Deicing pantograph bow suitable for T-shaped rigid catenary system

A rigid contact and bow head technology, applied in the field of rail transit, can solve problems such as water seepage, excessive wear of deicing devices, and easy icing of rigid contact nets, so as to reduce violent shaking, avoid water accumulation and freezing, and avoid collapse of nets. effect of accident

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

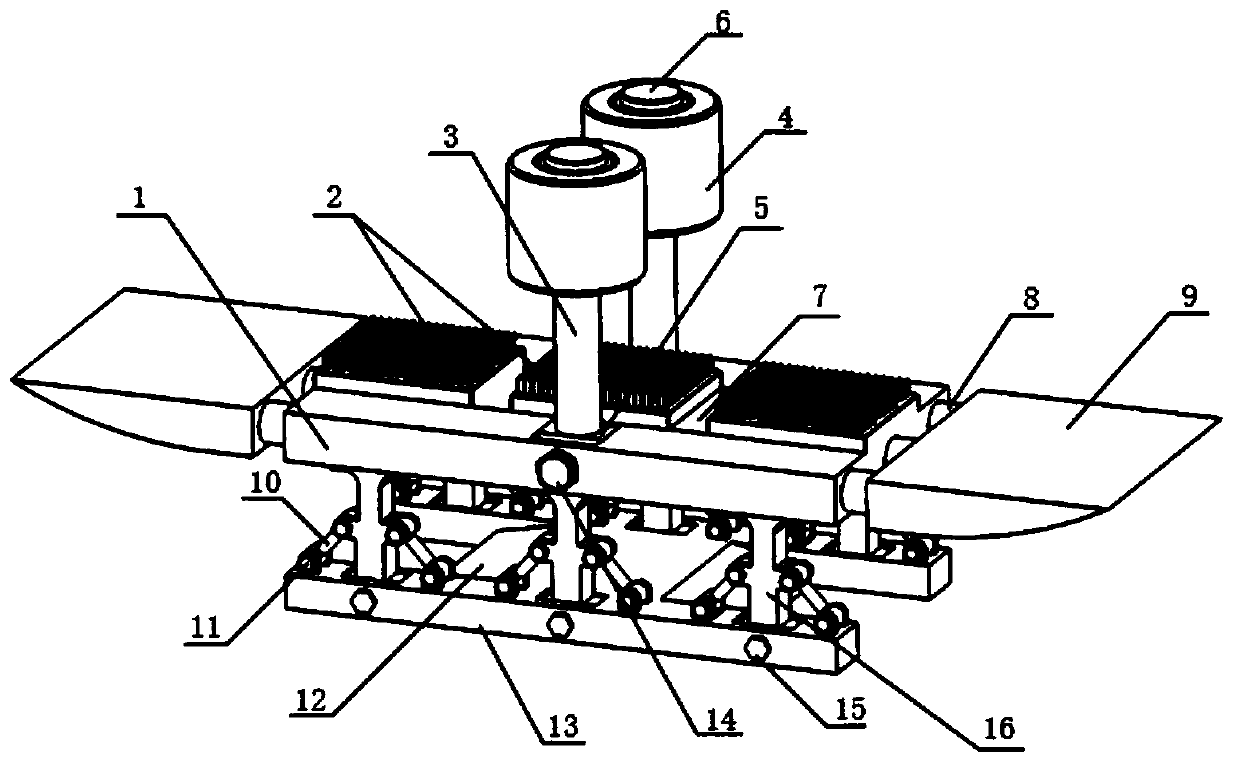

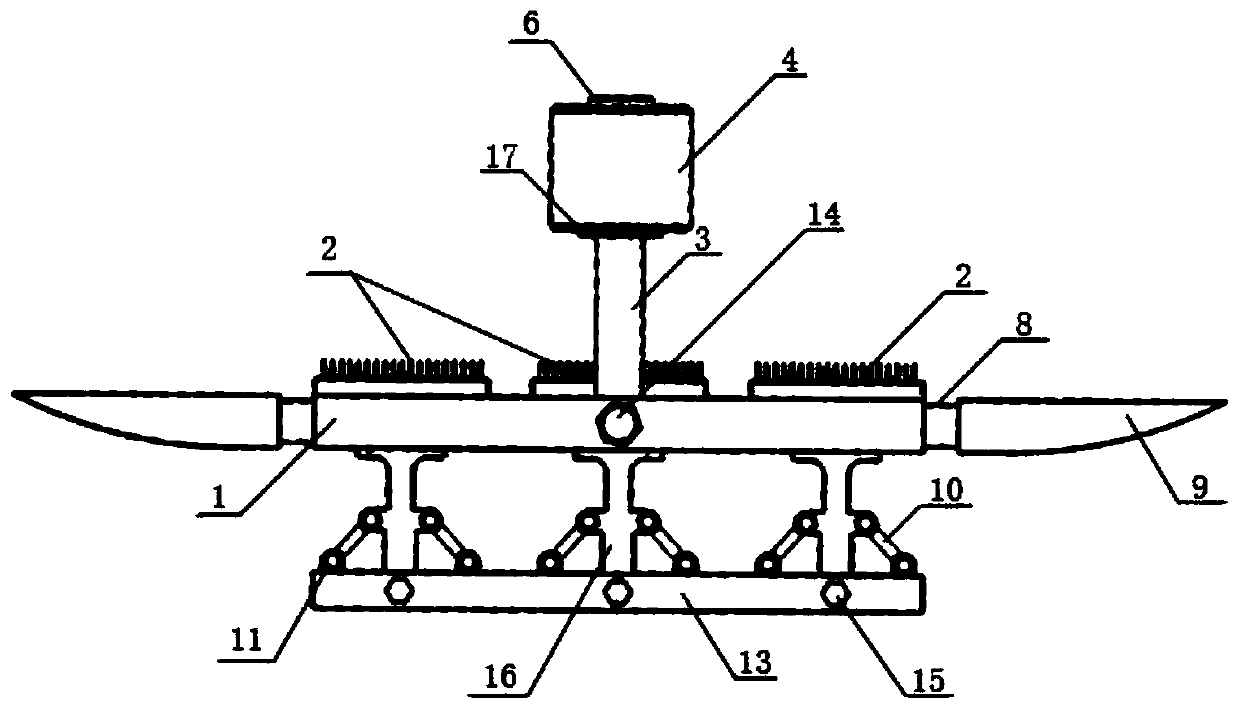

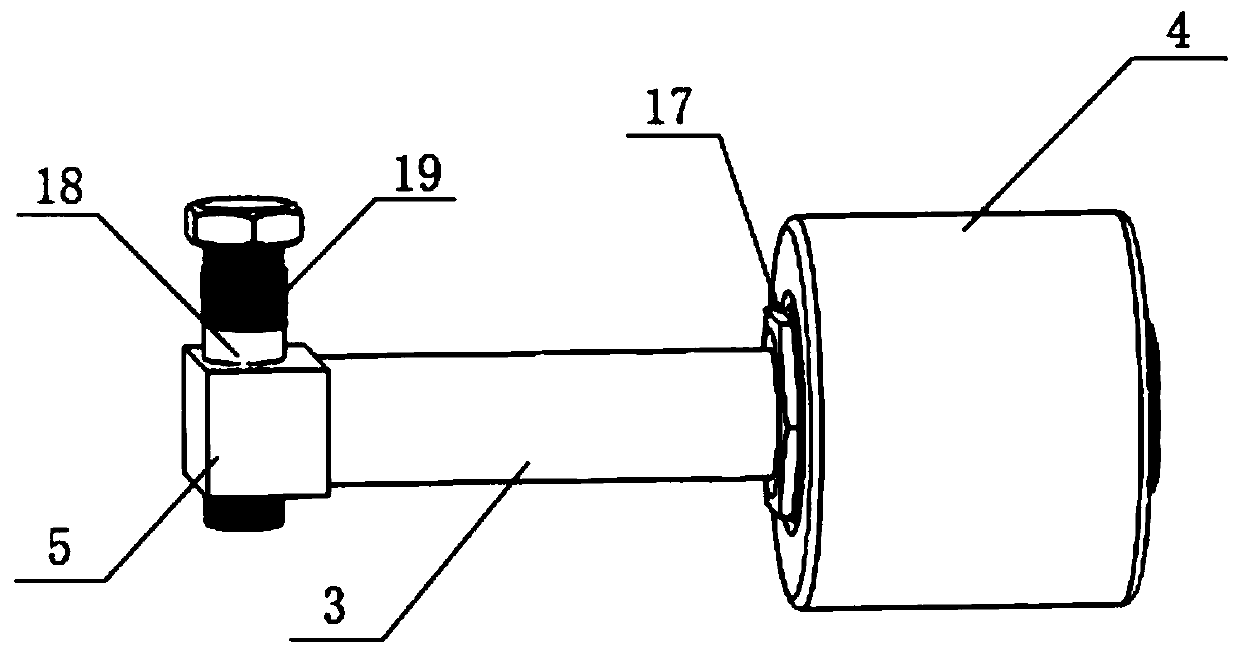

[0028] Figure 5 figure 1 It shows that a "T" type rigid contact current receiving device suitable for alpine regions and tunnels is composed of a "T" type rigid catenary and a deicing bow; the "T" type rigid catenary is composed of multiple suspension mechanisms and The bus bar 26 and the contact wire 29 are composed, wherein, the cross-sectional shape of the bus bar 26 is a "T" shape composed of a horizontal section and a vertical section, and the cutout at the bottom of the vertical section forms a pair of chucks, and the contact wire 29 The clamping bolt 27 and the clamping nut 28 are clamped on the chuck of the bus bar 26; the suspension mechanism is: T-bolts 23 are respectively fixed at both ends of the channel steel 20, and the tops of the two T-bolts 23 are used for fixing on On the inner wall of the tunnel, the insulator 21 is fixed on the bottom surface of the channel steel 20, the bus bar clamp 22 is fixed on the bottom of the insulator 21 by bolts, and the two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com