Remote-control automatic high-voltage test system

A high-voltage testing and automatic technology, which is applied in the direction of automatic testing system, electronic circuit testing, testing dielectric strength, etc., can solve the problems of increasing the risk of high-voltage debugging of errors, low degree of automation, and difficulty in all updates, etc., to achieve fast and accurate The effect of completing the test, reducing the probability of errors, and eliminating errors in settings and judgments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

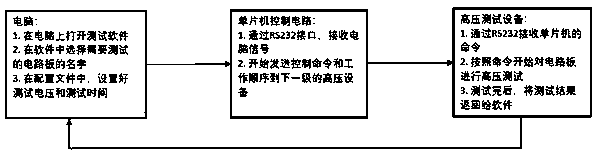

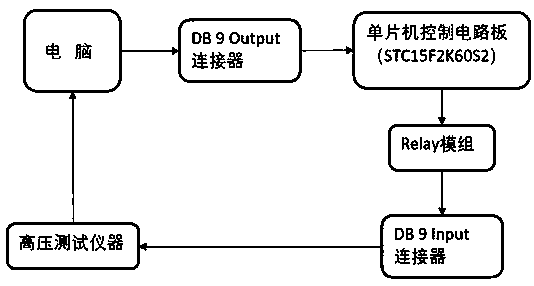

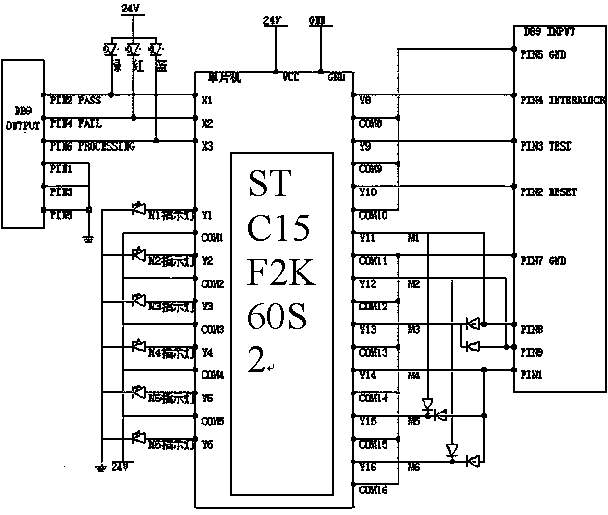

[0028] A remote automatic high-voltage testing system, including a computer and a high-voltage testing instrument, characterized in that the computer forms a control channel with a single-chip controller through an output signal connector, and the output port of the single-chip controller is connected to a relay module. The relay module forms a control channel with the high-voltage testing instrument through an input signal connector.

[0029] The model of the single-chip controller is STC15F2K60S2.

[0030] The high voltage testing instrument is HT8500 AC and DC withstand voltage / insulation resistance tester.

[0031] See attached figure 2 , 3 , the single-chip microcomputer control circuit controls the relay to work according to the requirements of the soft armor, and then controls the voltage output and test time of the high-voltage equipment through the RS232 serial port.

[0032] The software sends instructions to control the relay to work, and after a delay of 300 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com