Elastic woven-like warp-knitted fabric with snagging prevention function and without spandex

A technology for anti-snag and knitted fabrics, which is applied in warp knitting, knitting, textiles and papermaking, etc. It can solve the problems of difficulty in achieving wear resistance, stiffness, and difficulty in improving the wearing performance of fabrics, and achieve the effect of tight fabric structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

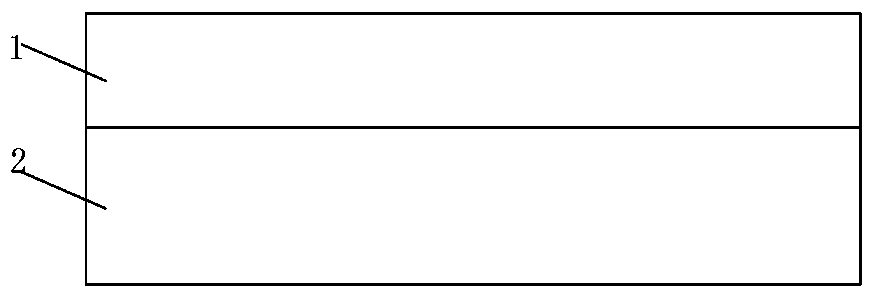

[0027] Embodiment one, as attached figure 2 with 3 As shown, a total of two bars GB1 and GB2 are used on the single-needle bed warp knitting machine to knit to form a fabric body. GB1 uses chemical fiber filaments, 2 closed needles warp flat weave structure, weaving to form a tight surface layer; GB2 uses non-spandex elastic chemical fiber filaments, reverse closed 3 needles warp velvet structure, weaves to form an elastic layer, so as to obtain a spandex-free fabric Elastic layer. Afterwards, the elastic layer is post-treated, such as evaporation, or other forms of shrinkage treatment, so that the elastic layer has a certain retraction effect. After sufficient retraction, the cloth surface of the tight surface layer will be more compact, and the GB1 chemical fiber filament will be tightened by it. , to achieve a good anti-snag effect, the fabric is woven with yarn and non-spandex elastic yarn raw materials (at least one non-spandex elastic yarn is used for weaving), has an...

Embodiment 2

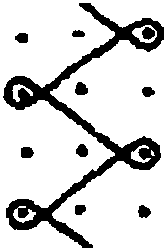

[0028] Embodiment two, as attached Figure 4 with 5 As shown, two bars GB1 and GB2 are used in total on the single-needle bed warp knitting machine to knit to form a fabric body. GB1 uses chemical fiber filaments with an open knitting chain structure to form a tight surface layer; GB2 uses non-spandex elastic chemical fiber filaments with a warp bias structure to form an elastic layer, thereby obtaining an elastic layer without spandex. Afterwards, the elastic layer is post-treated, such as evaporation, or other forms of shrinkage treatment, so that the elastic layer has a certain retraction effect. After sufficient retraction, the cloth surface of the tight surface layer will be more compact, and the GB1 chemical fiber filament will be tightened by it. , to achieve a good anti-snag effect, the fabric is woven with yarn and non-spandex elastic yarn raw materials (at least one non-spandex elastic yarn is used for weaving), has anti-snag, does not contain spandex and is elastic...

example 1

[0050] Item No.: T229396

[0051] Colour: Black

[0052] Model used: HKS4-1, 32GG, 130 inches

[0053] Padding digital: GB1: 1-0 / 1-2 / / ; GB2: 2-3 / 1-0 / /

[0054] Raw materials used: GB1: PET 75 / 72 SD DTY polyester; GB2: Elasterell-PET 50 / 36 SD FDY (T400)

[0055] Width: 180CM

[0056] Weight: 240GSM

[0057] Physical Test Parameters (Method-Snag-ASTM D3939-Snag-600 turn)

[0058] Length Rating: 4.5

[0059] Width Rating: 4.5

[0060] Physical test parameters (method-snag-BS8479-Snag-standard template-2000 rpm)

[0061] Length Rating: 4.5

[0062] Width Rating: 4.5

[0063] Physical Test Parameters (Method-Opening-LTD03- Effective Load -7.5lbf)

[0064] Length(hem%): 30%

[0065] Width (middle%): 50%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com