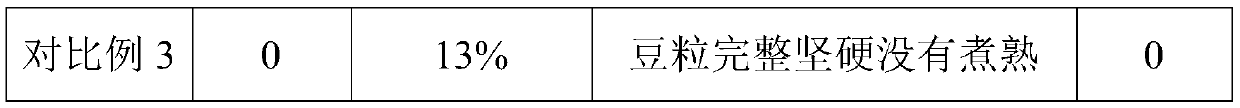

Examples

Embodiment 1

[0040] Embodiment 1 A kind of salty red bean and preparation method thereof

[0041] 1) Weigh 50 kg of selected red bean, wash and set aside.

[0042] 2) Put the cleaned red beans into a container with a hole, and then cover the mouth of the container tightly. The aperture of the hole is smaller than the particle size of the red beans to avoid leakage of the red beans. The capacity of the container is 0.065m 3 .

[0043] 3) Prepare 250kg of 2wt% salt solution, and add the prepared solution to a volume of 3m 3 in an upright pressure cooker.

[0044] 4) Then place the container with the red bean in step 3) in the vertical pressure cooker filled with the saline solution, and the saline solution completely submerges the container with the red bean.

[0045] 5) The pressure of the vertical pressure cooker is increased to 0.1MPa-0.2MPa, the temperature is raised to 121°C-125°C, and cooking is carried out at the pressure and temperature for 40 minutes.

[0046] 6) Stop pressurizati...

Embodiment 2

[0047] Embodiment 2 A kind of salty red bean and preparation method thereof

[0048] 1) Weigh 50 kg of selected red bean, wash and set aside.

[0049] 2) Put the cleaned red beans into a container with a hole, and then cover the container tightly. The aperture of the hole is smaller than the particle size of the red beans to avoid leakage of the red beans. The capacity of the container is 0.08m 3 .

[0050] 3) Prepare 200kg of 2wt% salt solution, and add the prepared solution to a volume of 3m 3 in an upright pressure cooker.

[0051] 4) Then place the container with the red bean in step 3) in the vertical pressure cooker filled with the saline solution, and the saline solution completely submerges the container with the red bean.

[0052] 5) Increase the pressure of the vertical pressure cooker to 0.1 MPa to 0.2 MPa, and the temperature to 121° C. to 125° C., and cook at the pressure and temperature for 50 minutes.

[0053] 6) Stop pressurization and heating, after the pr...

Embodiment 3

[0054] Embodiment 3 A kind of salty red bean and preparation method thereof

[0055] 1) Weigh 50 kg of selected red bean, wash and set aside.

[0056] 2) Put the cleaned red bean into a container with a hole, and then cover the container tightly. The aperture of the hole is smaller than the particle size of the red bean to avoid leakage of the red bean. The capacity of the container is 0.09m 3 .

[0057] 3) Prepare 200kg of 2wt% salt solution, and add the prepared solution to a volume of 3m 3 in an upright pressure cooker.

[0058] 4) Then place the container with the red bean in step 3) in the vertical pressure cooker filled with the saline solution, and the saline solution completely submerges the container with the red bean.

[0059] 5) Increase the pressure of the vertical pressure cooker to 0.1 MPa to 0.2 MPa, and the temperature to 121° C. to 125° C., and cook at the pressure and temperature for 50 minutes.

[0060] 6) Stop pressurization and heating, after the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com