Multifunctional industrial robot intelligent manufacturing system and manufacturing method

An industrial robot and intelligent manufacturing technology, applied in the field of manufacturing systems, can solve problems such as affecting the quality of laser coding, rising temperature, and increasing manufacturing costs, so as to improve the quality of coding and marking, avoid inconsistencies in progress, and save working space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

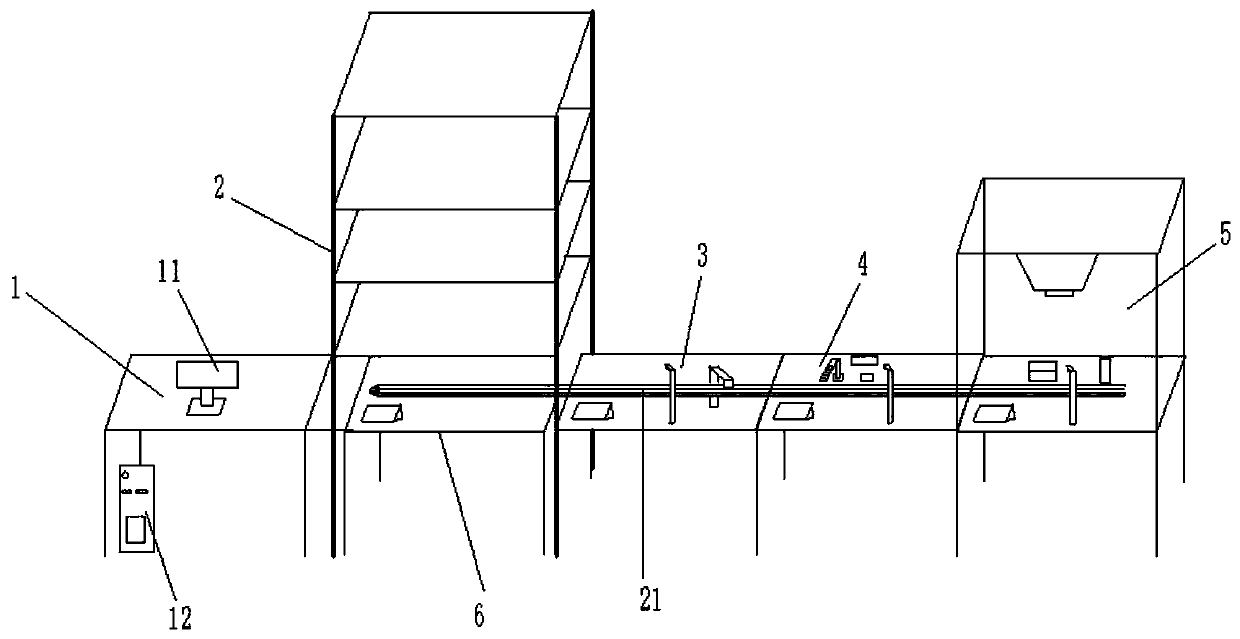

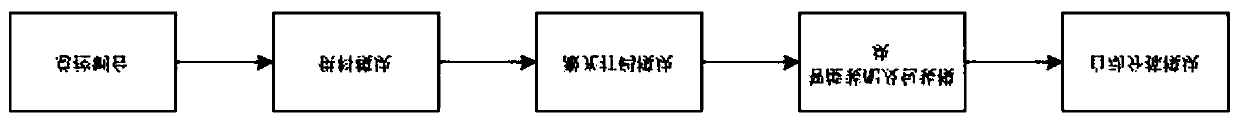

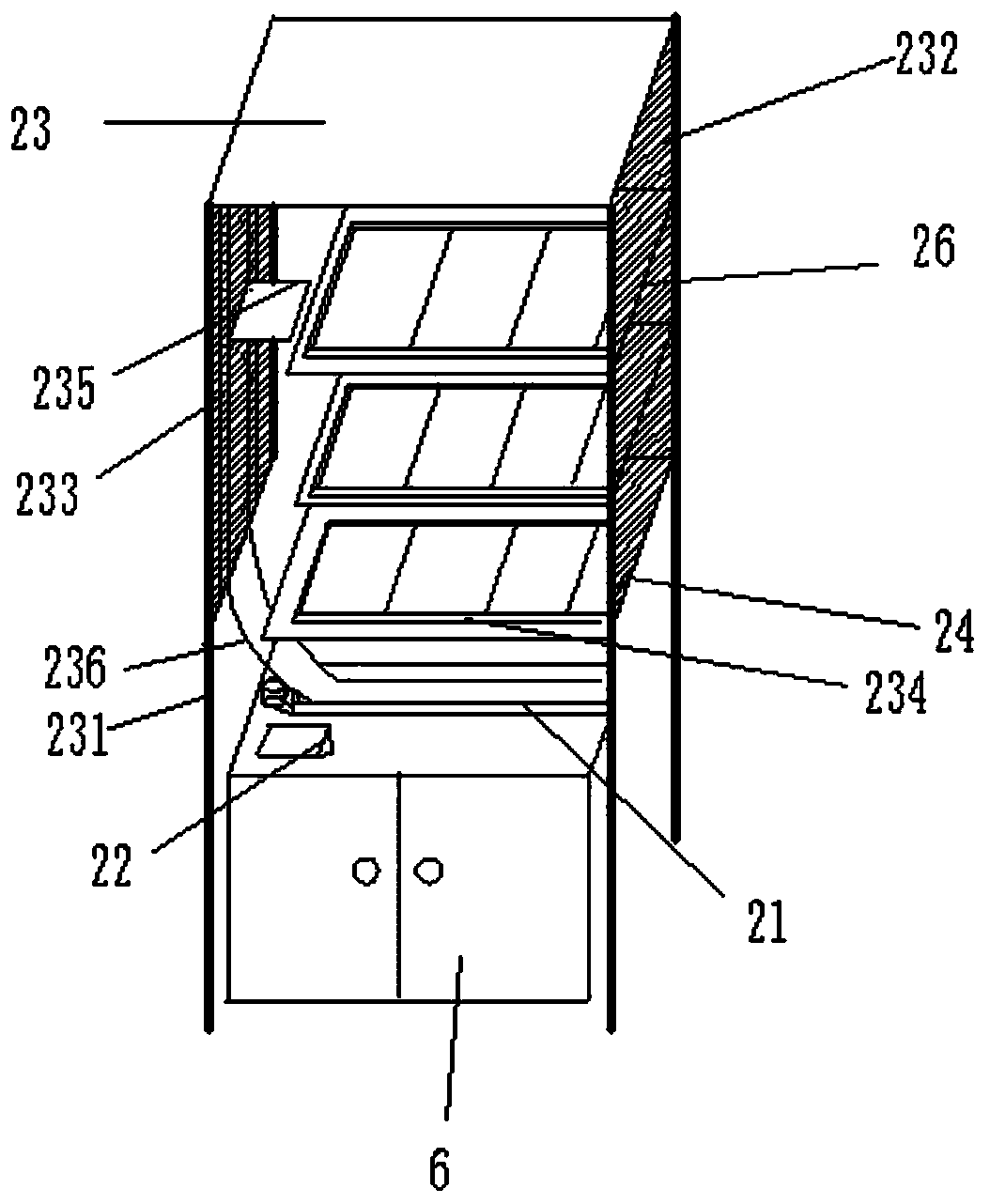

[0074] Embodiment: refer to attached Figure 1-4 , Figure 5a , Figure 5b , Figure 6-17 As shown, the present invention uses the U disk as the carrier to realize the assembly and manufacturing process, and the materials are respectively a tray, a U disk and a packing box, wherein the U disk is divided into a lower shell, a chip, an upper shell, and a cap, and the packing box is divided into an upper cover and a lower cover , U disk is purchased as a standard part, which can be divided into lower shell, chip, upper shell and cap.

[0075] The main technical parameters of the manufacturing system: (1) Input power: three-phase five-wire AC380V ± 10% 50Hz. (2) Machine power: <5kVA. (3) Dimensions: no more than 6000mm×1200mm×2000mm. (4) Air source pressure: 0.5Mpa. (5) Working environment: temperature -5℃~+40℃; humidity 85% (25℃); altitude <4000m.

[0076] A multifunctional industrial robot intelligent manufacturing system and manufacturing method, a multifunctional indust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com