Hydrogen peroxide atomization sterilizing device and method

A sterilizing device and hydrogen peroxide technology, applied in the field of bottle blowing, can solve the problems of low sterilizing efficiency, increased injection volume, increased sterilizing time and sterilizing cost, and achieve the effects of low sterilizing cost, short sterilizing time and high sterilizing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

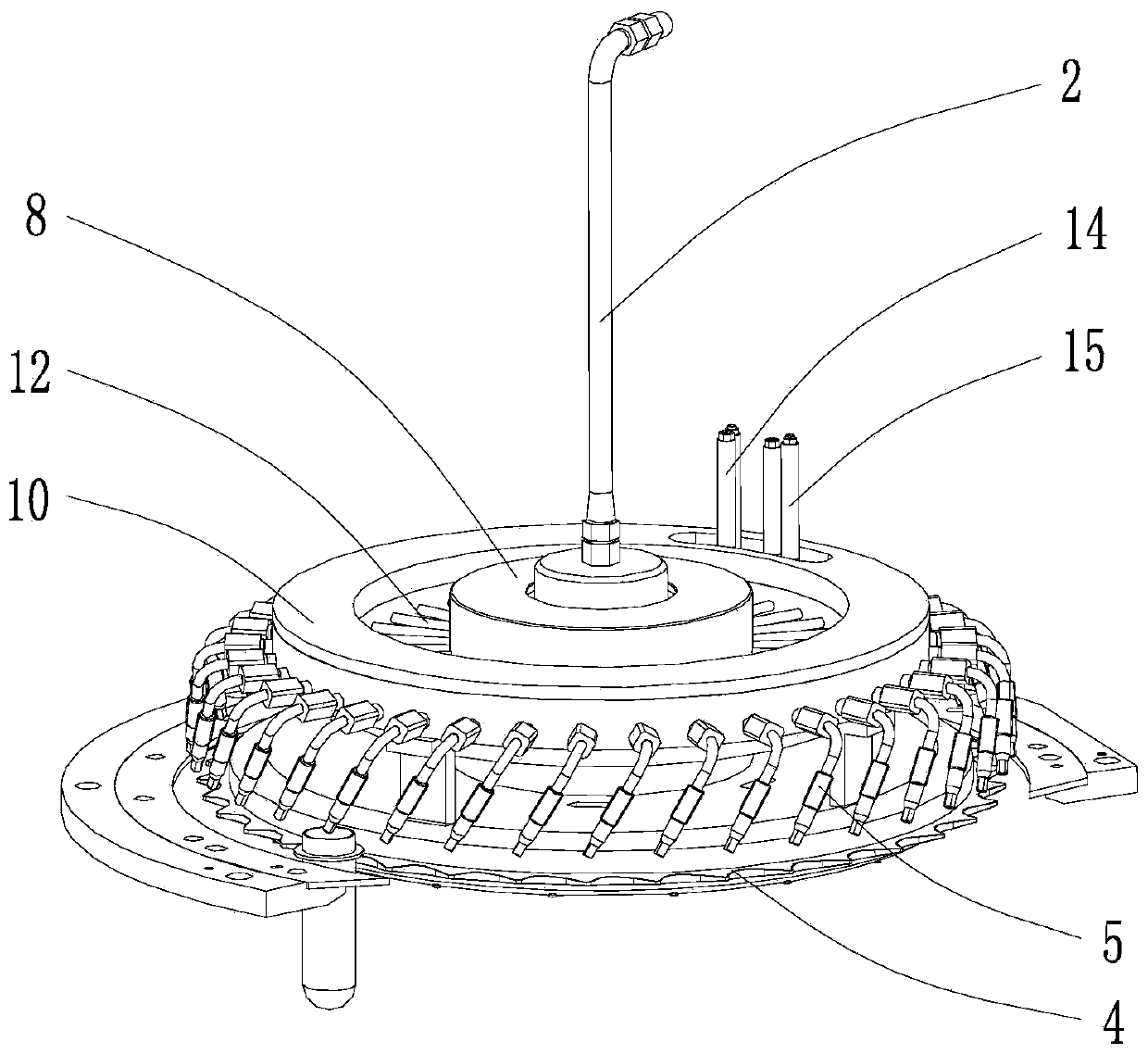

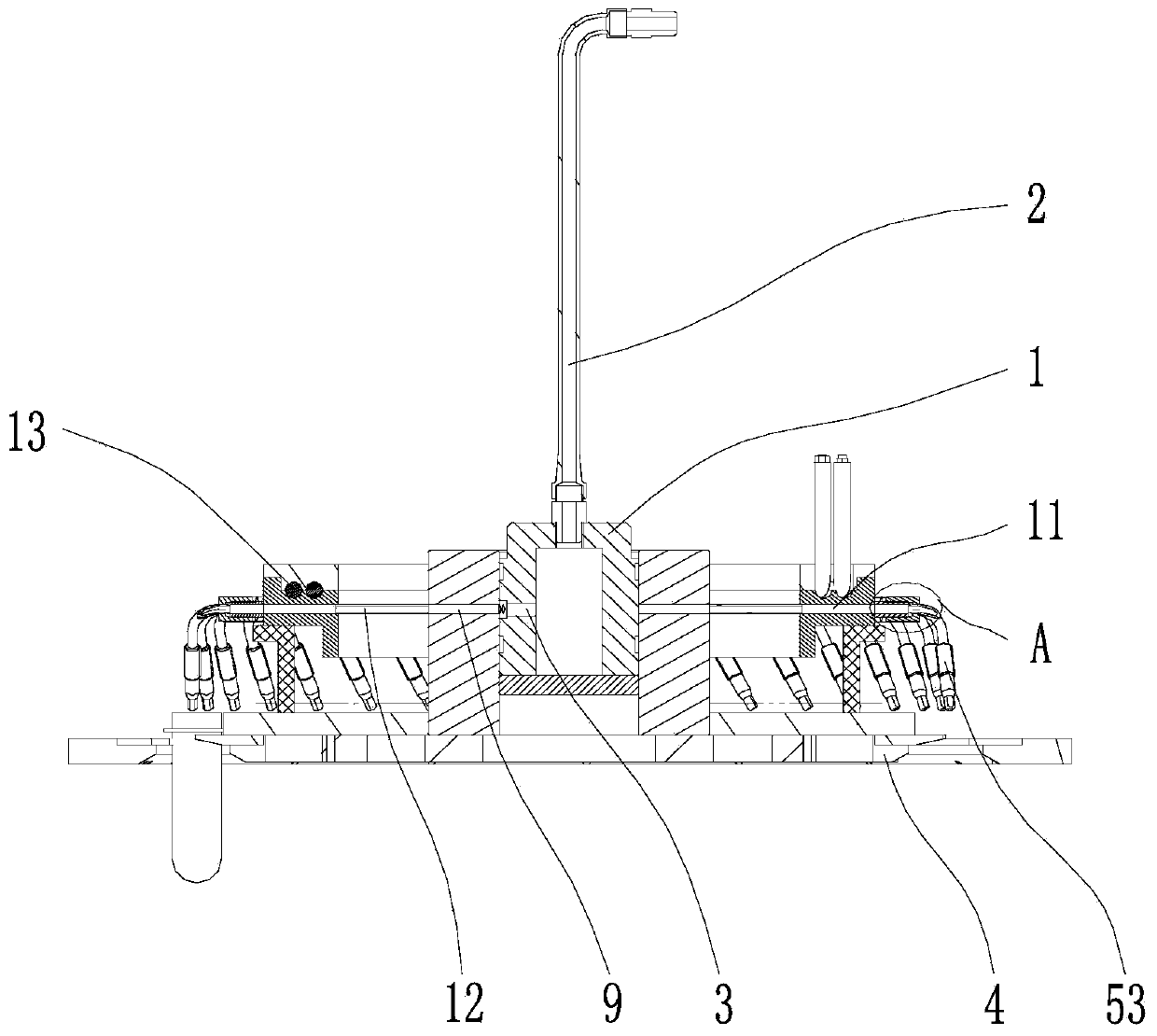

[0025] see Figure 1-4 As shown, the above-mentioned hydrogen peroxide atomization sterilization device includes a distributor 1 fixed on the frame, an air inlet pipeline 2 communicated with the distributor 1, an air outlet pipeline 3 opened in the distributor 1, and a On the disk 4 and extending coaxially, there is an annular receiver set on the outside of the distributor 1, and a plurality of injection nozzles 5 arranged on the annular receiver evenly spaced along the circumferential direction; the dial 4 can rotate around its own axis The one rotating in the line direction is arranged on the frame, and the dial 4 extends coaxially with the ring receiver. The air intake pipeline 2 is communicated above the distributor 1 , and the air outlet pipeline 3 is opened on the side of the distributor 1 .

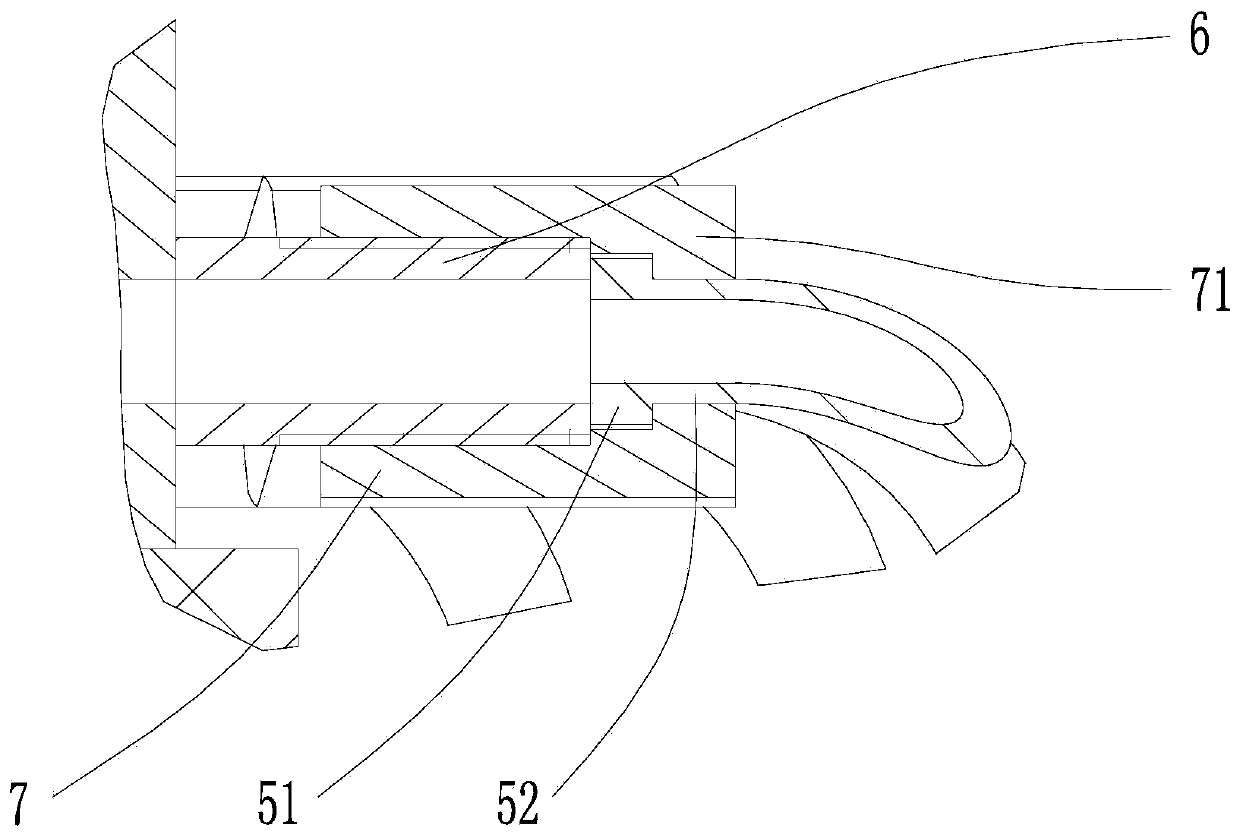

[0026] The injection nozzle 5 is used to c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com