Method for testing absorption energy of ore by using drop hammer impact

A drop hammer impact and energy absorption technology, which is applied to measuring devices, instruments, scientific instruments, etc., can solve problems such as inflexible operation, unsatisfactory ore crushing effect, and small energy range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is described in detail below in conjunction with embodiment and accompanying drawing.

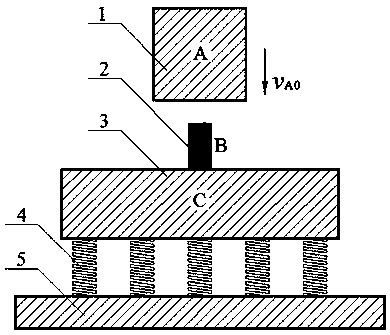

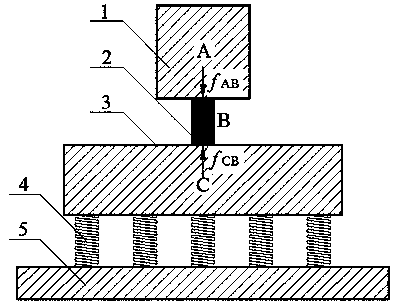

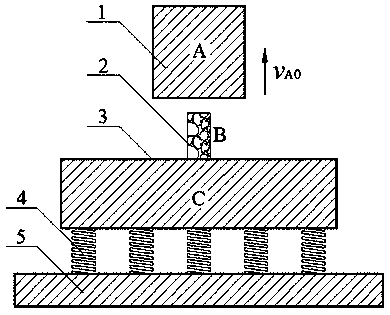

[0027] see Figure 1 to Figure 3 , a method of testing the energy absorbed by ore using a drop hammer impact, which is carried out as follows:

[0028] Establish a physical model of the ore impacted by the drop hammer 1. The physical model is composed of the drop hammer 1, the specimen 2, the base 3, the spring 4 and the base 5, and the spring 4 is installed between the base 3 and the base 5; 1 is in free fall, the gravitational potential energy of drop hammer 1 is converted into kinetic energy, and the kinetic energy at the moment of contact between drop hammer 1 and specimen 2 is used as impact energy, as shown in formula (1); part of the impact energy is used in specimen 2 during the impact process Part of the broken energy is transformed into the kinetic energy of the downward movement of the base 3, and the remaining energy is the kinetic energy of the reb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com