Lightweight rear suspension structure applied to electric automobiles

An electric vehicle, lightweight technology, applied in the direction of suspension, elastic suspension, vehicle spring, etc., can solve the problems of large unsprung mass, small specific stiffness, poor ride comfort and ride comfort, etc., to reduce self-weight , Linear stiffness change, the effect of improving ride comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

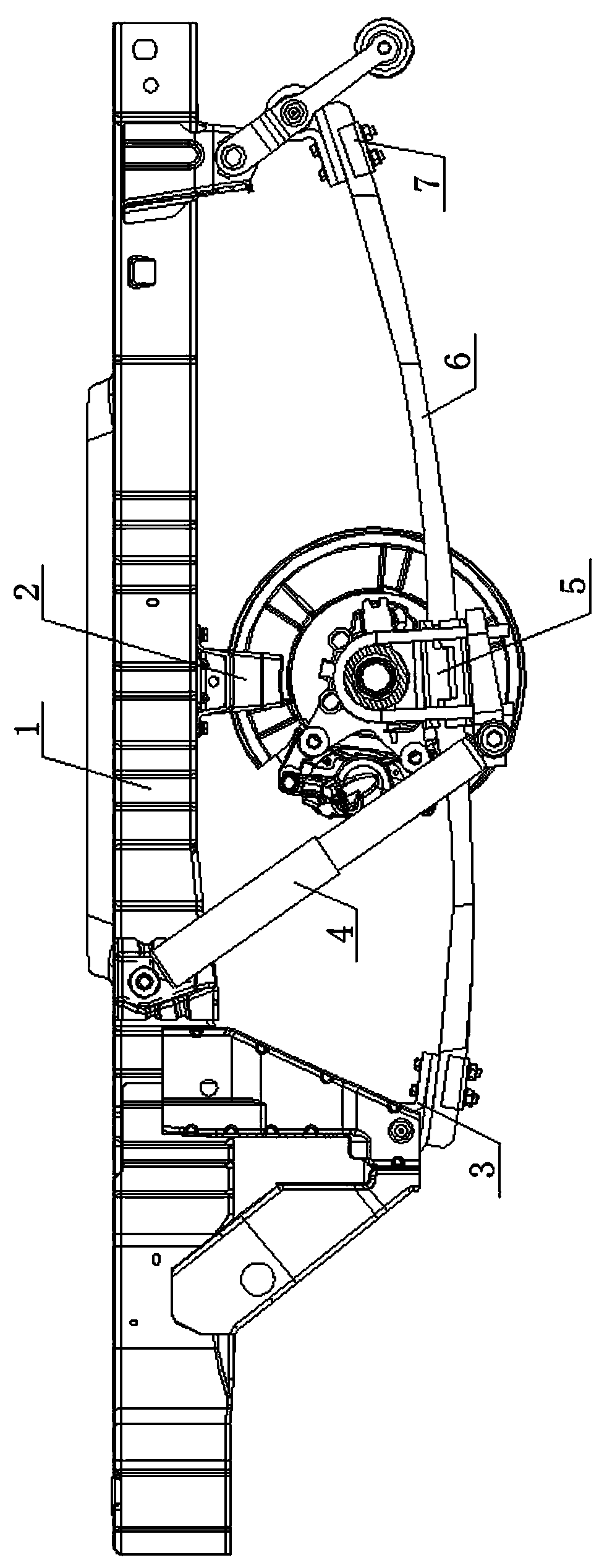

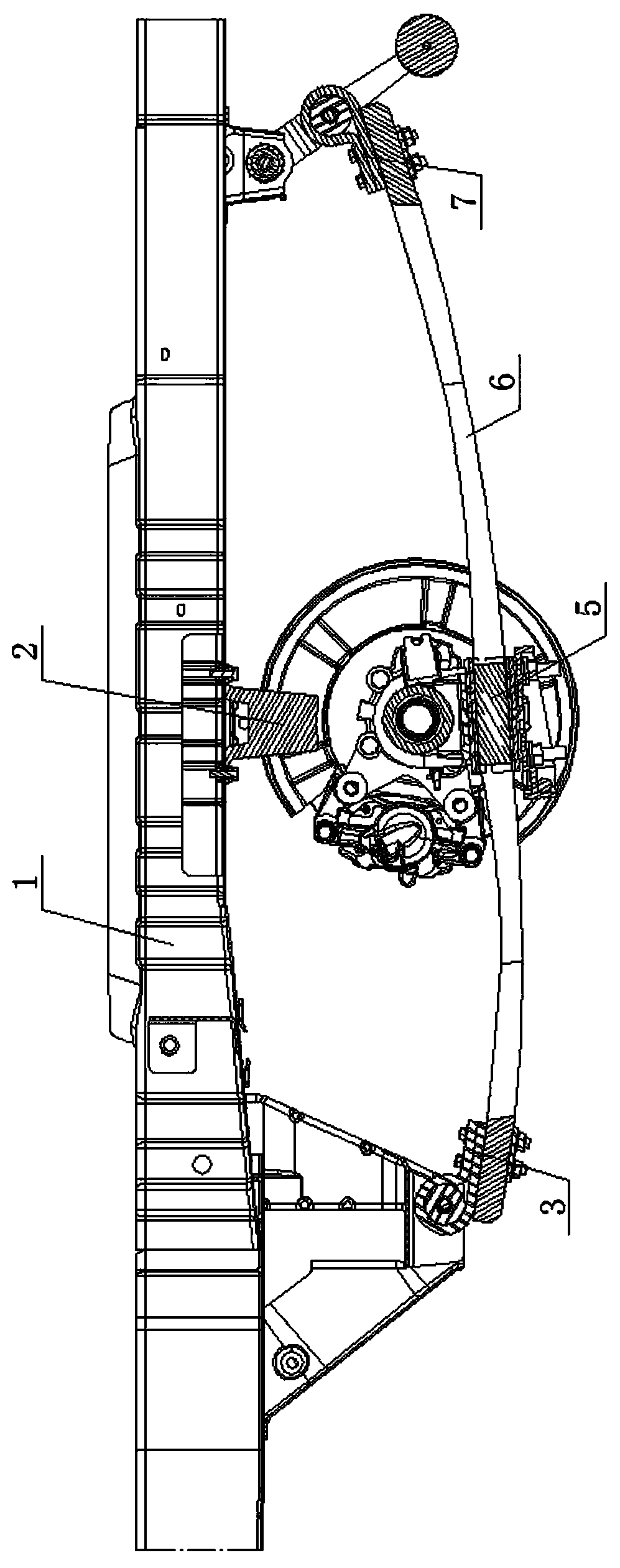

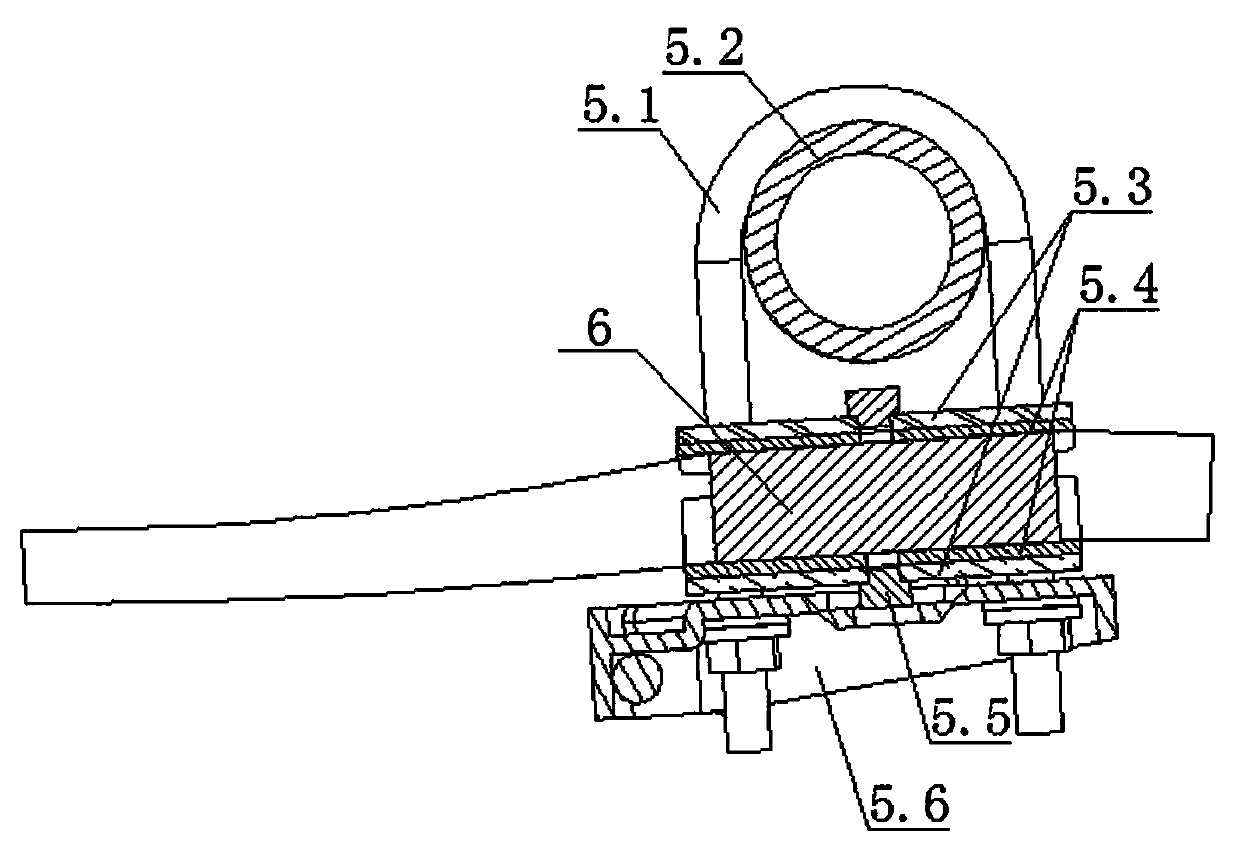

[0028] like Figure 1 to Figure 5 As shown, the present invention includes a single leaf spring 6 made of composite material, the front end 3 of the single leaf spring 6 is connected with a front ear 3.3, and the rear end 7 of the single leaf spring 6 is connected with a rear ear 7.2, The middle part 5 of the single leaf spring is located in the leaf spring seat 5.3 of the rear axle, and the middle part 5 of the single leaf spring is equipped with a backing plate frame 5.6 and two U-shaped bolts 5.1, and the two U-shaped bolts 5.1 are connected to the backing plate frame by nuts 5.6, the backing plate frame 5.6 is close to the bottom of the rear axle leaf spring seat 5.3 and the backing plate frame 5.3, the single leaf spring 6 and the rear axle leaf spring seat 5.3 are fixedly connected by the rivet head 5.5, and the backing plate frame 5.6 A shock absorber 4 is hinged on the top, and the upper end of the shock absorber 4 is used to be connected to the longitudinal beam 1 of ...

specific Embodiment 2

[0034] like Image 6 and Figure 7 , as shown, the difference from the specific embodiment 1 is that the front end 3 of the single-leaf leaf spring 6 and the rear end 7 of the single-leaf leaf spring 6 have different structural forms to match the use of the vehicle body longitudinal beam 1 of the vehicle body mounting points of different widths, The front roll ear includes a front U-shaped roll ear body 3.8, and the front end 3 of the single leaf spring 6 extends into the front U-shaped roll ear body 3.8 and the front U-shaped roll ear body 3.8 is fixedly connected to the single piece by fastening bolts 3.7. The front end portion 3 of the leaf spring 6 is embedded with a front leaf spring rubber bushing 3.6 at the front end portion of the front U-shaped roll ear body 3.8, and the front leaf spring rubber bush 3.6 is provided with a front spring for connecting to the longitudinal beam 1 of the vehicle body. Lug pin 3.5;

[0035] The rear ear includes a rear U-shaped ear body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com