Full-automatic wall building process

A fully automatic, wall-building technology, which is applied in construction, building construction, and building material processing. It can solve the problems of labor-intensive workers, the stability of the lifting column's high center of gravity, and inability to move, so as to improve automation performance and improve Device stability, effect of improving mobile performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

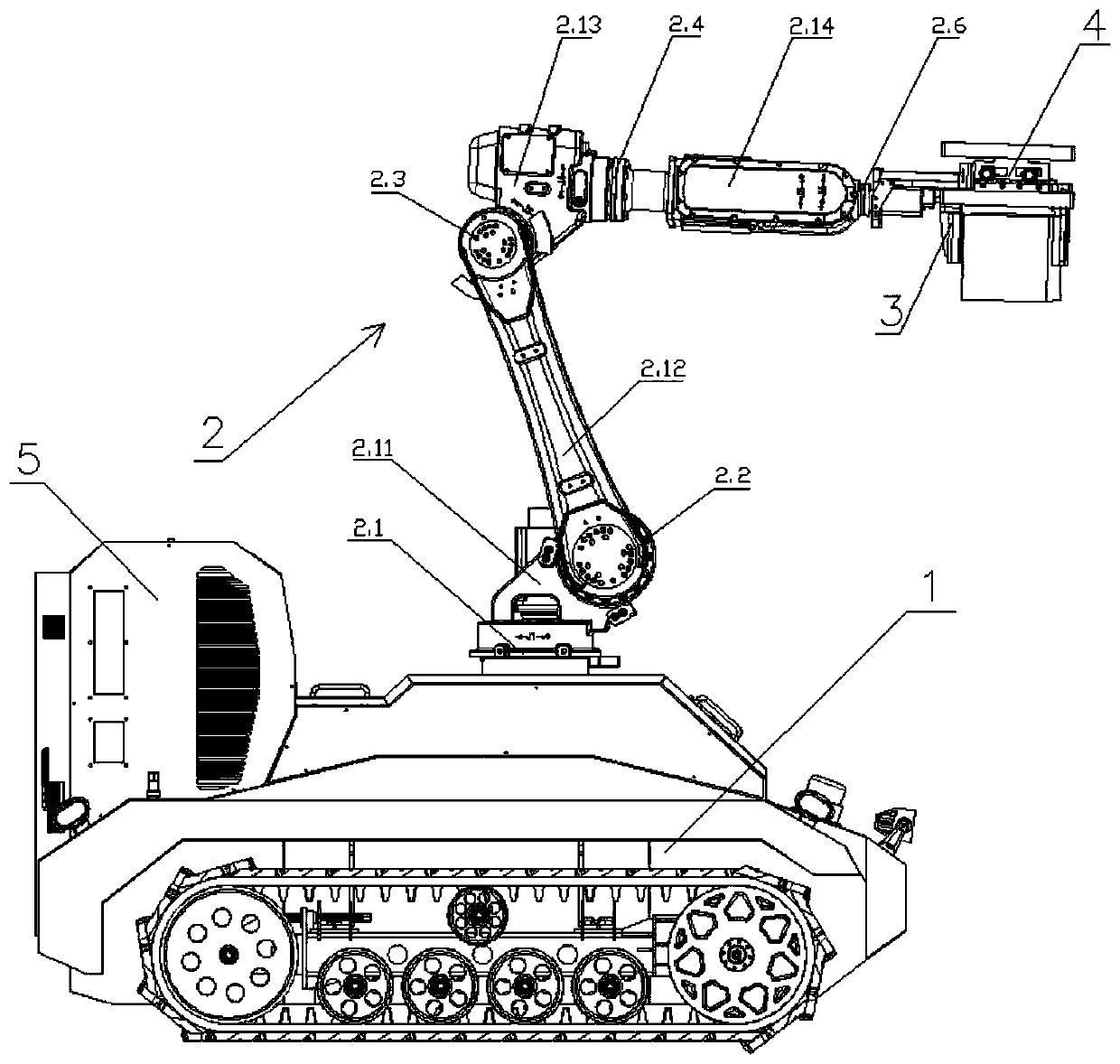

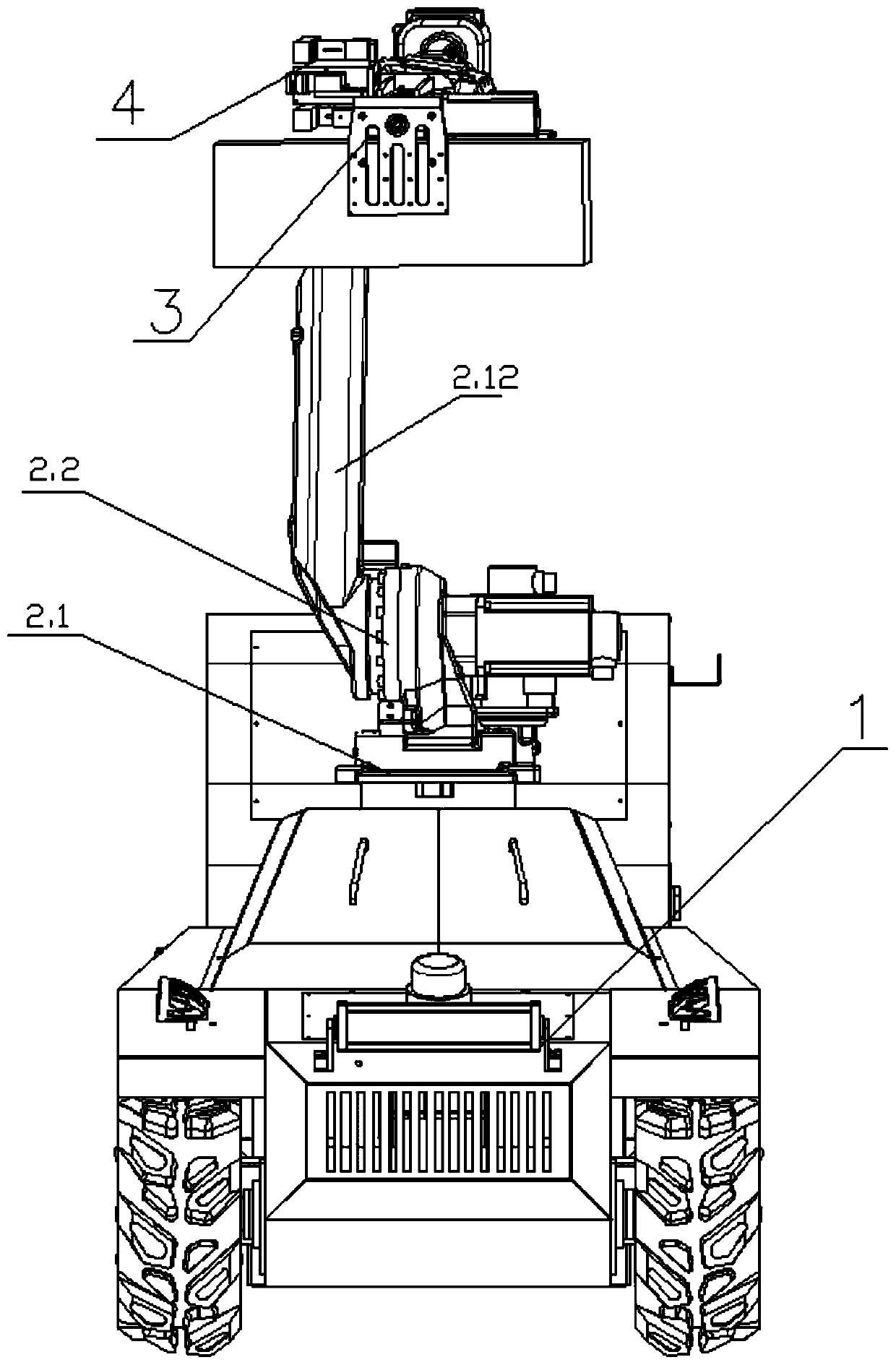

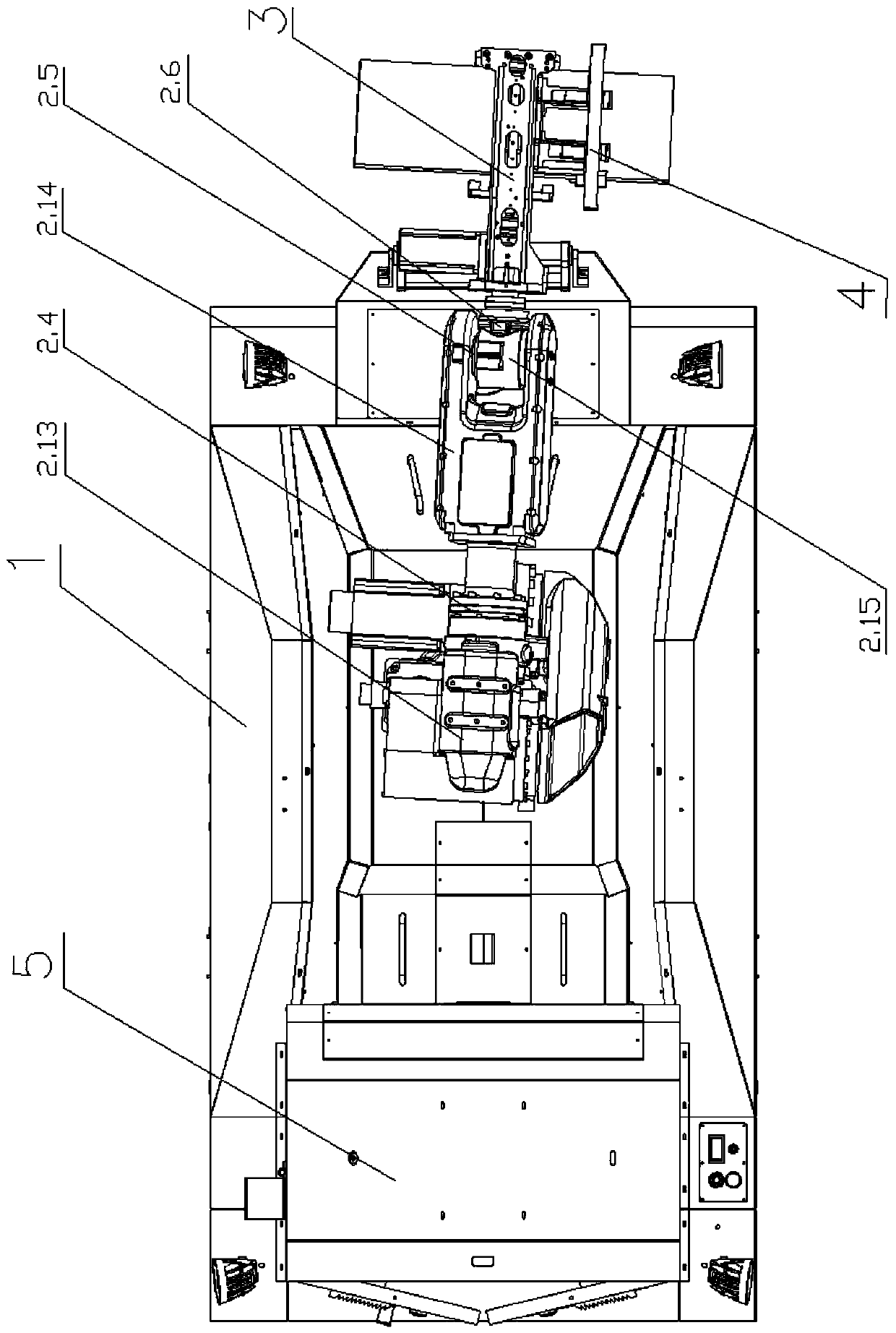

[0039] see Figure 1-10 , a kind of fully automatic wall-building process that the present invention relates to, described process step is:

[0040] Step 1. The wall-laying robot is in place: the wall-laying robot with a crawler-type walking mechanism enters the construction site and travels to the construction position;

[0041] Step 2, block placement: at least two pallets loaded with blocks are transported to the construction site;

[0042] Step 3, clamping: the multi-axis mechanical arm of the wall-laying robot drives the clamping mechanism to move to the pallet to clamp the block;

[0043] Step 4, Putting the mortar in place: the clamping mechanism moves to the bottom of the mortar head under the drive of the multi-axis mechanical arm;

[0044] Step 5, plastering 1: In the process of plastering the mortar on the surface of the block by the mortar plastering head, the clamping mechanism holding the block is driven by the multi-axis mechanical arm to perform a translation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com