Anti-blocking soot-blowing device for waste incinerating boiler cyclone separator

A cyclone separator and waste incineration technology, which is applied in the field of boiler soot blowing device, can solve the problem of high temperature of dust accumulation or coke hanging in the separator, and achieve the effect of preventing a large amount of dust accumulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and examples.

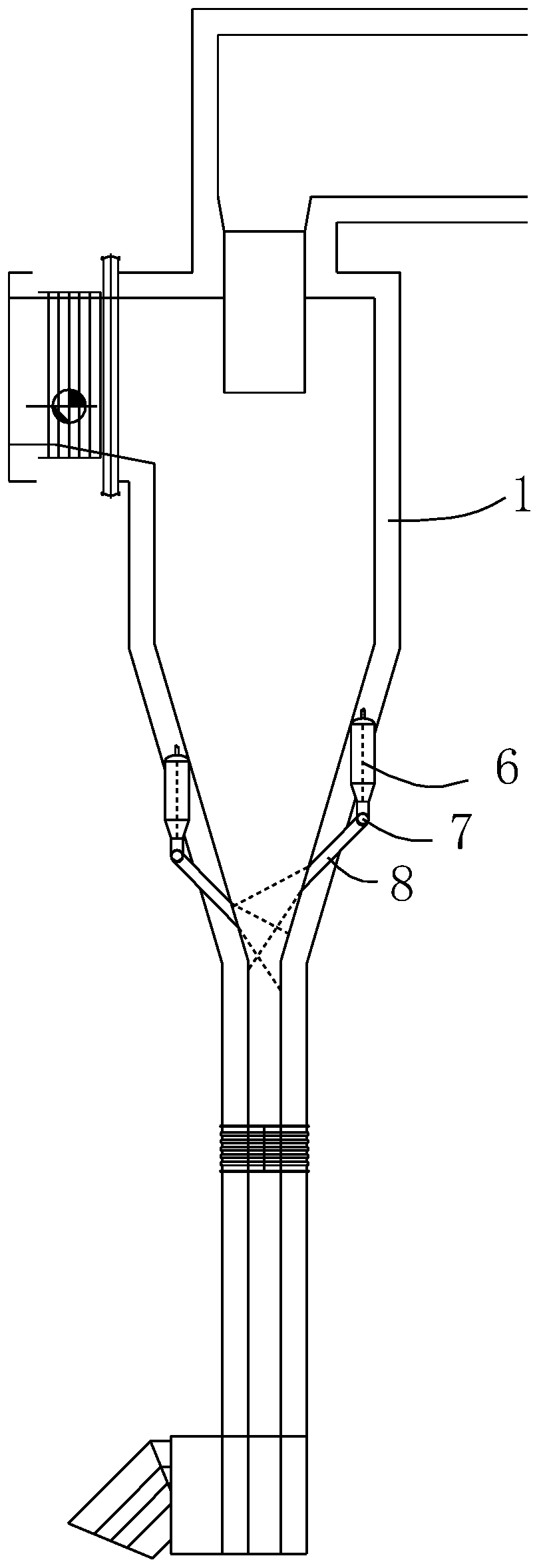

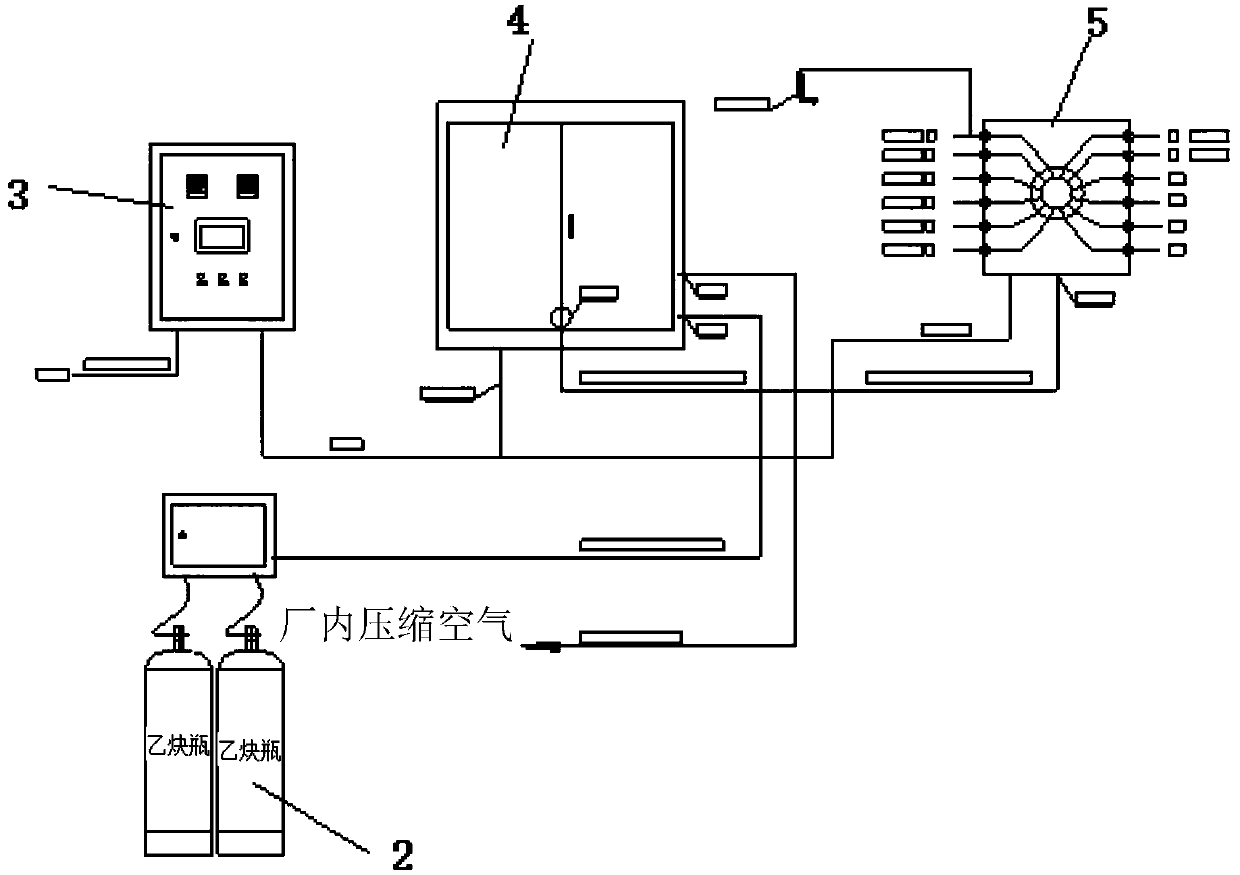

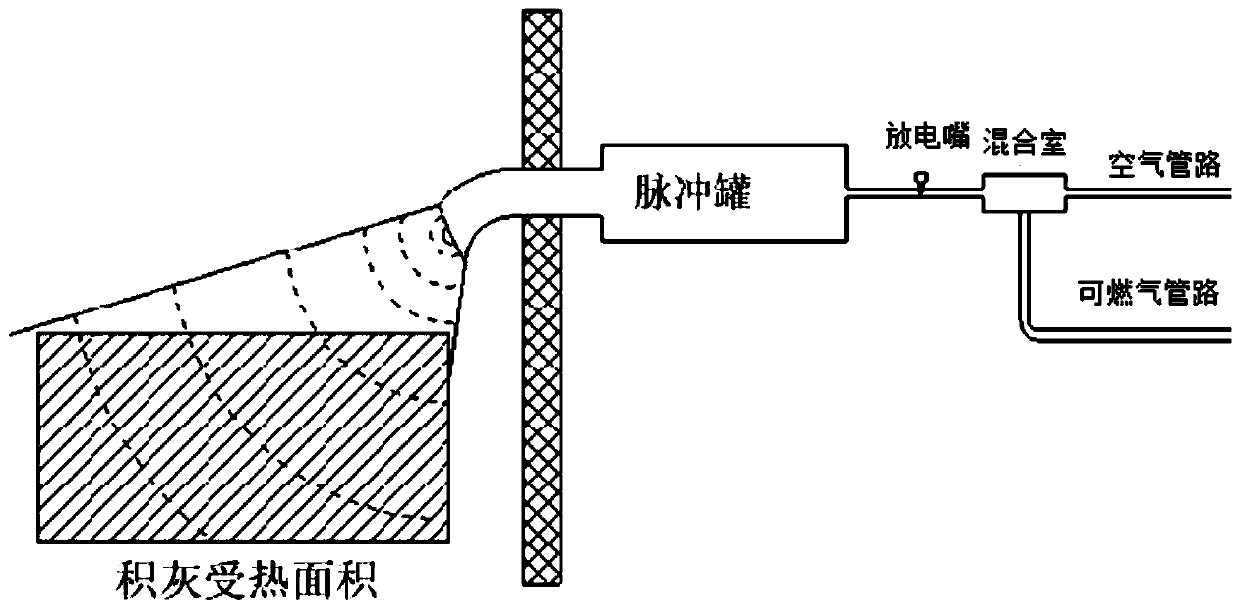

[0021] figure 1 , figure 2 , image 3 Among them, an anti-blocking soot blowing device for a cyclone separator of a waste incineration boiler, including a soot blower, at least one set of soot blowers, preferably two to eight sets, and the best of both, the soot blower is connected to the waste incineration boiler cyclone On the separator; the soot blower includes the gas source part, flow regulating cabinet, gas guiding ignition cabinet, control cabinet, pulse tank and soot blowing pipe, one end of the soot blowing pipe is connected to the pulse tank, and the other end passes through the outer wall of the separator and enters the inner Cavity, the output end of the gas-guiding ignition cabinet is connected with the pulse tank, the inlet end of the gas-guiding ignition cabinet is connected with the flow regulating cabinet, and the signal end of the cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com