A kind of preparation method of high molecular weight polylactic acid

A high-molecular-weight, polylactic acid technology, applied in the field of preparation of high-molecular-weight polylactic acid, can solve the problems of high preparation cost, difficult reaction, poor mechanical properties of polylactic acid, etc., and achieve the effects of improving mechanical properties and increasing molecular weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

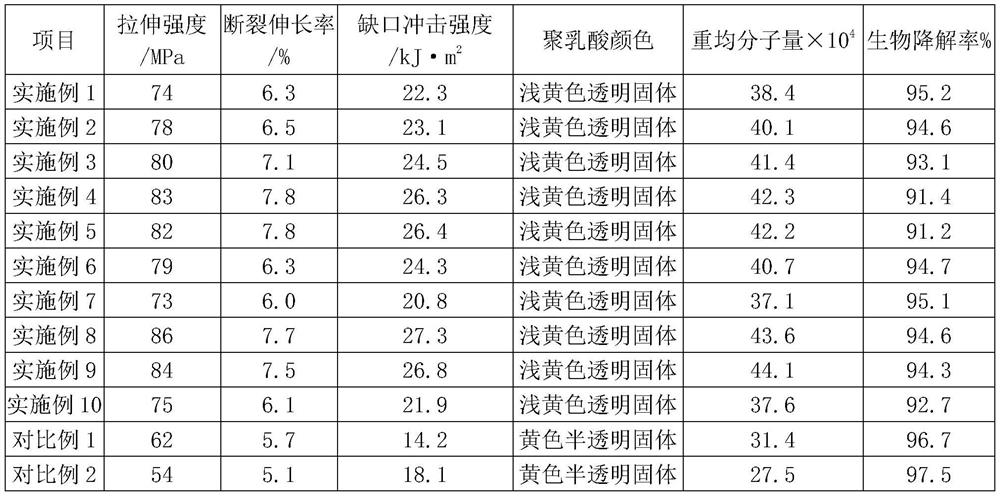

Examples

Embodiment 1

[0031] Prepolymerization: Raise the temperature in the reactor containing 100 parts of lactic acid and 5 parts of activated clay to 95°C, adjust the vacuum degree to 8KPa, dehydrate for 2 hours, and then raise it to 140°C, adjust the vacuum degree in the reactor to 7KPa, dehydration reaction 3h, the prepolymer was obtained.

[0032] Polymerization: Add 0.5 part of dibutyltin dichloride to the prepolymer obtained in the prepolymerization step, and stir and melt polymerize for 5 hours at a temperature of 150° C. and a vacuum of 5 KPa to obtain the first polymer.

[0033] The total amount of bisoxazoline chain extenders and polycarboxy compounds used in this example is 0.2% of the weight of lactic acid, and the weight ratio of bisoxazoline chain extenders and polycarboxy compounds is 5:1.

[0034] Chain extension: Add chain extender 2,2'-(1,3-phenylene)bisoxazoline to the first polymer obtained in the polymerization step, and stir the reaction at a temperature of 160°C and a vacu...

Embodiment 2

[0037] The rest is the same as in Example 1, except that the weight ratio of the chain extender 2,2'-(1,3-phenylene)bisoxazoline to the crosslinking agent citric acid is 10:1.

Embodiment 3

[0039] The rest is the same as in Example 1, except that the weight ratio of the chain extender 2,2'-(1,3-phenylene)bisoxazoline to the crosslinking agent citric acid is 15:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com