PLC control cabinet with high dustproof property

A control cabinet, dust-proof technology, applied in the direction of casing/cabinet/drawer parts, electrical equipment casing/cabinet/drawer, electrical components, etc., can solve the problem of poor sealing of rubber strips and lack of dustproofness , Dustproof effect is not good and other problems, to achieve good self-cleaning, anti-twisting force, high dustproof effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

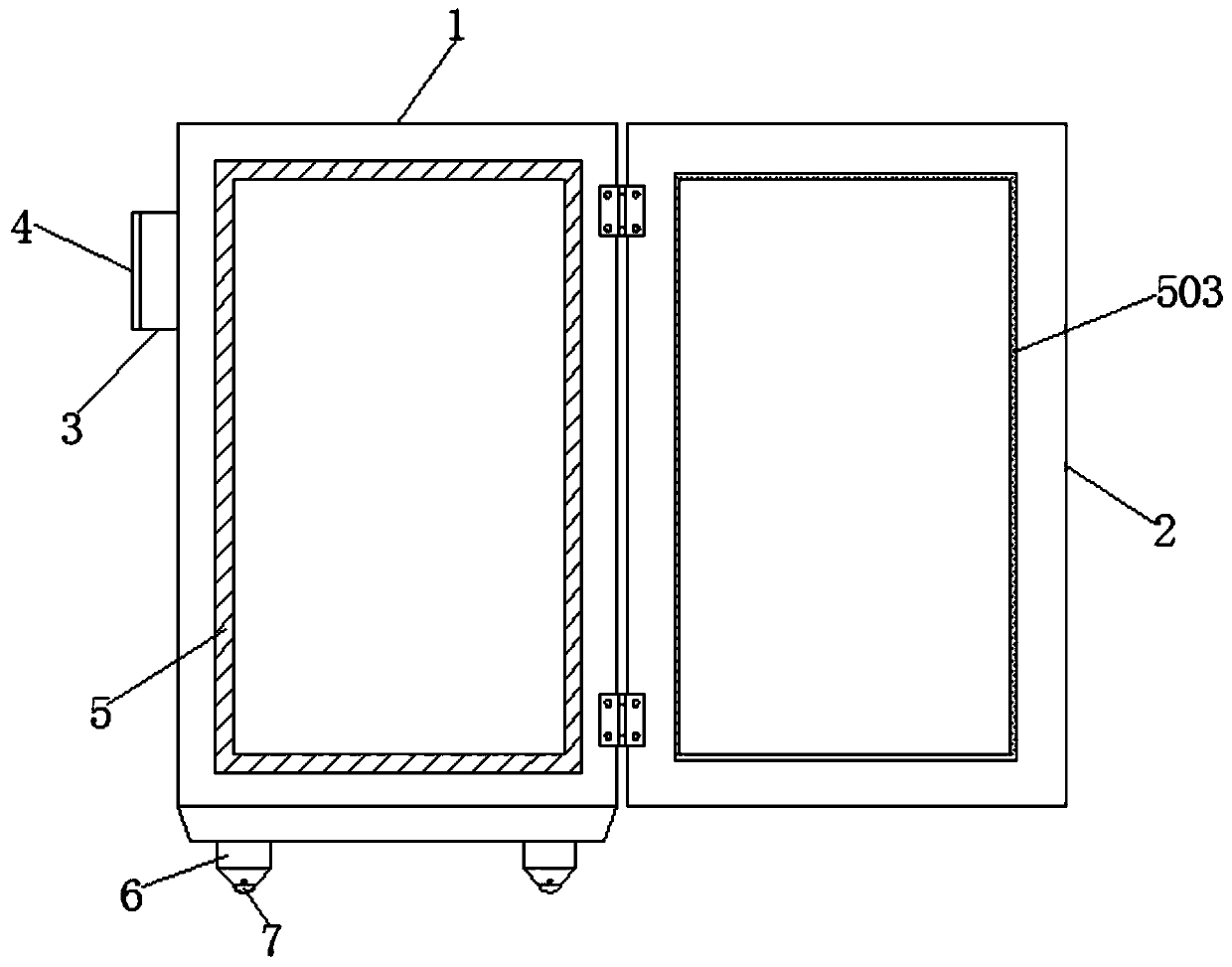

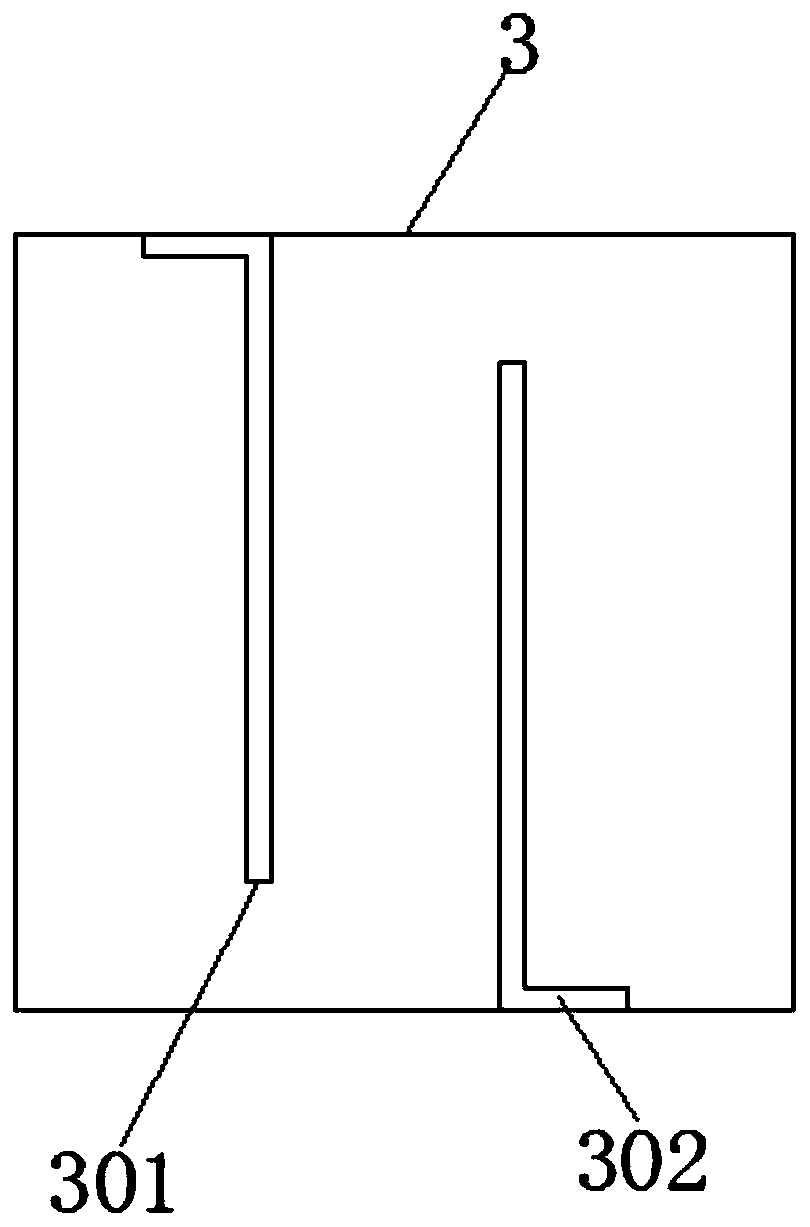

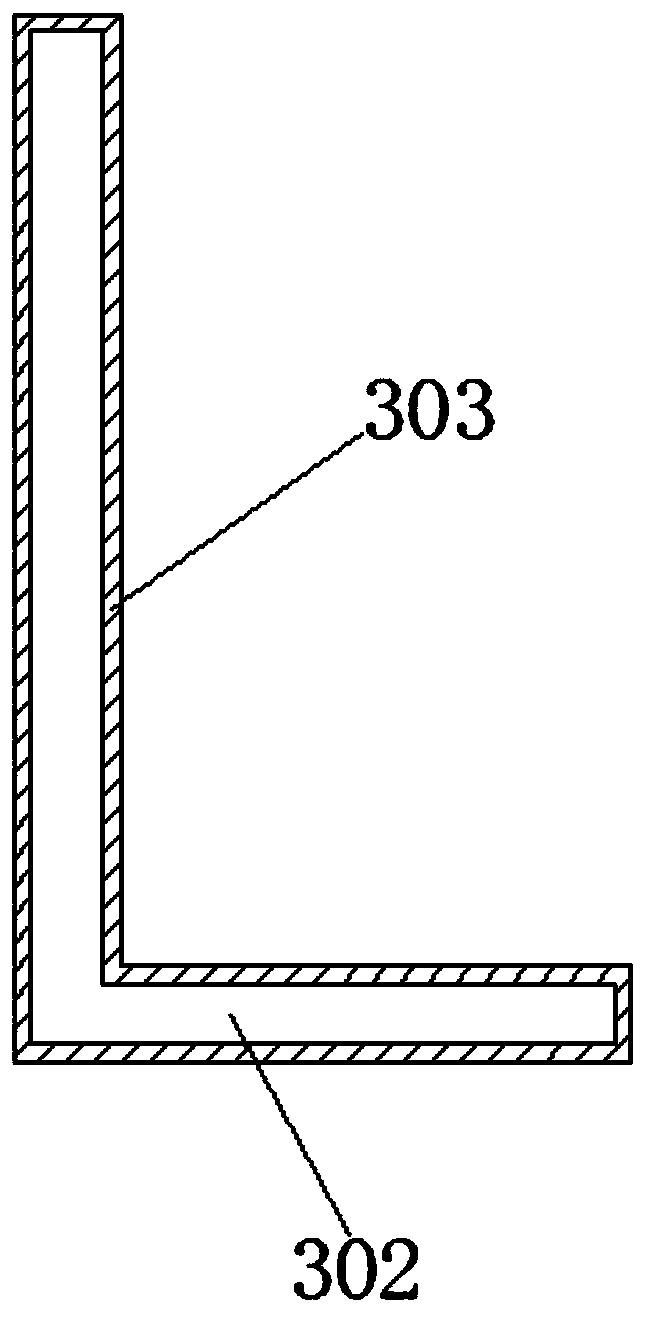

[0024] Such as Figure 1-6 As shown, the present invention provides a technical solution: a high dust-proof PLC control cabinet, including a cabinet body 1 and a cabinet door 2, one side of the cabinet body 1 is connected with a cabinet door 2 through a hinge, and the cabinet body 1. A metal frame 3 is symmetrically welded on the outer walls of both sides, and a No. 1 L-shaped partition 301 is welded in the inner cavity of the metal frame 3. A No. 2 L-shaped partition 302 is welded on one side of the No. 1 L-shaped partition 301 . The surfaces of No. 1 L-shaped partition 301 and No. 2 L-shaped partition 302 are coated with fluorocarbon coating 303, and one end of the metal frame 3 is symmetrically provided with concave holes 304, and one side of the metal frame 3 is detachably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com