Device, method and application thereof for simulating enrichment form of zinc or alkali metal in upper part of blast furnace

An alkali metal and simulating zinc technology, applied in blast furnace parts, blast furnace, blast furnace details, etc., can solve problems such as inability to accurately understand zinc or alkali metal, and inability to simulate blast furnace atmosphere well, and achieve simple experimental methods and devices. Feasible, high experimental reliability effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

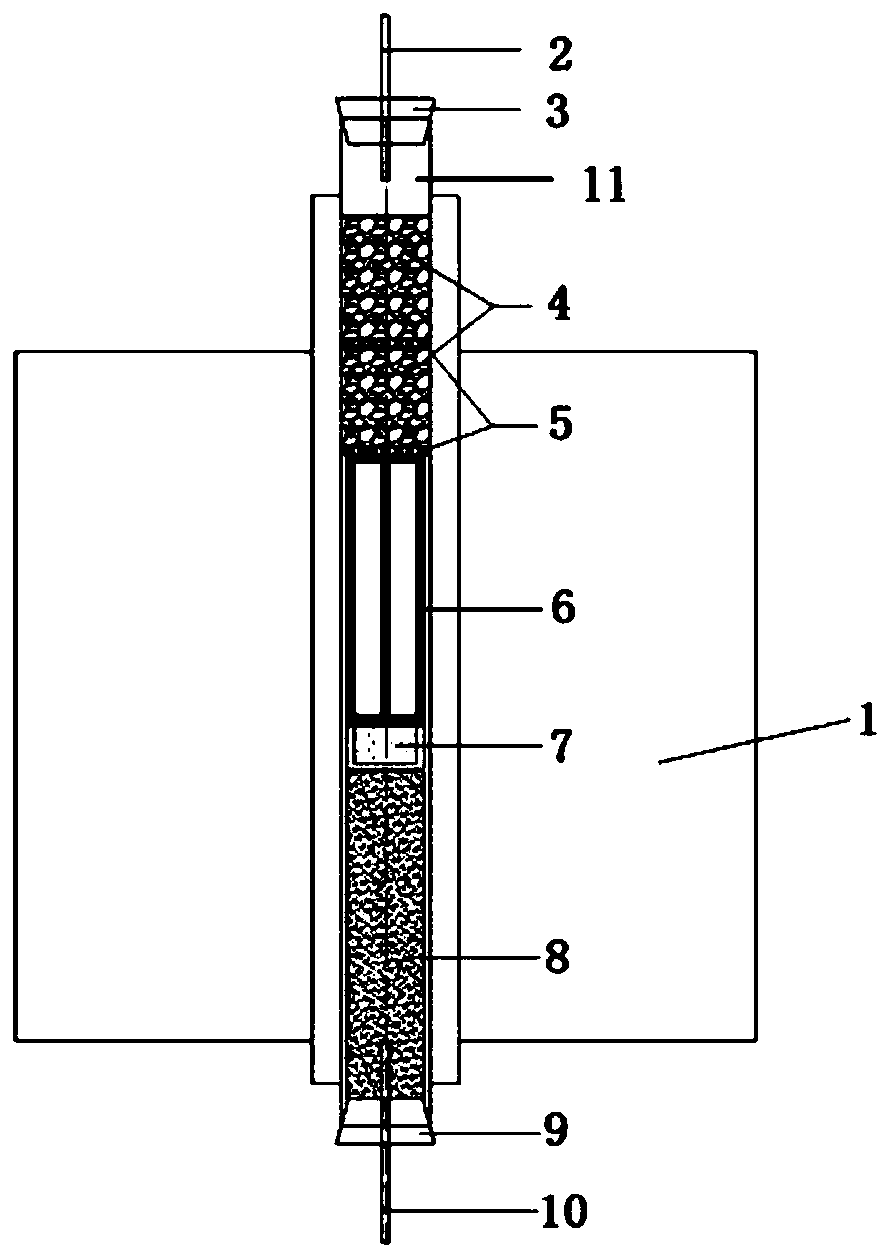

[0033] The invention discloses a device, method and application for simulating the enrichment form of zinc or alkali metal in the upper part of a blast furnace. Refer to the schematic diagram of the overall structure of the device figure 1 , including a high temperature resistance furnace 1, a transparent quartz reaction tube 11 detachably inserted in the high temperature resistance furnace 1, an upper sealing plug 3 with an air outlet 2 plugged on the top of the quartz reaction tube 11, and a lower sealing plug 3 with an air inlet 10 plugged at the bottom The sealing plug 9 and the quartz reaction tube 11 include furnace material 4 , iron-chromium-aluminum mesh interlayer 5 , high-temperature-resistant bracket 6 , zinc or alkali metal vapor generation source 7 and base 8 from top to bottom.

[0034] The experimental route of simulating the enrichment form of zinc or alkali metal in the upper part of the blast furnace by means of the above-mentioned device mainly includes thre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| freezing point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com