Environment-friendly product forming hydraulic press

A technology for hydraulic presses and products, applied in the field of environmental protection product forming hydraulic presses, can solve the problems of low productivity, deformation, low automation level, etc., and achieve the effect of stable and reliable pressing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

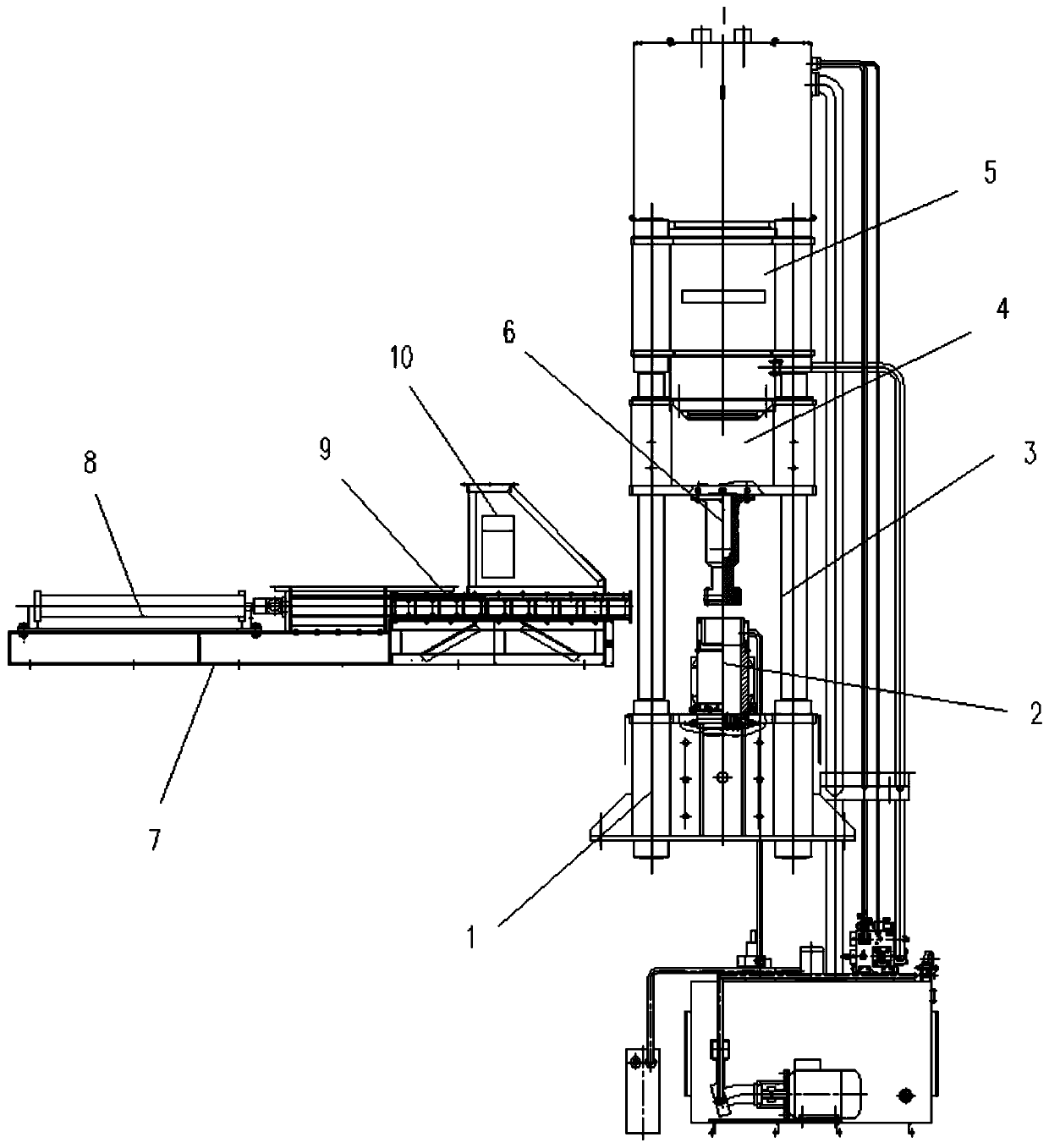

[0013] A hydraulic press for forming environmentally friendly products, which includes a main frame 1, a feeding device, a pressing cylinder 5, a pressing plunger 6 and a material cylinder 2, the pressing cylinder is fixedly installed on the top of the main frame, and two A guide post 3, on which a slide block 4 is installed, the lower end of the piston rod of the pressing cylinder is fixedly connected with the top of the slide block, the press plunger is fixedly connected with the bottom of the slide block, and the guide post plays a role of supporting and guiding, pressing When the piston rod of the material cylinder is stretched, the pressure material plunger is moved up and down along the vertical direction, and the action is relatively stable and reliable.

[0014] The material cylinder is fixedly installed on the lower part of the main frame and the top opening is facing the pressing plunger. The feeding device includes a feeding frame 7, a feeding cylinder 8 fixedly inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com