Solid-state solar paint

A coating layer, conductive coating technology, applied in the field of solid-state solar coatings, to achieve the effect of reducing capital expenditure requirements, small manufacturing and transportation costs, and reducing import and export taxes or duties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

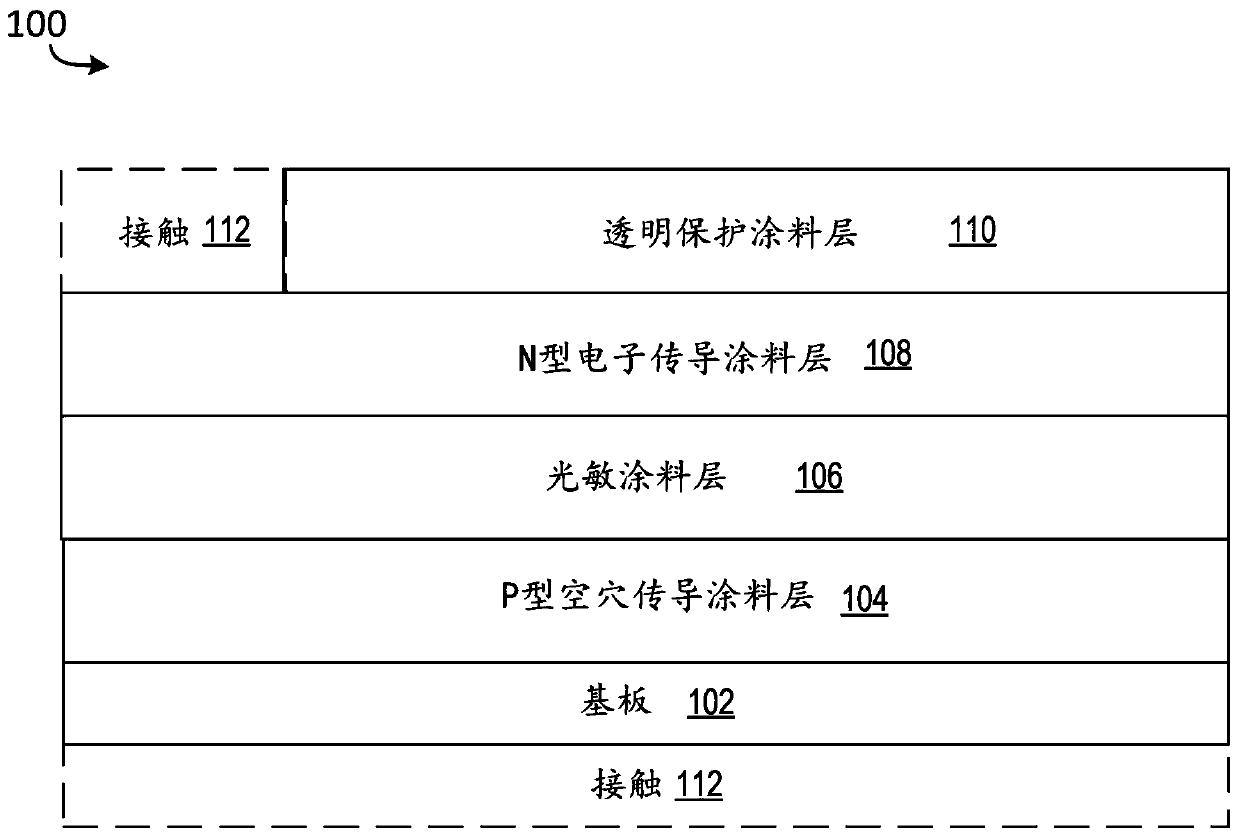

[0027] overview

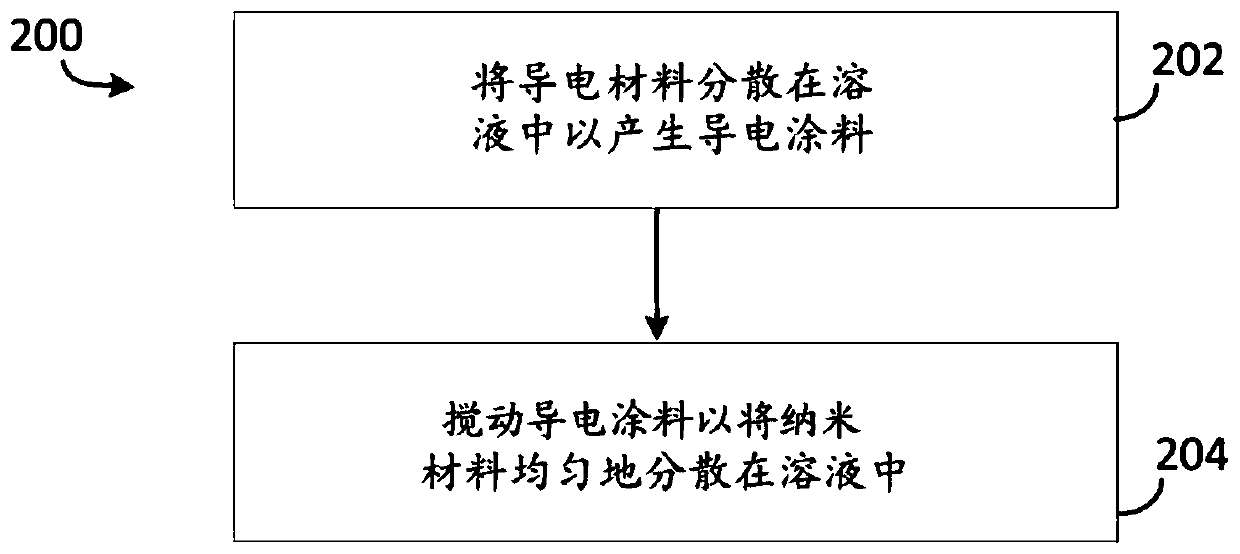

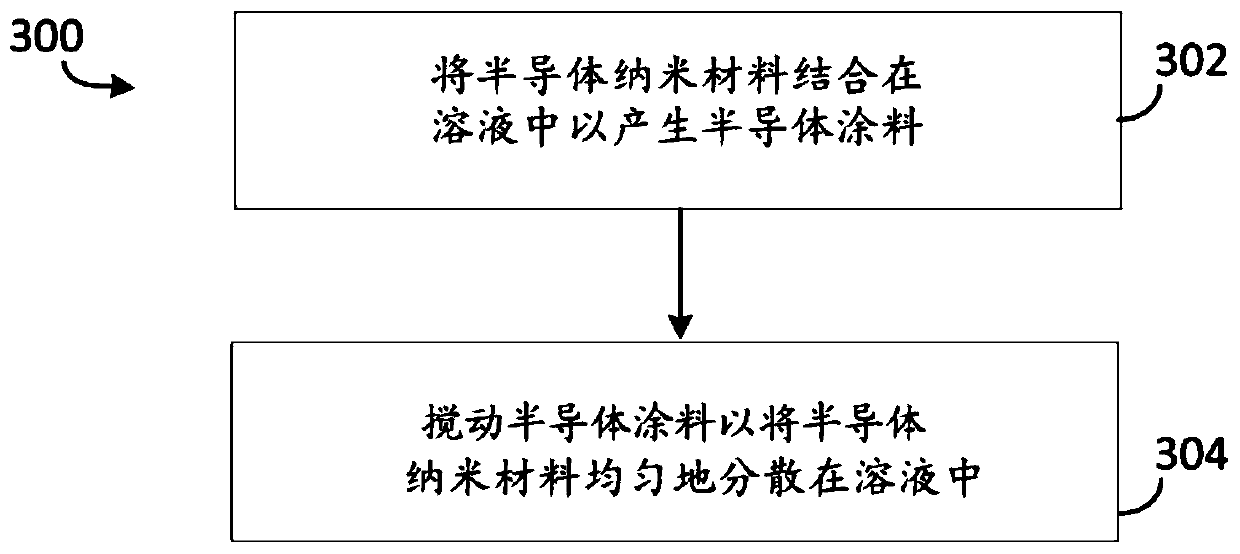

[0028] Devices, systems and methods for producing solar paint and solar paint circuits are described below. Paint circuits (eg, solar paint circuits) are created by applying conductive paint (eg, solar paint circuits) layer by layer to the surface of a substrate. The substrate can be, for example, a piece of wood, brick, stucco, stone, metal surface, or other surface to which a paint can be applied. The solar paint layer can be manually applied to the substrate using an aerosol dispenser or other aerosolized spray tool.

[0029] Although the terms "solar paint circuit" and "solar paint" are used in the context of describing particular embodiments of the inventive subject matter, this is not meant to be limiting. Other paint circuits that do not incorporate solar energy (such as batteries, LEDs, antennas, or other circuit elements) can be implemented, as well as paint layers that do not directly participate in forming a solar-incorporating circuit.

[003...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com