Architecture for silicon photonics enabling wafer probe and test

A photonic and wafer technology, used in optical components, semiconductor/solid-state device testing/measurement, instruments, etc., can solve the problems of difficult to test optical components of photonic chips, and impossible to test optical components of photonic chips.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

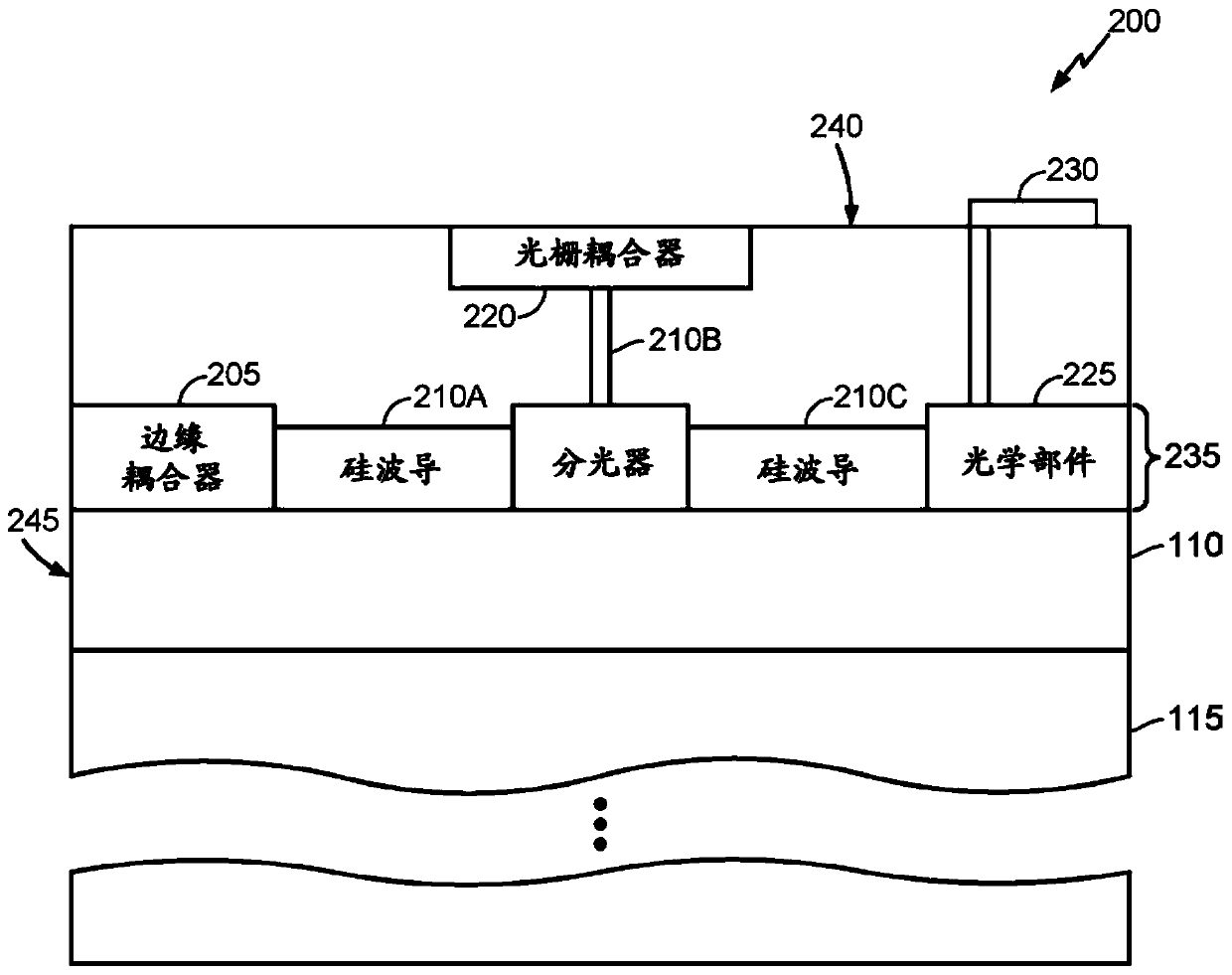

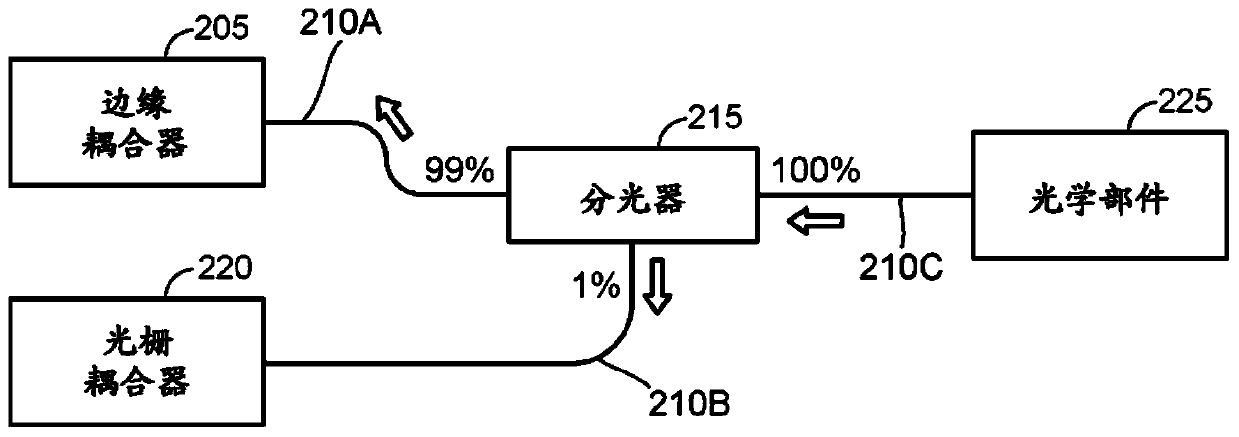

[0036] Various features are described below with reference to the accompanying drawings. It should be noted that the drawings may or may not be drawn to scale and that elements of like structure or function are represented by like reference numerals throughout the drawings. It should be noted that the drawings are only intended to facilitate the description of features. They are not intended as an exhaustive description of the specification or as a limitation on the scope of the claims. Additionally, the illustrated examples do not necessarily have all of the aspects or advantages shown. An aspect or advantage described in connection with a particular example is not necessarily limited to that example, and can be practiced in any other example even if not so shown or explicitly described.

[0037] Embodiments herein describe techniques for using grating couplers to test or align optical components in photonic chips. In one embodiment, the photonic chip may include edge coup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com