A heat dissipation grinding device with the function of measuring the temperature of the grinding surface

A temperature measurement and grinding surface technology, which is applied in the direction of grinding/polishing safety devices, grinding machine parts, grinding/polishing equipment, etc., can solve the problem that it is difficult to directly measure the temperature of the contact surface and cannot detect the temperature of the grinding surface in real time , energy waste and other issues, to achieve the effect of lowering the temperature, improving the service life and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] Further description will be made below in conjunction with drawings and embodiments.

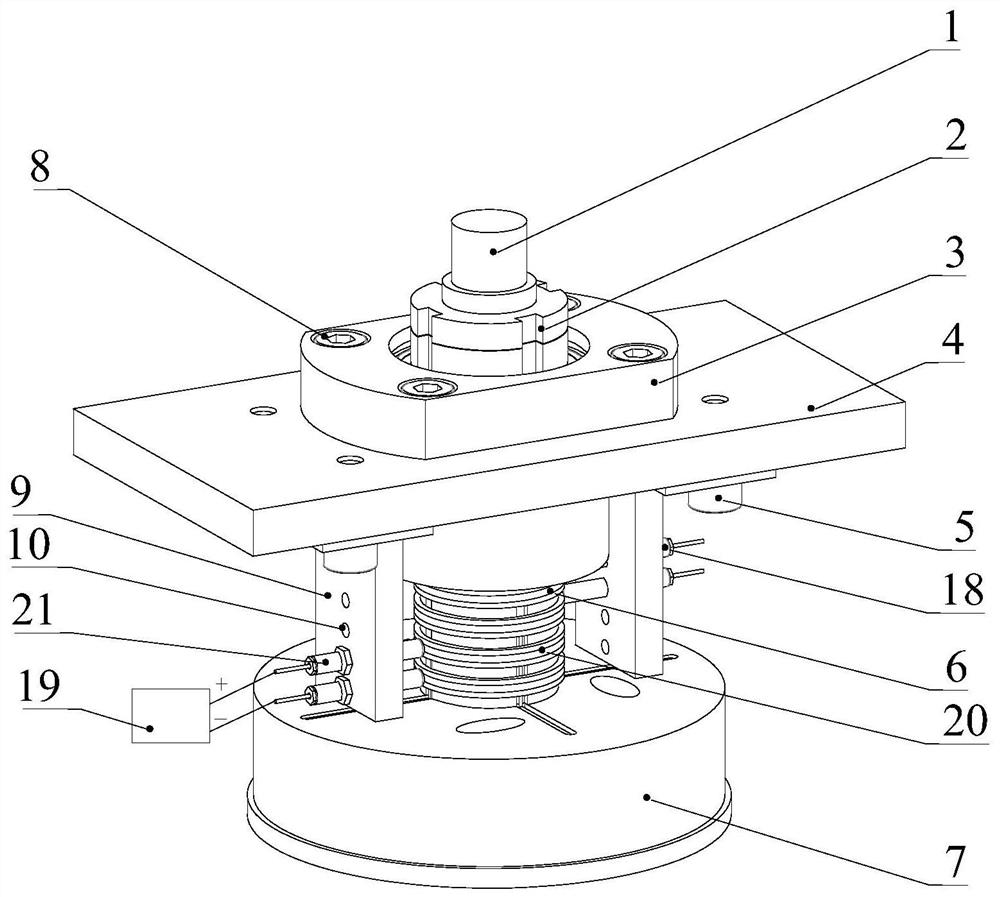

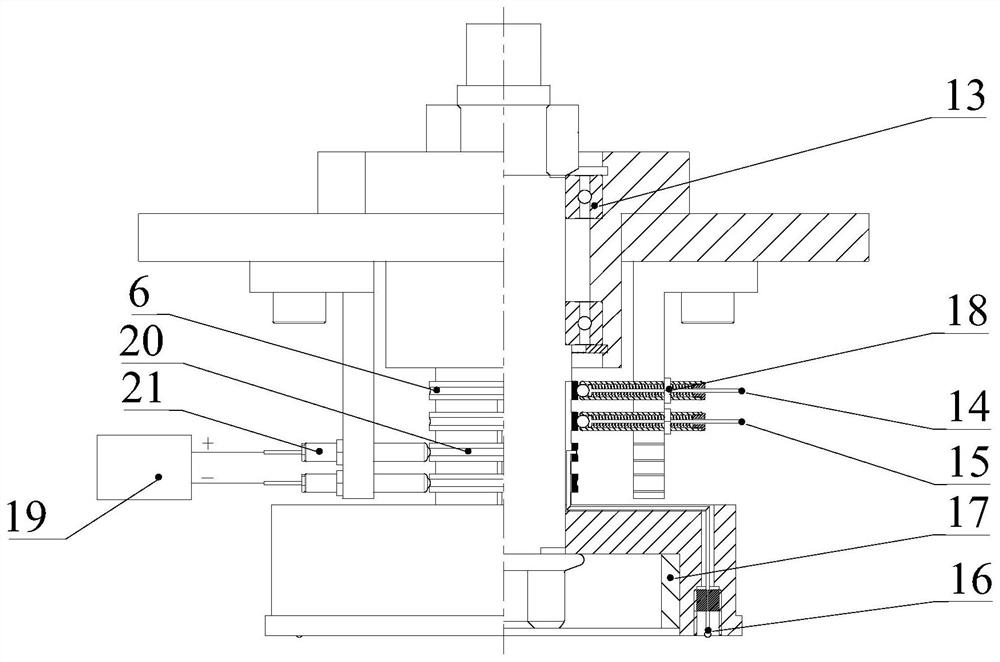

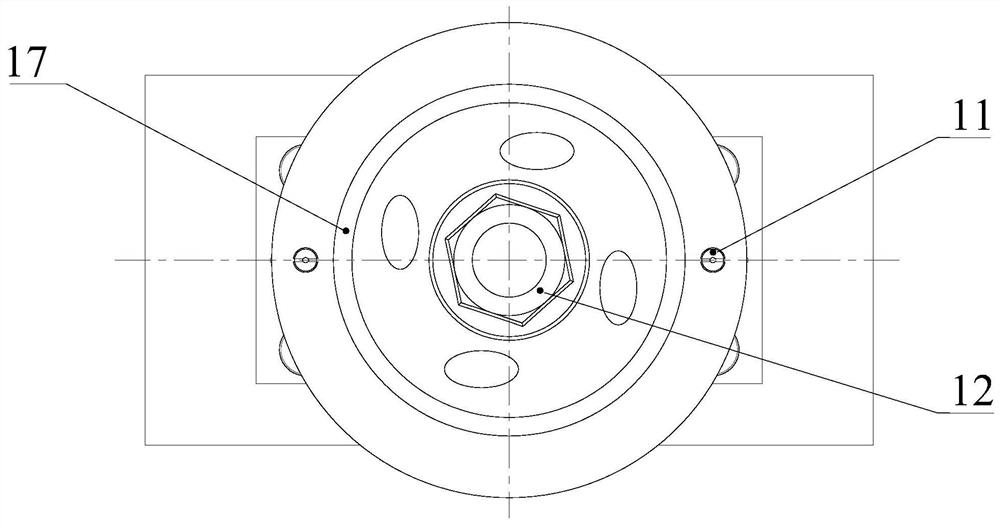

[0041] The invention provides a heat dissipation grinding device (grinding device for short, refer to Figure 1-13 ), including the main shaft 1, the bearing seat 3, the first fixed plate 4, the first ring 6, the grinding wheel 7, the second fixed plate 9, the thermocouple 16, the cooling ring 17, two conductive first ball brushes 18, Two conductive second ball brushes 21, temperature collector 19, second annulus 20 and controller (not shown in the figure);

[0042]The bearing seat 3 is installed on the first fixed plate 4 through the second bolt 8, the main shaft 1 is installed in the bearing seat 3 through the bearing 13, the upper end of the main shaft 1 is axially limited by the lock nut 2 to the main shaft 1, and the second The bottom of a fixed plate 4 is equipped with a second fixed plate 9 for installing the first ball brush 18 and the second ball brush 21 through the first b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com