Automatic adjustment detection system

An automatic adjustment and detection system technology, applied to sports accessories, horizontal bars, gymnastic equipment, etc., can solve the problems of large influence, inaccurate training and assessment of horizontal bars, lack of basis for training and assessment results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

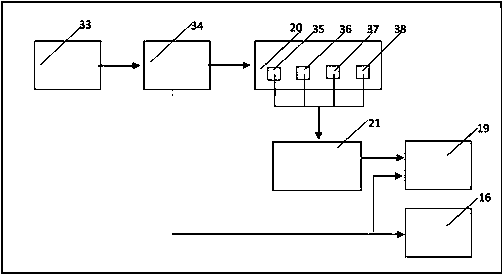

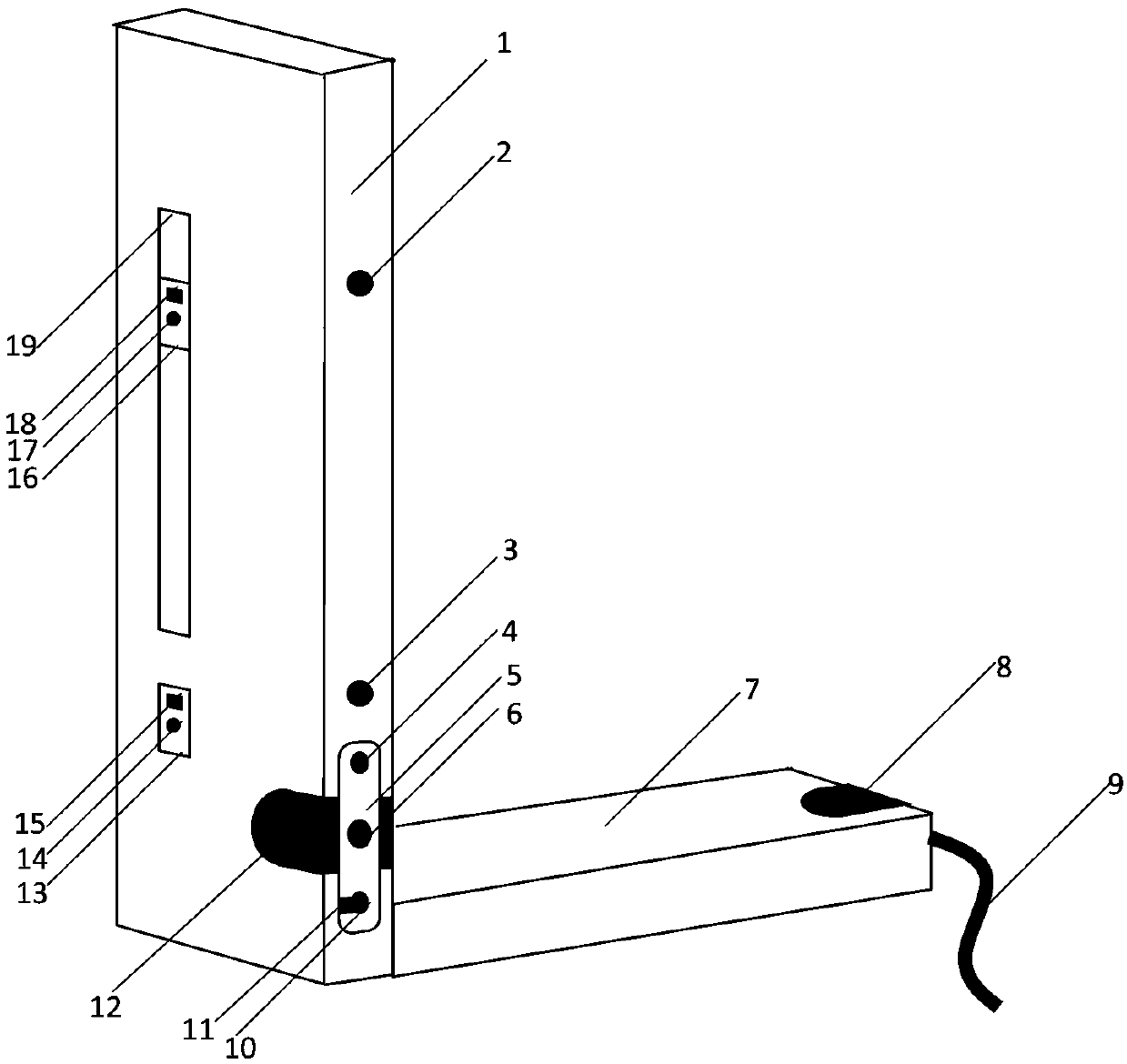

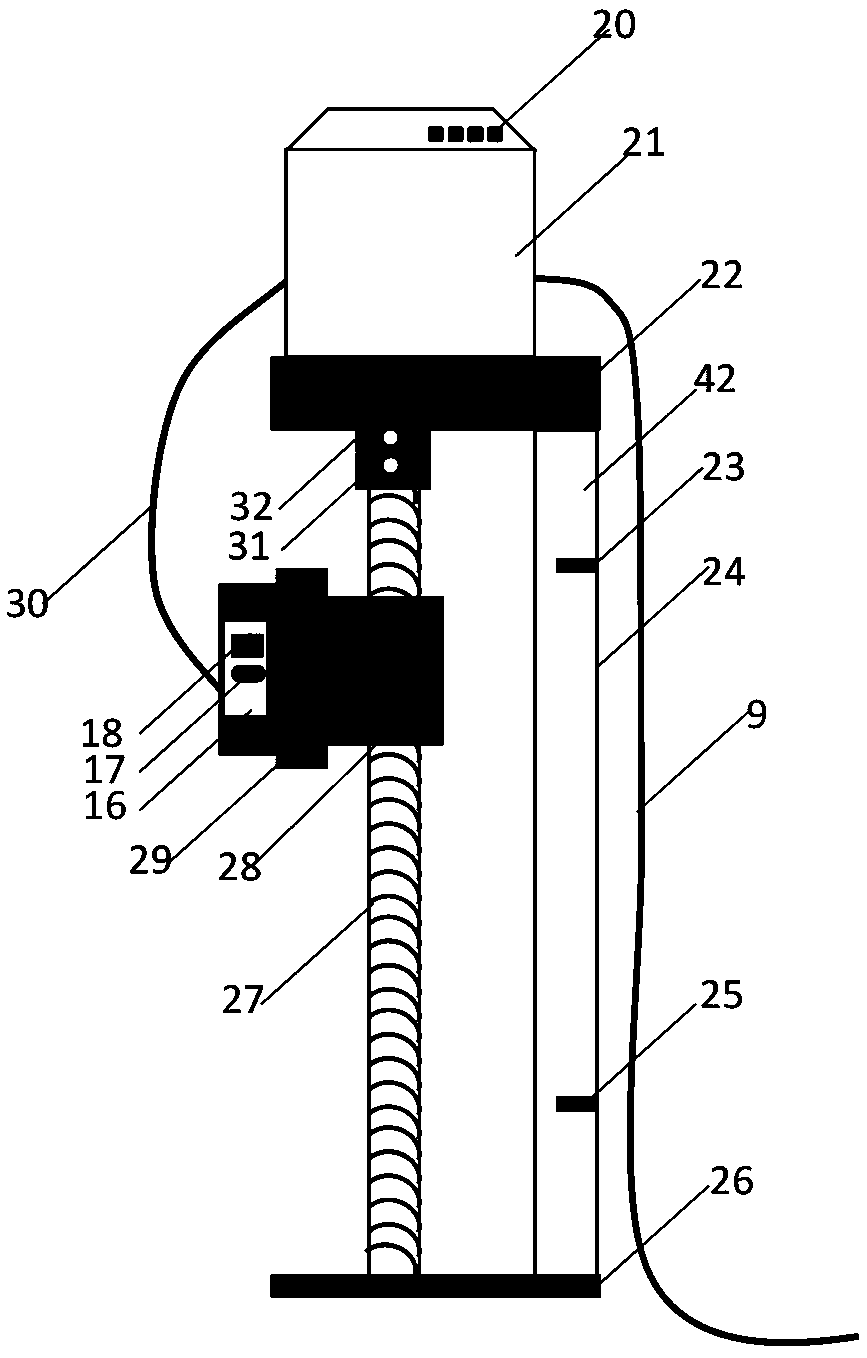

[0048] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, when applied to the examination of sports horizontal bar items, the stepper motor control module (20) and the photodetector A (13), the photodetector A (13), and the Sensitive detector B (16); Described upper computer module (33), through control line stepping motor (21) left turn control (35), right turn control (36), acceleration (37), deceleration (38), Connect the signal collected by photodetector A (13) and photodetector B (18) through data interface (34), judge the standard and quantity by host computer module (33), and measure the assessment time; the stepper motor control The module (20) accepts the control signal of the host computer, calculates the face height data according to the height ratio of the examiner, automatically adjusts the position of the high-level light-sensing detector, and remembers the position of the adjustment slide (22).

Embodiment 3

[0050] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, it is applied to the sports horizontal bar pull-up project assessment. The automatic adjustment detector (1) is installed on the horizontal bar, and a communication connection is established with the upper computer module (33). 33) Fingerprint collection and verification of identity information and height information, the host computer calculates the head information of the reference person through the height information, and automatically adjusts the exact position of the light-sensitive detector B (16) on the detector (1); when the training assessment starts When the reference person reaches the high position from the low position, count one. When the high position is not reached, it is regarded as not up to the standard and no counting is performed. When the first high position is detected, the timing starts, and the time is automatically counted according to the set time. After that, the assessment is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com