Sewage treatment system reconstruction method

A sewage treatment system and sewage treatment technology, applied in biological water/sewage treatment, water/sludge/sewage treatment, biological treatment devices, etc., can solve problems such as rising construction costs, and achieve small footprint and sewage treatment capacity. The effect of speeding up the reconstruction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

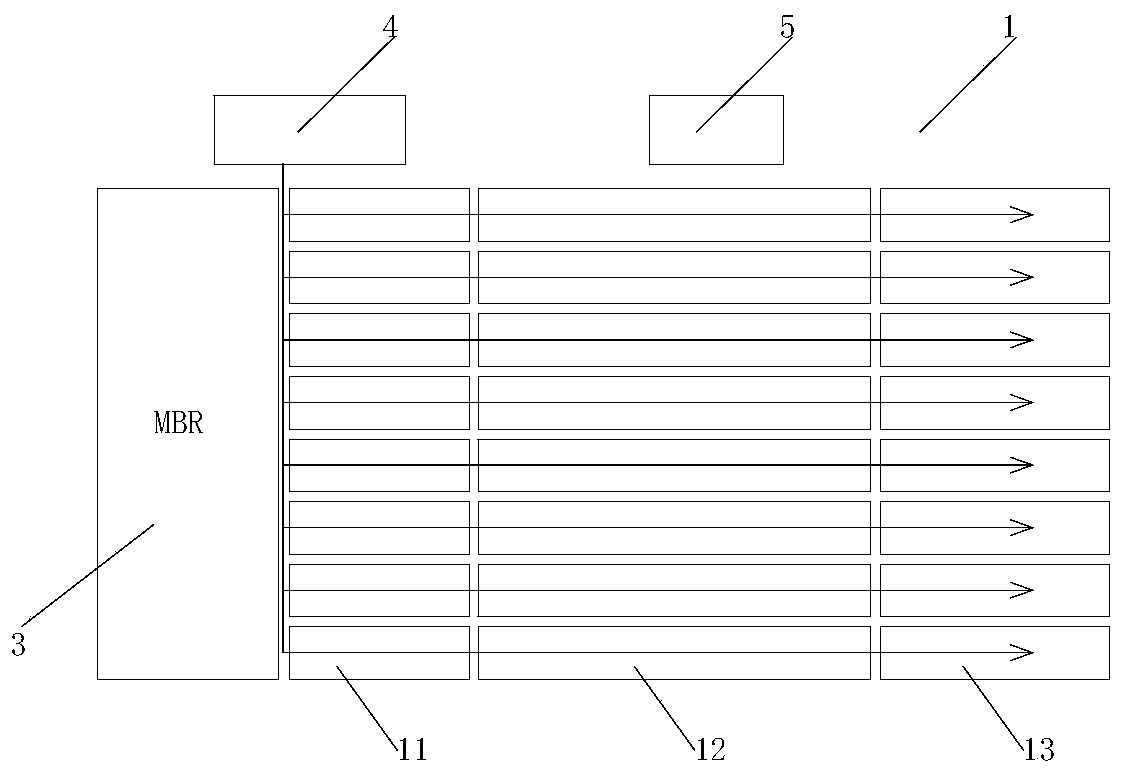

[0026] Example one, such as Figure 1 to Figure 4 Shown:

[0027] Such as figure 1 As shown, the MBR reaction tank 3 is correspondingly arranged at the side position of all the existing primary sedimentation tanks 11, and only the MBR reaction tank 3 is directly used for sewage treatment;

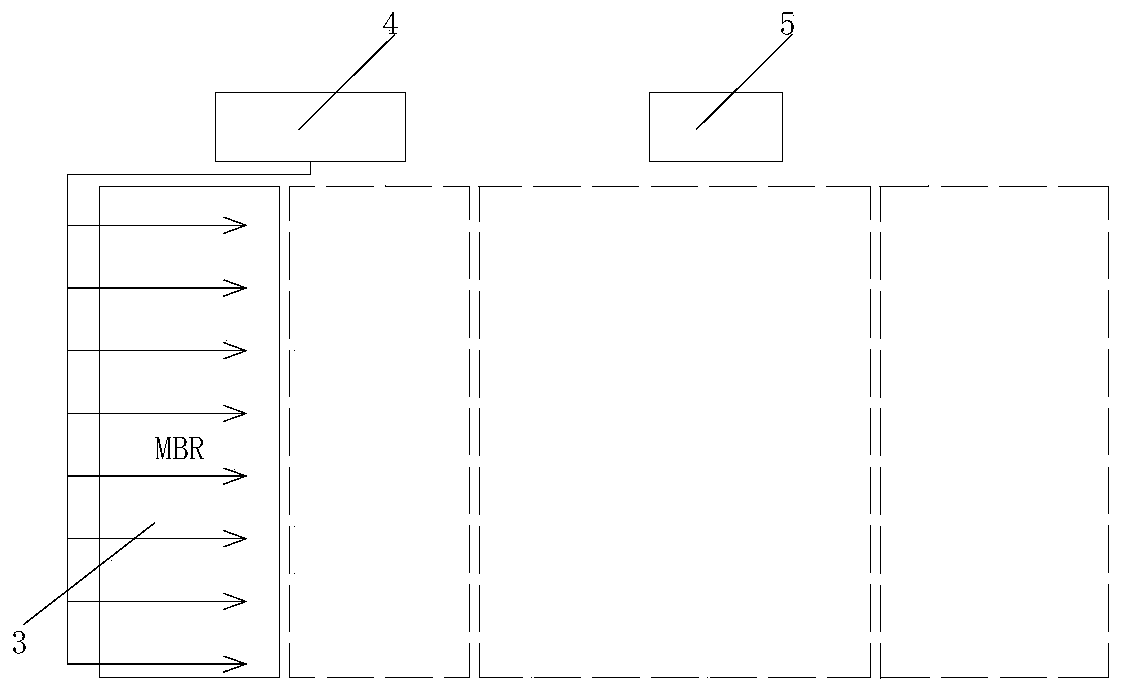

[0028] Such as figure 2 As shown, the existing primary sedimentation tank 11, the existing biological reaction tank 12 and the existing final sedimentation tank 13 are all removed;

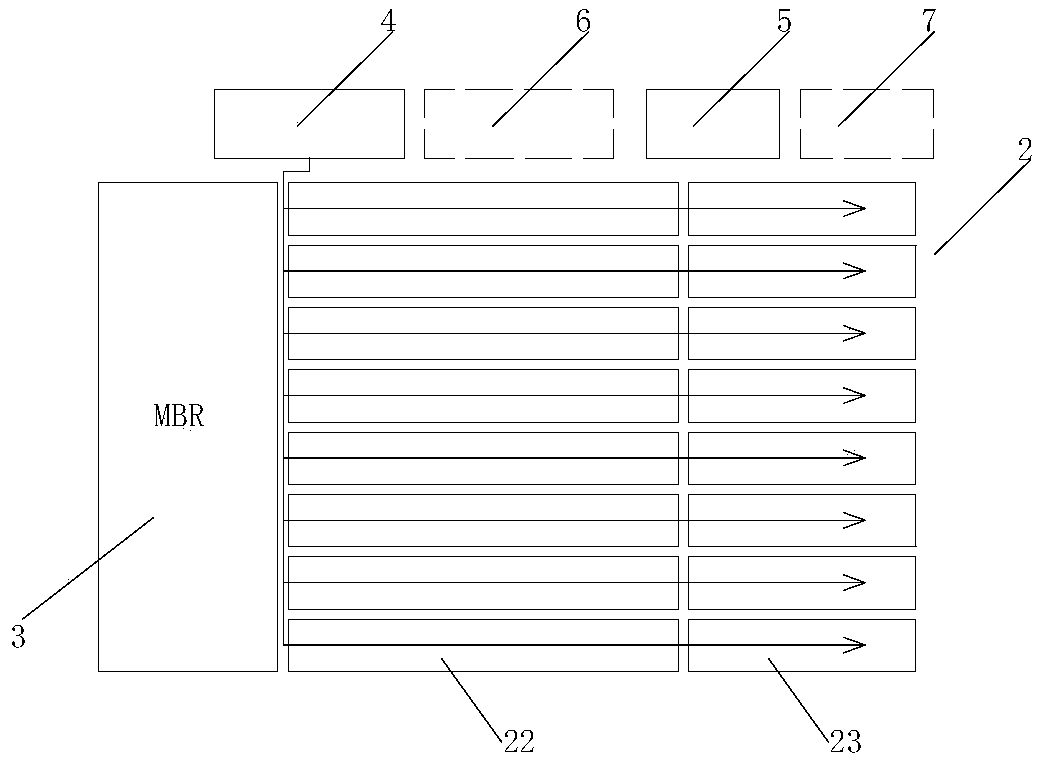

[0029] Such as image 3 As shown, the MBR reaction tank 3 is followed by successively constructing multiple new biological reaction tanks 22 and multiple new final sedimentation tanks 23; the MBR reaction tank 3 is stopped, and multiple newly established biological reaction tanks 22 and multiple new final sedimentation tanks are used. The sedimentation tank 23 is used for sewage treatment; in this step, the primary sedimentation tank is not used for sewage treatment temporarily, although part of the primary sedimenta...

Embodiment 2

[0031] Example two, such as Figure 5 to Figure 11 Shown:

[0032] Such as Figure 5 with Image 6 As shown, the MBR reaction tank 3 is correspondingly set at a side position of a part of the existing primary sedimentation tank 11, and the MBR reaction tank 3 and this part of the existing primary sedimentation tank 11 belong to the existing sewage treatment device 1 for sewage treatment; The existing primary sedimentation tank 11, the existing biological reaction tank 12 and the existing final sedimentation tank 13 of the remaining existing sewage treatment device 1 are all removed; as a further preferred solution, all the existing primary sedimentation tanks 11 are equally divided from the middle There are two groups, the MBR reaction tank 3 is correspondingly set beside the existing primary sedimentation tank 11 in one of them, and the two phases are demolished and constructed twice;

[0033] Such as Figure 7 As shown, a new initial sedimentation tank 21 was built at a position ...

Embodiment 3

[0036] Example three, such as Figure 12 to Figure 17 Shown:

[0037] Such as Picture 12 with Figure 13 As shown, the MBR reaction tank 3 corresponds to the side position of a set of existing sewage treatment devices 1 arranged on the outermost side of the sewage treatment system. The MBR reaction tank 3 and half of the existing sewage treatment devices 1 are used for sewage treatment; In the preferred solution, there are two MBR reaction tanks 3, and the two MBR reaction tanks 3 correspond to the side positions of the existing sewage treatment device 1 on both sides of the sewage treatment system.

[0038] Such as Figure 14 As shown, the existing primary sedimentation tank 11, the existing biological reaction tank 12, and the existing final sedimentation tank 13 of the remaining half of the existing sewage treatment device 1 are all removed, and then half of the new sewage treatment device 2 is built on site;

[0039] Such as Figure 15 with Figure 16 As shown, the MBR reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com