Core welding-wire material and preparation method thereof

A technology of welding core and allowance, applied in welding/cutting medium/material, welding equipment, welding medium, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

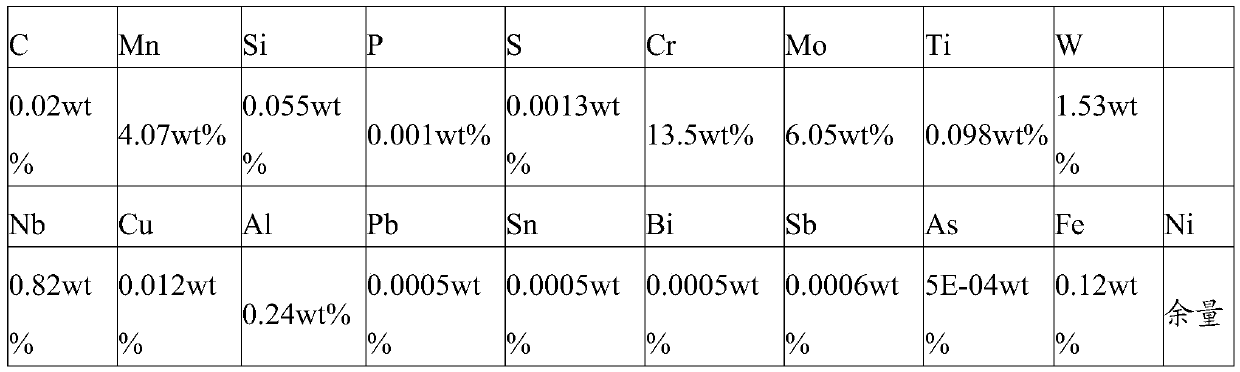

Embodiment 1

[0068] Metal nickel, metal chromium, metal tungsten, metal molybdenum and 2 / 3 carbon are put into the furnace at one time, the remaining 1 / 3 carbon is added after the alloy liquid is completely melted and before refining, and metal aluminum, sponge titanium and metal niobium are added after refining , metal manganese and nickel-magnesium alloy are added before tapping for vacuum induction melting; during the charging process, the vacuum furnace is filled with 50 torr of argon before metal manganese is added;

[0069] The deoxidation method in the vacuum induction smelting process is: sequentially carry out carbon deoxidation, Al deoxidation, Ce deoxidation and Mg deoxidation; the vacuum degree in the deoxidation process is 1Pa;

[0070] The desulfurization method in the vacuum induction smelting process is as follows: slag desulfurization, Ce desulfurization and Mg desulfurization are carried out in sequence; the vacuum degree in the desulfurization process is 1 Pa;

[0071] T...

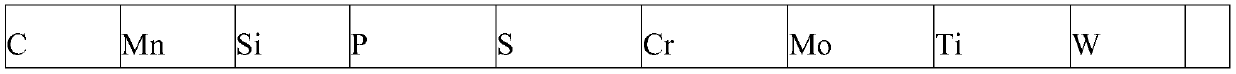

Embodiment 2

[0087] Metal nickel, metal chromium, metal tungsten, metal molybdenum and 2 / 3 carbon are put into the furnace at one time, the remaining 1 / 3 carbon is added after the alloy liquid is completely melted and before refining, and metal aluminum, sponge titanium and metal niobium are added after refining , metal manganese and nickel-magnesium alloy are added before tapping for vacuum induction melting; during the charging process, the vacuum furnace is filled with 50 torr of argon before metal manganese is added;

[0088] The deoxidation method in the vacuum induction smelting process is: sequentially carry out carbon deoxidation, Al deoxidation, Ce deoxidation and Mg deoxidation; the vacuum degree in the deoxidation process is 1Pa;

[0089] The desulfurization method in the vacuum induction smelting process is as follows: slag desulfurization, Ce desulfurization and Mg desulfurization are carried out in sequence; the vacuum degree in the desulfurization process is 1Pa;

[0090] Th...

Embodiment 3

[0107] Metal nickel, metal chromium, metal tungsten, metal molybdenum and 2 / 3 carbon are put into the furnace at one time, the remaining 1 / 3 carbon is added after the alloy liquid is completely melted and before refining, and metal aluminum, sponge titanium and metal niobium are added after refining , metal manganese and nickel-magnesium alloy are added before tapping for vacuum induction melting; during the charging process, the vacuum furnace is filled with 50 torr of argon before metal manganese is added;

[0108] The deoxidation method in the vacuum induction smelting process is: sequentially carry out carbon deoxidation, Al deoxidation, Ce deoxidation and Mg deoxidation; the vacuum degree in the deoxidation process is 1Pa;

[0109] The desulfurization method in the vacuum induction smelting process is as follows: slag desulfurization, Ce desulfurization and Mg desulfurization are carried out in sequence; the vacuum degree in the desulfurization process is 1Pa;

[0110] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com