Cutter wear state recognition and prediction method based on hidden Markov model

A hidden Markov, tool wear technology, applied in character and pattern recognition, prediction, calculation model and other directions, can solve problems such as practical application difficulties, implementation efficiency and accuracy need to be improved, and achieve high accuracy and improve accuracy. , the recognition effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

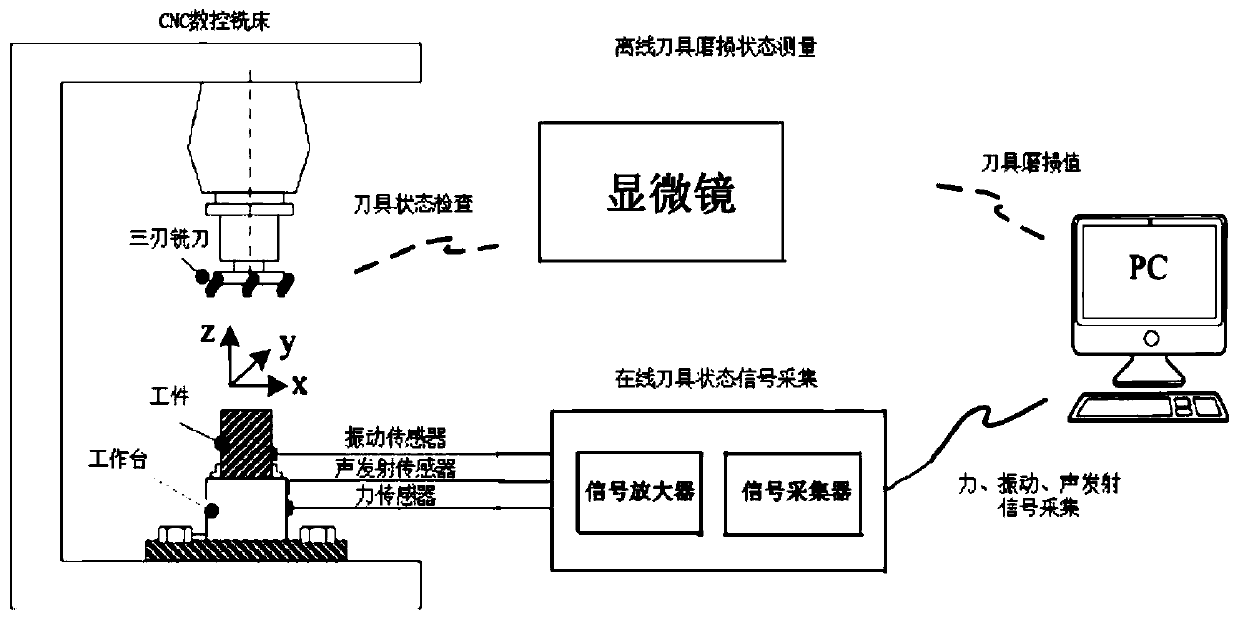

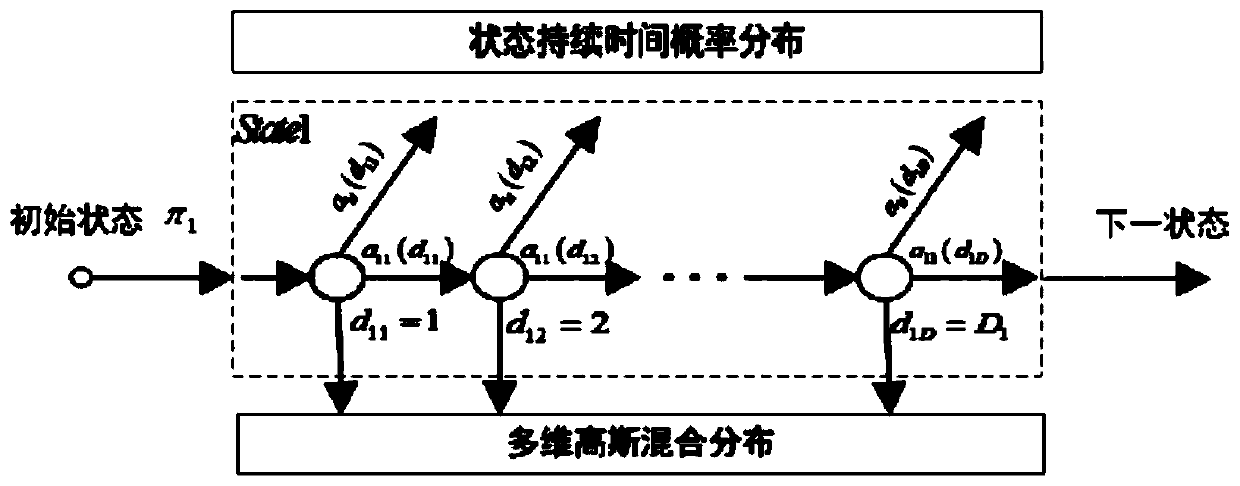

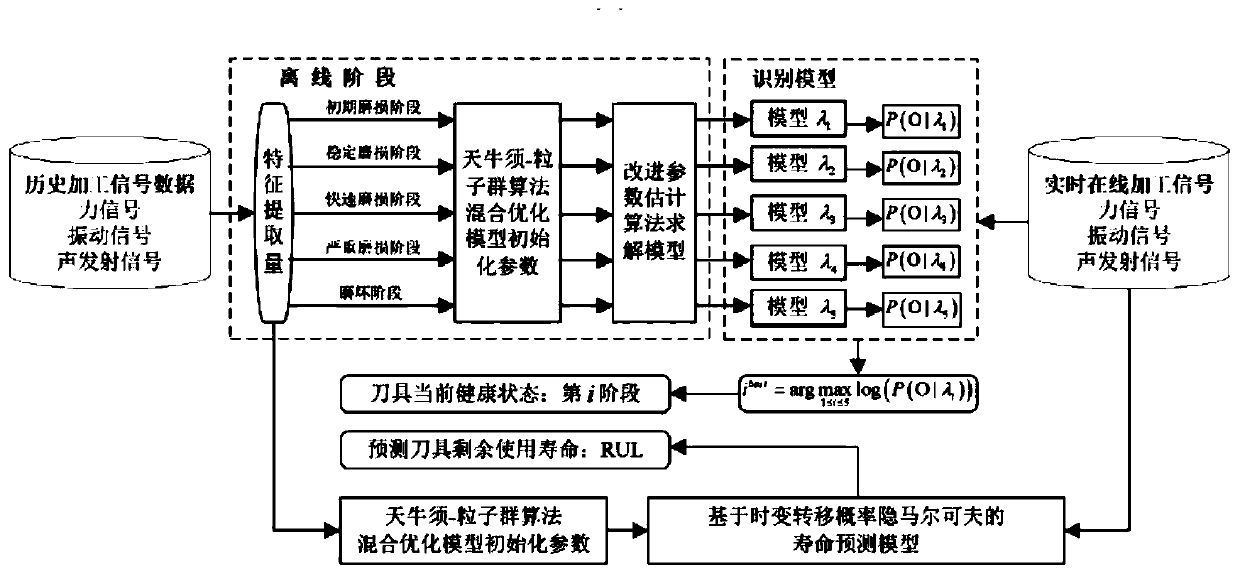

[0046]The present invention discloses a tool wear state identification and prediction method based on a hidden Markov model, which is mainly based on the learning and modeling of the response signal data of the tool processing process based on the extended optimization hidden Markov model, learning the tool wear degradation mode, and It is applied to the online real-time identification and prediction system of tool wear status. The extended hidden Markov model refers to introducing the time component into the state transition probability matrix of the traditional hidden Markov model, and the state transition matrix corresponds to the current state duration respectively. At the same time, considering th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com