Construction Technology of Modular Plumbing Floor

A construction technology and modular technology, applied in hot water central heating system, heating method, lighting and heating equipment, etc., can solve the problems of prolonging the construction period, achieve the effect of improving construction efficiency, shortening construction period, and easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

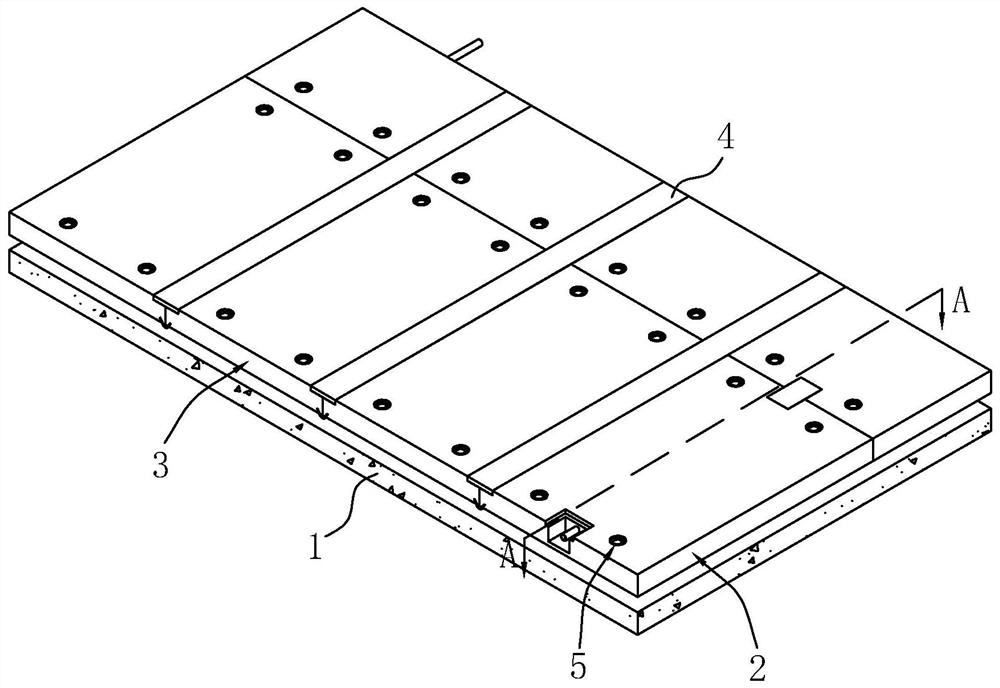

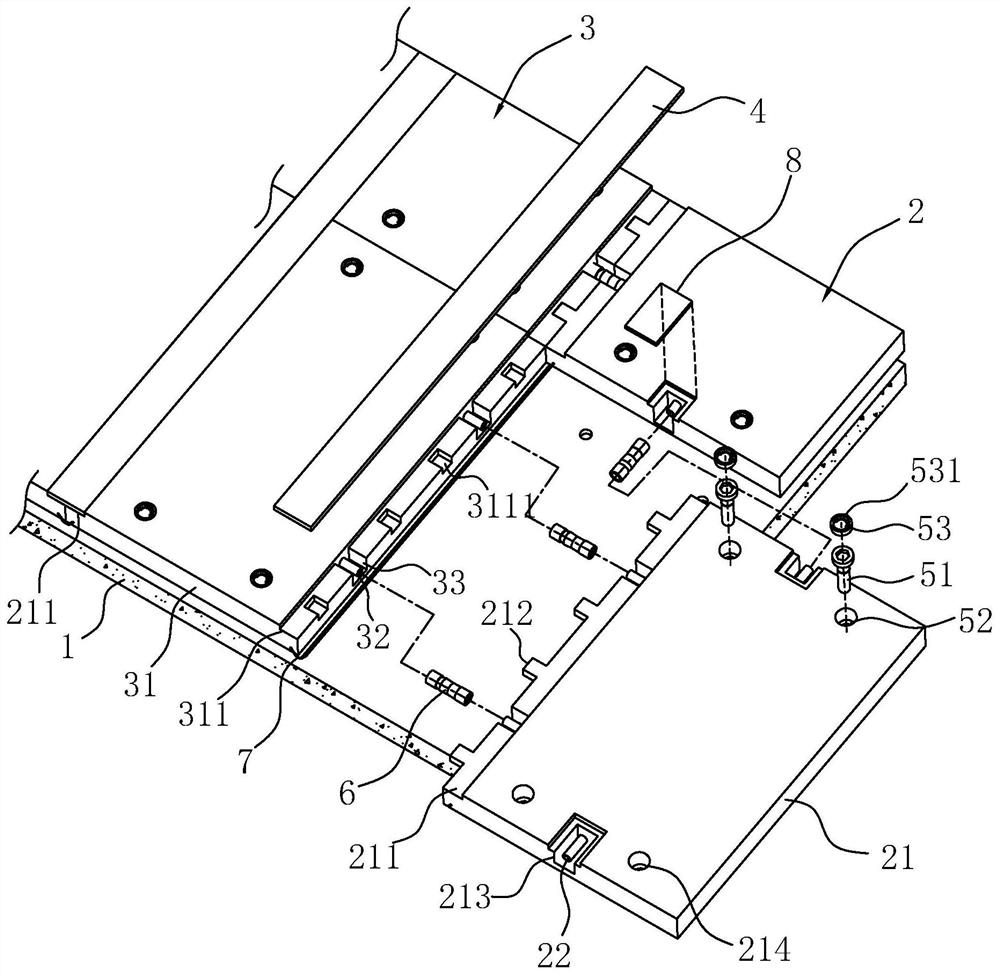

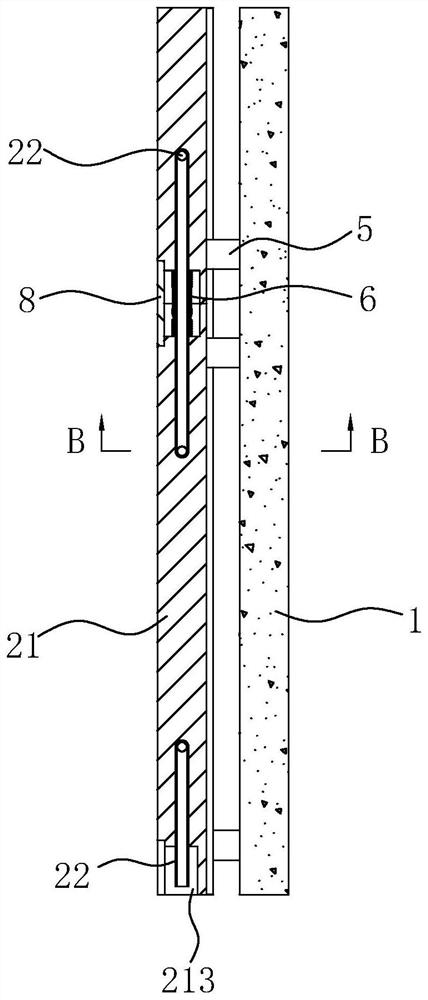

[0045] Example: A modular plumbing floor structure such as figure 1 and figure 2 As shown, it includes the first floor 2 and the second floor 3 that are spliced and laid on the floor 1. The first floor 2 includes a first board 21 and a first water pipe 22 fixedly embedded in the first board 21. The second floor 3 includes the second plate body 31 and the second water pipe 32 fixedly buried in the second plate body 31, the first water pipe 22 in the first plate body 21 and the second water pipe 32 in the second plate body 31 are adjacent to each other The first water pipes 21 in each first plate body 21 are connected by connecting pipes 6, the bottom of the seam between the first plate body 21 and the second plate body 31, and the two adjacent second plate bodies 31 are located at the water pipe connection. A waterproof belt 7 is installed at the bottom of the seam at the bottom of the seam, the top of the seam between the first board 21 and the second board 31, and the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com