Load bearing, thermal insulation and decoration integrated building component, forming mold and manufacturing method thereof

A technology for building components and forming molds, applied in building structures, molds, buildings, etc., can solve the problems of easy falling off of thermal insulation materials and decorative panels, complicated operating procedures, short service life, etc. The effect of improving the firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

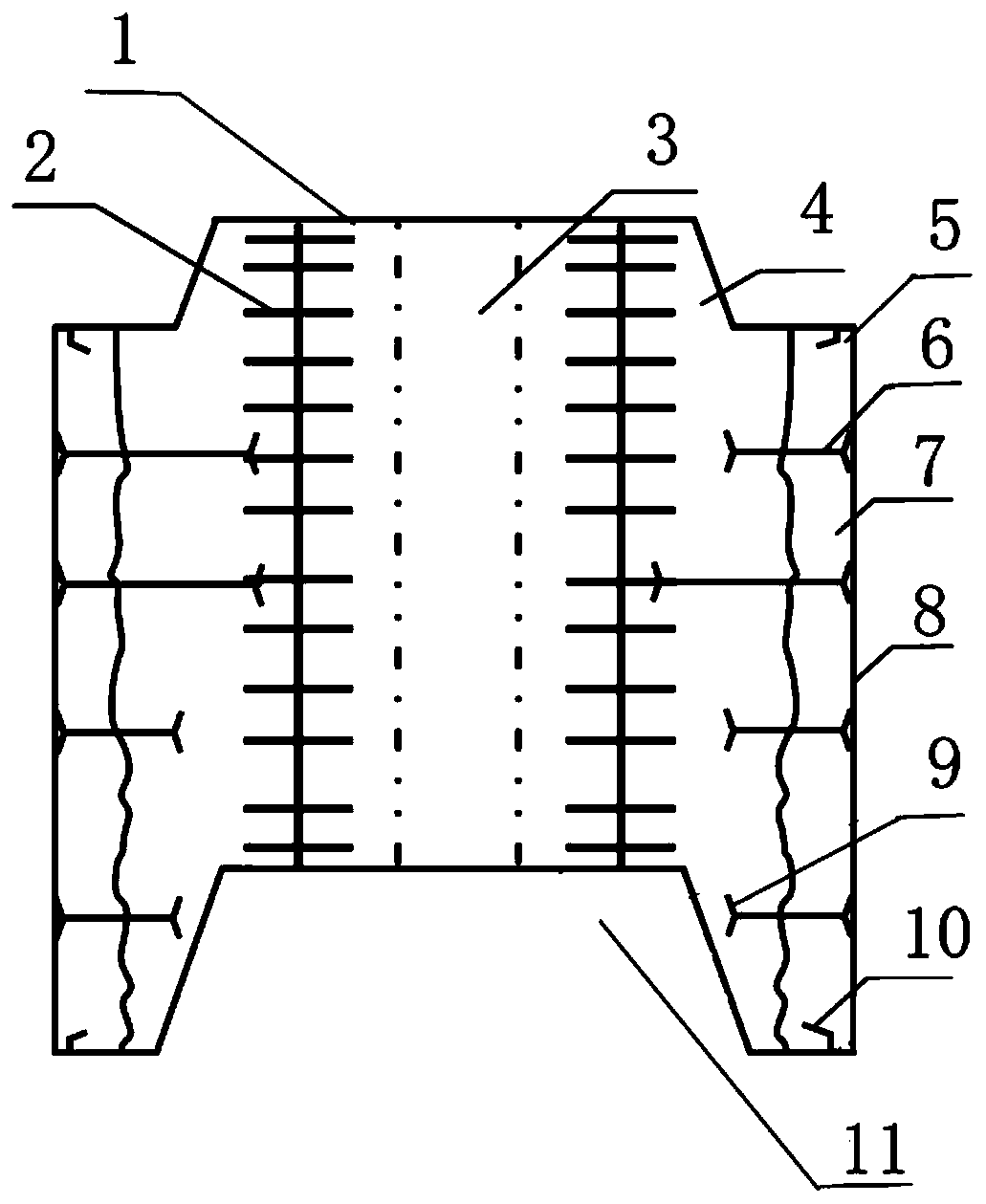

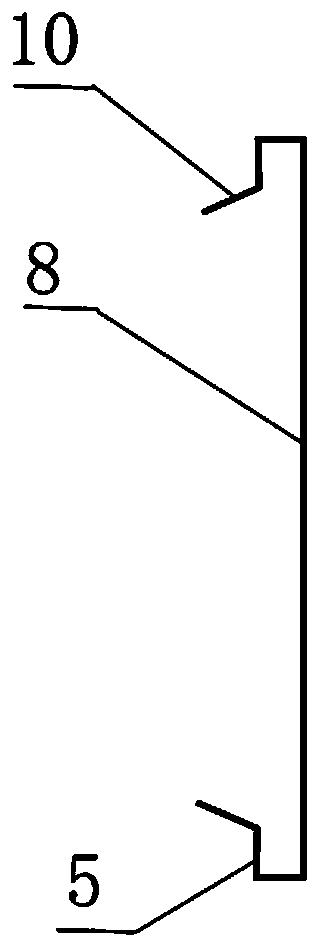

[0044] A load-bearing thermal insulation decoration integrated building component, such as figure 1 As shown, it includes a component body 1 and two decorative panels 8 located on the left and right sides of the component body. Such as image 3As shown, the upper and lower edges of the two decorative panels 8 are provided with hooks 5 bent towards the main body of the component, and the ends of the hooks 5 are obliquely provided with filling material drainage plates 10, and the extension surface of the filling material drainage plates 10 is 60° from the decorative panels degree angle. Decorative panel 8 is vertically placed with some connectors 6 with claws 9 at both ends near the component body side, and the claws at both ends of connectors can also be V-shaped (such as Figure 4 shown), arc (such as Figure 5 shown) or geometric hook shape (such as Image 6 shown). One end of the connecting piece 6 is bonded to the decorative panel 8 through the gelled thermal insulatio...

Embodiment 2

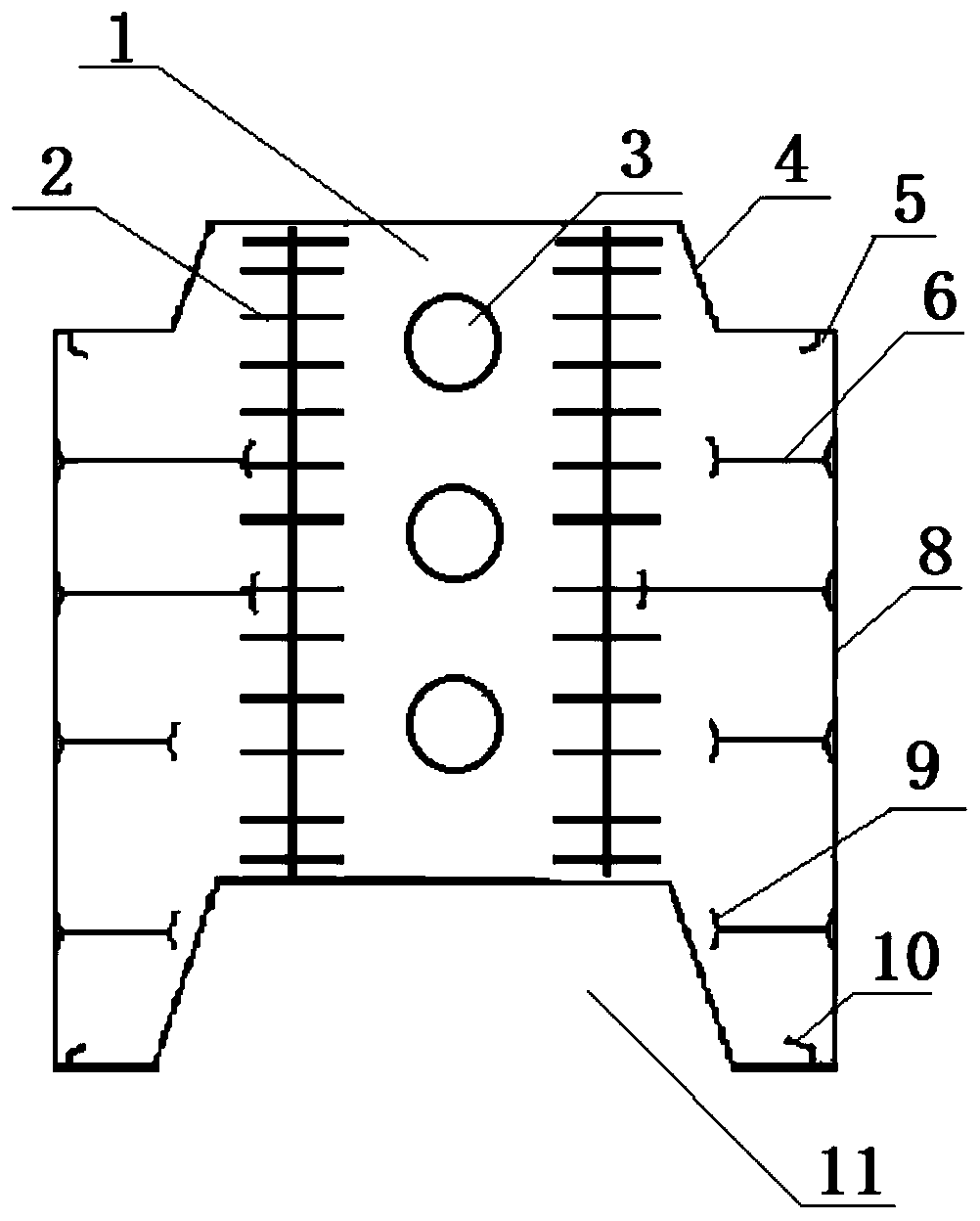

[0046] A load-bearing thermal insulation decoration integrated building component, such as figure 2 As shown, it includes a component body 1 and two decorative panels 8 located on the left and right sides of the component body. Such as image 3 As shown, the upper and lower edges of the two decorative panels 8 are provided with hooks 5 bent towards the main body of the component, and the ends of the hooks 5 are obliquely provided with filling material drainage plates 10, and the extension surface of the filling material drainage plates 10 is 60° from the decorative panels degree angle. Decorative panel 8 is vertically placed with some connectors 6 with claws 9 at both ends near the component body side, and the claws at both ends of connectors can also be V-shaped (such as Figure 4 shown), arc (such as Figure 5 shown) or geometric hook shape (such as Image 6 shown). One end of the connecting piece 6 is bonded to the decorative panel 8 , and the other end extends into t...

Embodiment 3

[0048] A forming mold for a load-bearing thermal insulation decoration integrated building component, such as Figure 7 As shown, it includes several mold baffles 12 arranged in parallel and spaced apart. The left and right sides of the mold baffle 12 are spaced with several positioning bars 18, which are detachably connected to the mold baffle, and the positions of the positioning bars are set according to the size of the processed component. The cross-section of the positioning bar may be trapezoidal, rectangular, triangular or circular. The position of the positioning bar on the opposite side of the adjacent mold baffle is corresponding, and the two ends of the mold head are provided with a positioning groove matching the shape of the positioning bar, and the mold head is inserted into the positioning bar through the positioning groove to realize the positioning and installation of the mold head. A second protrusion 16 is provided in the middle of the front side of the die...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com