Graphite double-covering production device

A production equipment, double edge technology, applied in the direction of stone processing equipment, stone processing tools, work accessories, etc., can solve the problems of low mechanical shearing accuracy, bending or discounting, high impact on the qualified rate of finished products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described in detail below in conjunction with the drawings.

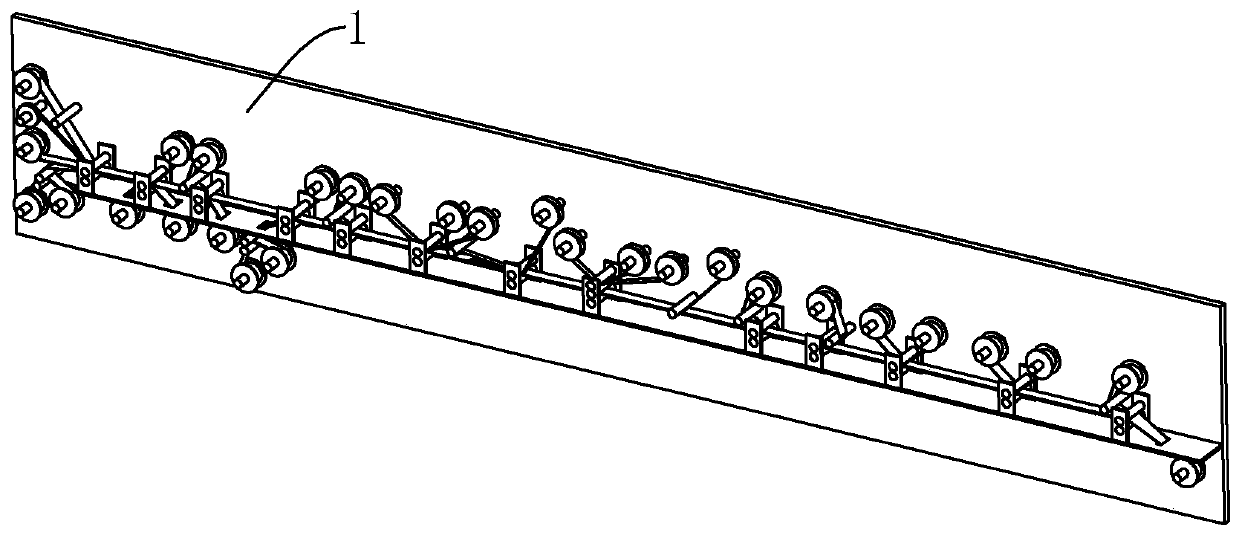

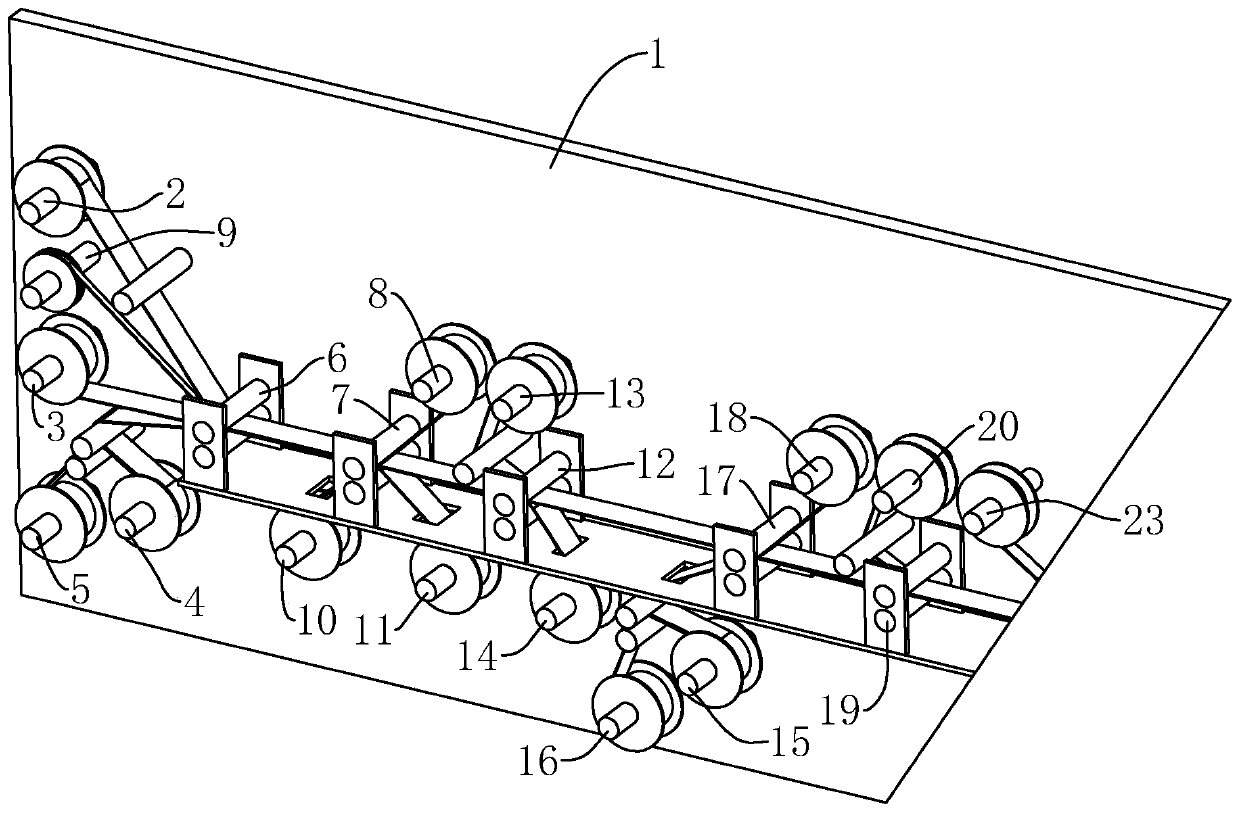

[0066] Reference figure 1 , Is a kind of graphite double edging production equipment disclosed in the present invention, including a wall 1 arranged with a driving device for driving the entire device, the driving device is selected as a motor, and the entire device is driven by the motor .

[0067] Reference figure 2 A graphite arrangement drum 2 is installed on the arrangement wall 1, and the graphite arrangement drum 2 is sleeved with a graphite material plate for winding a graphite strip.

[0068] A first paper backing drum 3 and a second paper backing drum 4 are installed on the layout wall 1. The first paper backing drum 3 is arranged on the upper side of the second paper backing drum 4, and the first paper backing drum 3 and the second paper liner drum 4 are wound with a first paper liner and a second paper liner. The first paper liner is wound with a first paper liner,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com