Anode gas circulating fan for fuel cell system

A fuel cell system and anode gas technology, applied in liquid fuel engines, electrical components, components of pumping devices for elastic fluids, etc., can solve the problems of series connection, single structure, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

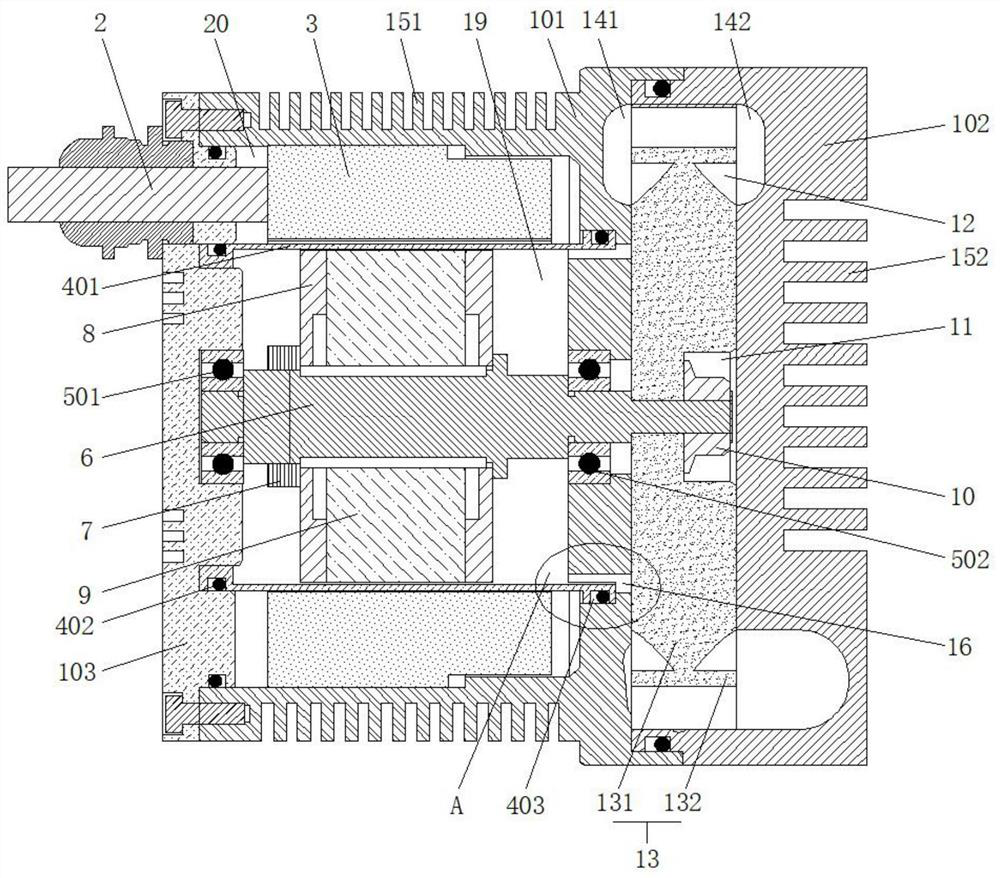

[0038] The operator first installs and fixes the rear cover 103 and the motor casing 101, then installs the stator 3 plastic-sealed with epoxy resin into the inside of the motor casing 101, and then installs the terminal 2 on one end of the motor casing 101 , and between the stator 3 and the terminal 2 are electrically connected, the middle part of the first bearing 501 of the rear cover 103 and the middle part of the second bearing 501 of the motor casing 101 are inserted and fixed with the motor shaft 6, and the middle part of the motor shaft 6 A rotor 9 is installed, and balance weights 8 are installed and fixed on both sides of the rotor 9 through fastening nuts 7;

[0039] One end of the motor shaft 6 is installed and fixed with the impeller 13 through the impeller fastening bolt 10, and the impeller 13 is located inside the impeller groove 12, and the gasket is eliminated, wherein the impeller 13 and the shoulder of the motor shaft 6 fit together, and the shaft of the mot...

Embodiment 2

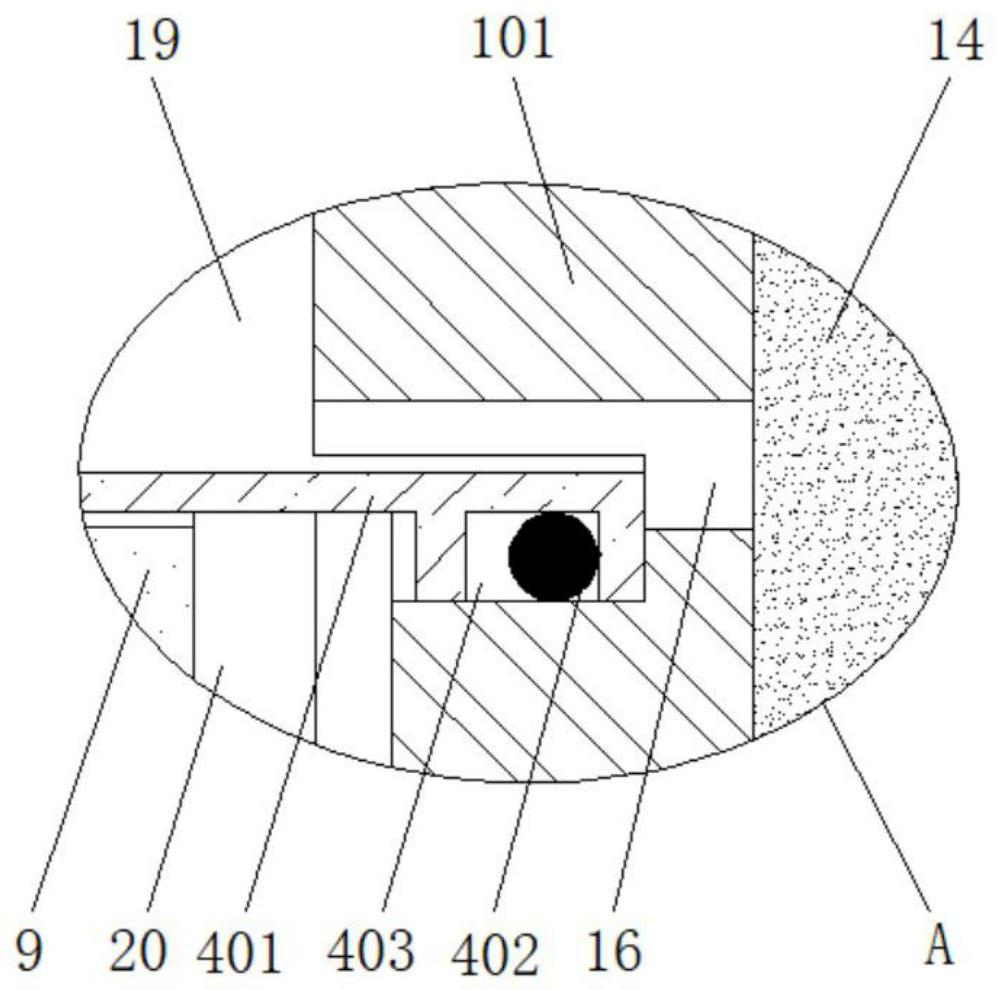

[0044] Wherein, one side of the motor casing 101 is provided with an arc-shaped flow channel a141, and the flow channel a141 is directly opened on the motor casing 101, which can well reduce the overall size of the circulating fan. There is a flow channel b142 on the side, which can better reduce the local kinetic energy loss. This circulation fan can better improve the work efficiency by adopting double-sided flow channels, and the double-sided flow channels can maintain the pressure balance between the two sides of the impeller 13 , reduce the axial force, thereby improving the service life of the bearing;

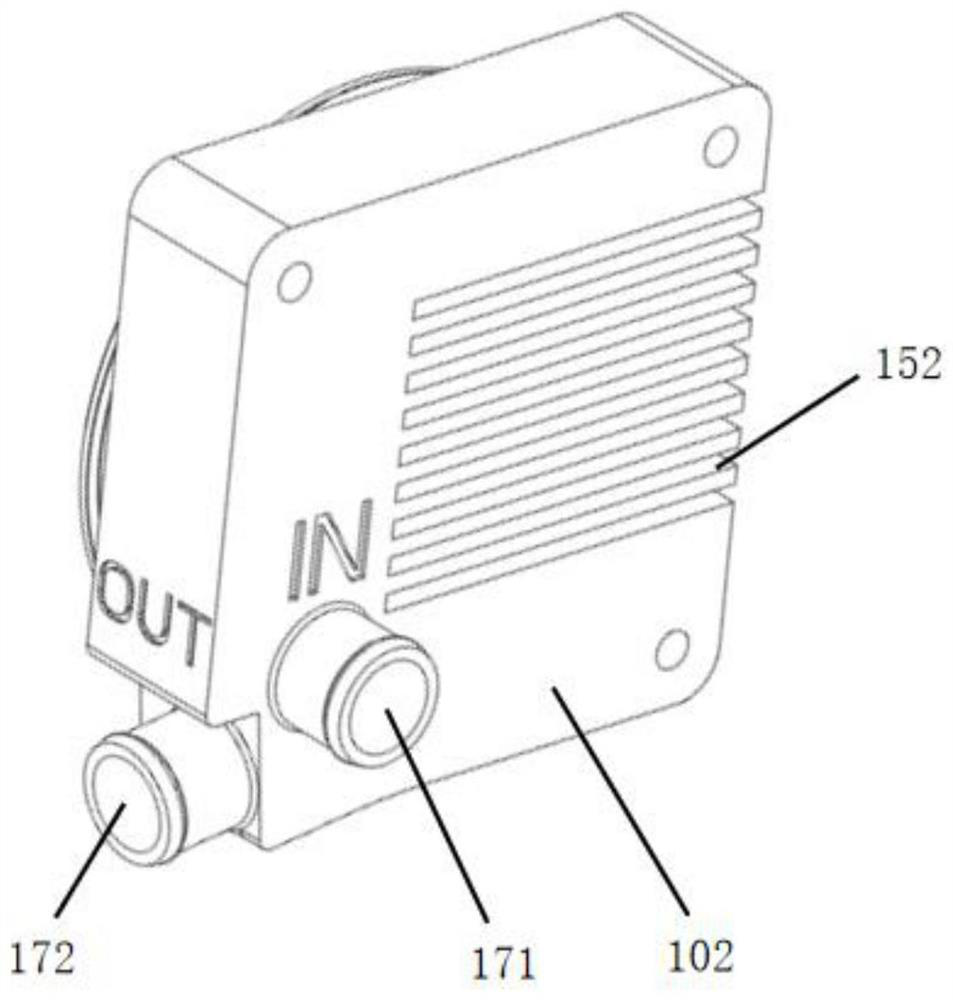

[0045] Further, one side of the flow channel b142 is respectively provided with an air inlet 171 and an air outlet 172 perpendicular to each other, and the junction of the air inlet 171 and the flow channel b142 is an upturned arc transition, which can reduce local kinetic energy loss, The air outlet 172 is designed along the direction of the flow channel b142, which can...

Embodiment 3

[0047] The waterproof bolt groove 11 is directly arranged inside the impeller 13, so that when the head of the circulating fan is placed upside down, the liquid water will form water accumulation in the fan casing 102, reducing the load on the motor, thereby avoiding the overload of the motor occur;

[0048] Wherein, the impeller 13 includes air guide ribs 131 and blades 132, the blades 132 are arranged obliquely clockwise along the central position of the impeller 13, and the included angle between the blades 132 and the central position of the impeller 13 is 1°-85°, and the air guide ribs 131 Cooperating with the blades 132 can guide the direction of the airflow and avoid energy loss caused by local backflow, thereby greatly improving the working efficiency of the impeller 13;

[0049] One side of the motor casing 101 penetrates the inside of the motor rotor air cavity 19 and the impeller groove 12 through the vent hole 16. On the one hand, the internal pressure of the motor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com