Plasma jet velocity monitoring method and device

A plasma and jet velocity technology, applied in the field of plasma jet, can solve the problems of high construction cost of system equipment, complex plasma jet velocity measurement process, etc., to reduce construction cost, improve calculation accuracy and accurate confirmation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

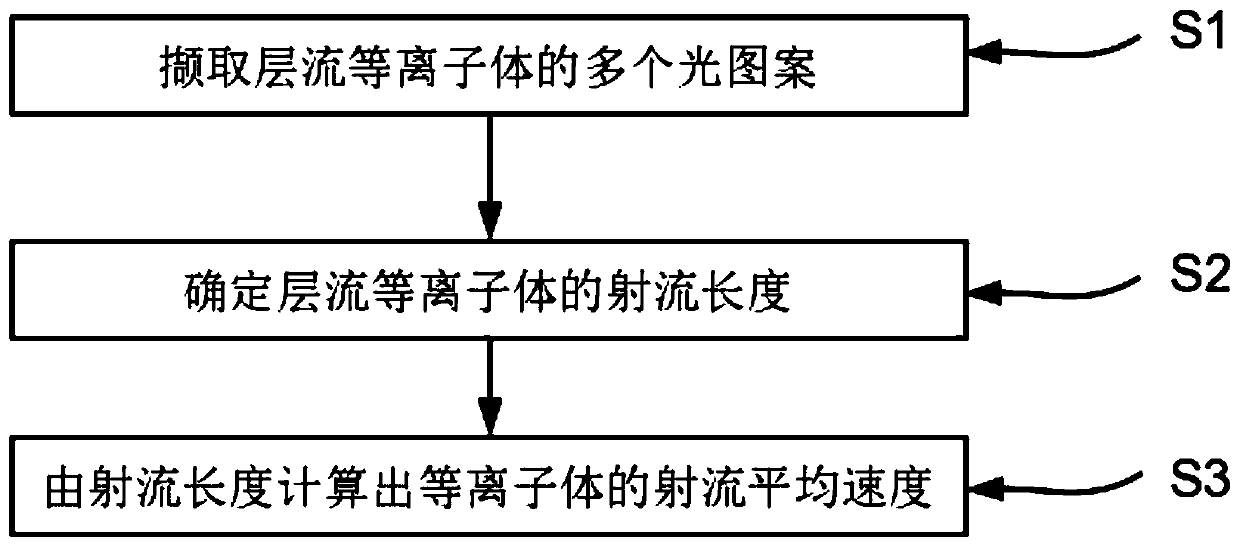

[0046] refer to figure 1 , a method for monitoring plasma jet velocity disclosed in an embodiment of the present invention, comprising:

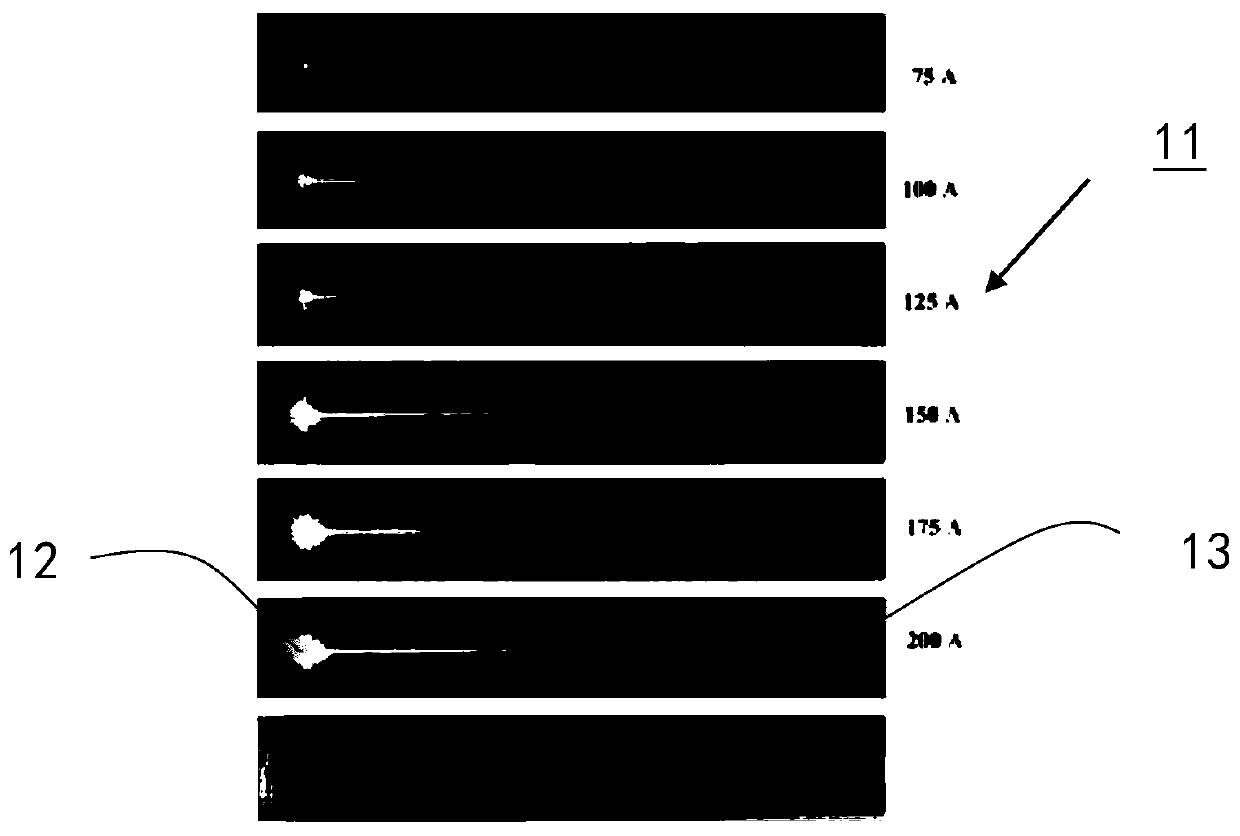

[0047] Step S1: extract a plurality of light patterns of laminar flow plasma, and determine the jet boundary of the plasma jet from the light-emitting boundary of the light pattern based on the positive correlation between the output power and the concentration of the plasma;

[0048] Step S2: determining the jet length of the laminar plasma jet based on the axial jet boundary of the plasma jet from the jet exit to the jet end; and,

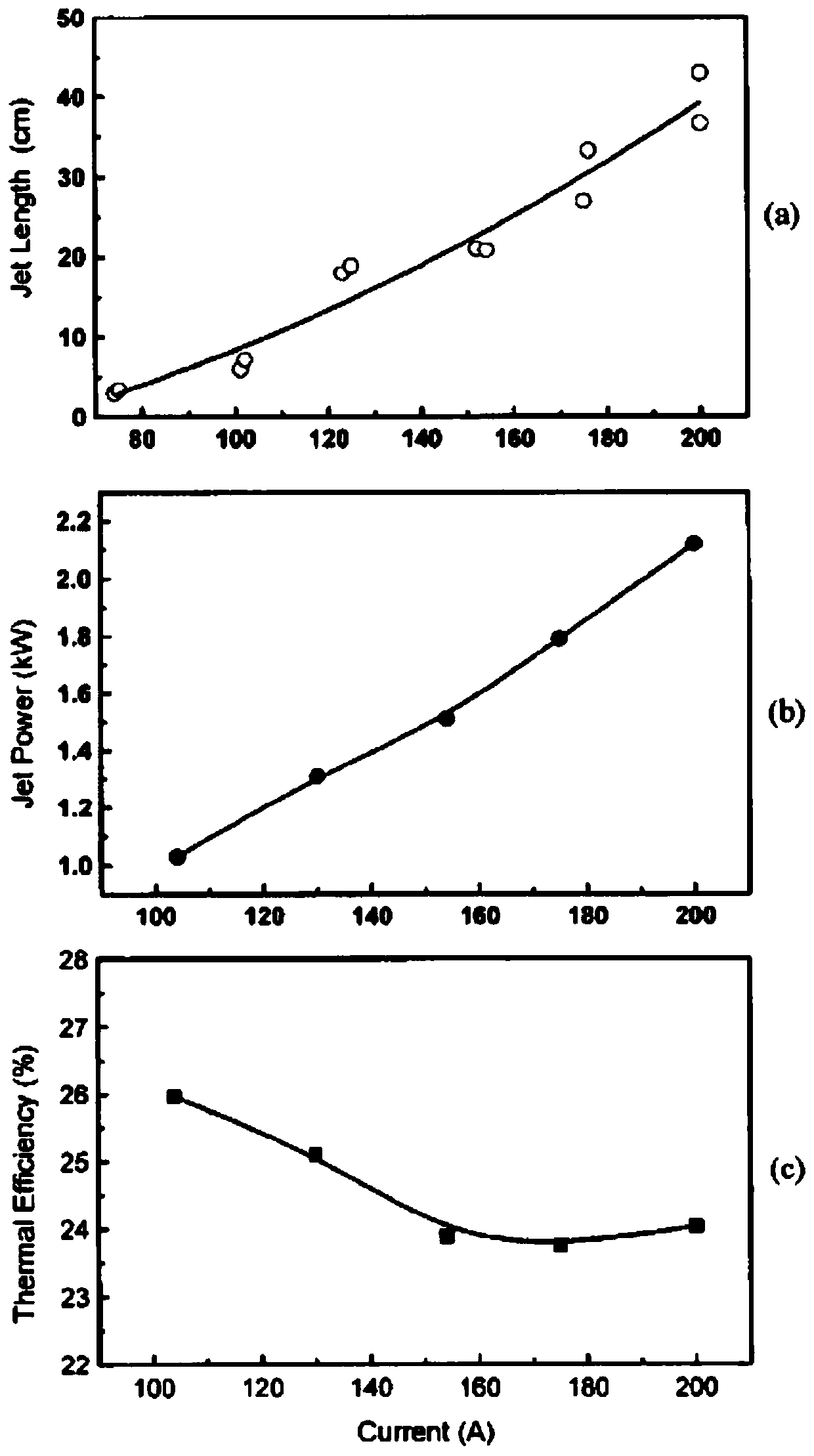

[0049] Step S3: calculating the average jet velocity of the plasma from the jet length of the laminar plasma, including: establishing the relationship between the jet length of the laminar plasma and the arc current under the predetermined different arc current jet velocity. .

[0050] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com