Micro-seismic sensor taking and placing device with strain gauge bonding structure and using method thereof

A technology of microseismic sensors and pick-and-place devices, which is applied in the direction of measuring devices, seismic signal receivers, instruments, etc., can solve the problems of extended construction period, time-consuming and labor-intensive installation process, high economic cost, etc., and achieve the effect of reducing economic cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with accompanying drawing:

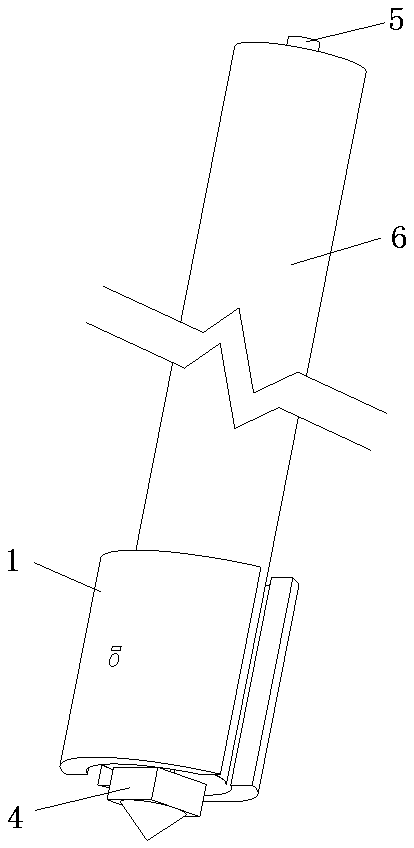

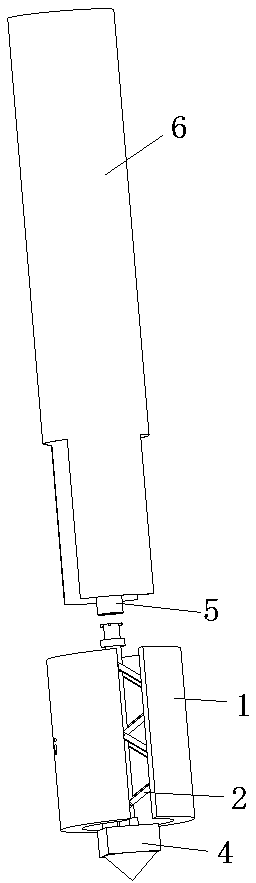

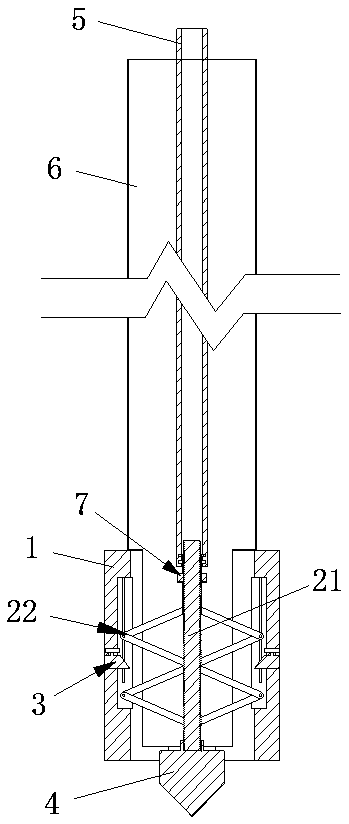

[0050] Such as figure 1 , figure 2 , image 3 The shown pick-and-place device for microseismic sensors with a strain gauge pasting structure includes a support wall assembly with a hollow columnar structure as a whole. The support wall assembly is formed by combining two symmetrically arranged arc-shaped plates 1 with the same structure. Such as Figure 8 , Figure 9 As shown, the inner walls of the two arc-shaped plates 1 are respectively provided with square grooves 12 inwardly, and the groove walls on both sides of the groove 12 are symmetrically provided with slide bar grooves 13, and the grooves 12 are also provided with connecting two grooves. The fixed rod 14 of the side groove wall, the fixed rod 14 is arranged on the side close to the microseismic sensor 4, the setting direction of the groove 12 and the slide rod groove 13 coincides with the axial direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com