Wire drawing equipment for cable production

A wire drawing and cable technology, which is applied in the field of cable processing and production, can solve the problems that affect the normal wire drawing accuracy of wire drawing, poor design of guide rollers or guide devices, low wire drawing tension maintenance effect, etc., and achieve good wire tension maintenance effect. Improve wire drawing efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

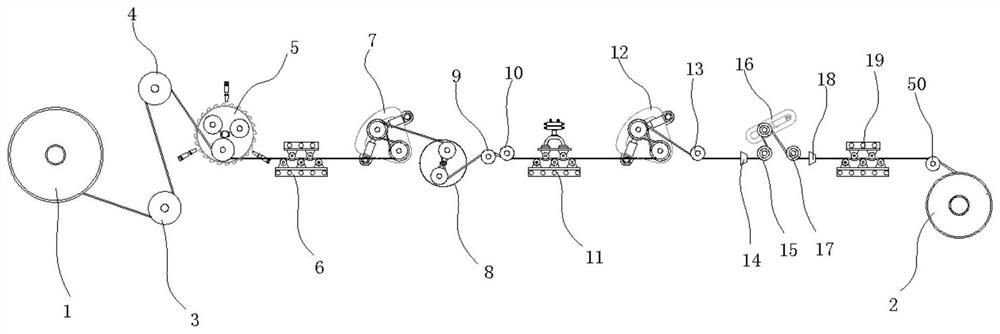

[0036] A wire drawing equipment for cable production, comprising a pay-off roller 1 and a take-up roller 2, characterized in that a first guide roller 3 and a second guide roller 4 are sequentially arranged between the pay-off roller 1 and the take-up roller 2 , the first wire drawing mechanism 5, the first guide assembly 6, the second wire drawing mechanism 7, the third wire drawing mechanism 8, the third guide roller 9, the fourth guide roller 10, the movable guide assembly 11, the fourth wire drawing mechanism 12. The fifth guide roller 13 , the first wire drawing die 14 , the sixth guide roller 15 , the movable guide roller assembly 16 , the seventh guide roller 17 , the second wire drawing die 18 , the second guide assembly 19 and the eighth guide roller 50 .

[0037] In this embodiment, the wire is drawn through a multi-stage guiding and drawing mechanism.

Embodiment 2

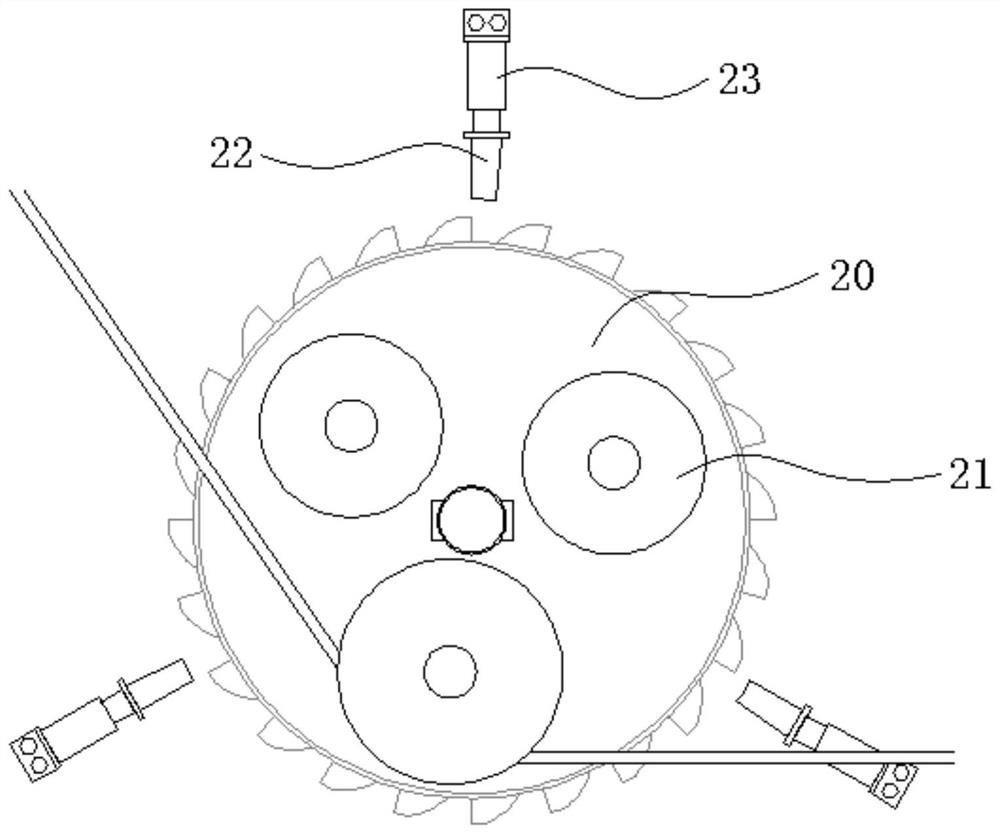

[0039] A wire drawing equipment for cable production in this embodiment, wherein the first guide roller 3 and the second guide roller 4 are distributed up and down, and the first wire drawing mechanism 5 includes a first rotating panel 20 and a first wire drawing roller 21 and ratchet 22, the first rotating panel 20 is circular, the middle of which is connected to a motor, and the rotation is controlled by the motor. A circle of ratchets is provided around the circle of the first rotating panel 20. The claws 22 are correspondingly matched, and the number of the ratchets 22 is multiple, evenly distributed on the periphery of the first rotating panel 20, and its rear end is connected with the first cylinder 23, and stretches and shrinks through the first cylinder 23, and the first rotation 20 locking panels;

[0040]Wherein, the number of the primary drawing rollers 21 is multiple, and the plurality of primary drawing rollers 21 are rotatably arranged on the first rotating panel...

Embodiment 3

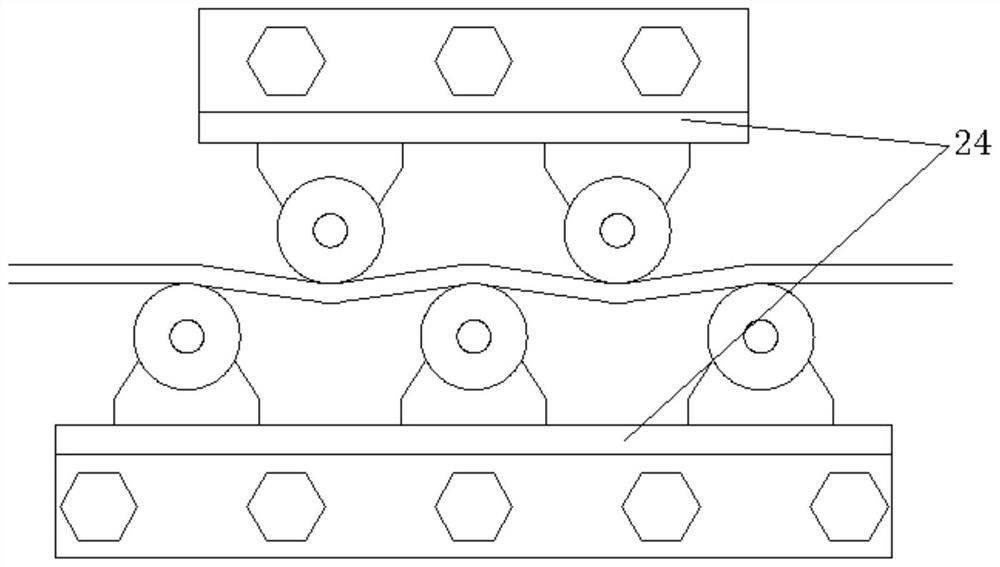

[0043] A wire drawing device for cable production in this embodiment, wherein the first guide assembly 6 and the second guide assembly 19 have the same structure, and both are composed of roller seats 24 arranged up and down oppositely, and the roller seats 24 are fixedly arranged, A plurality of freely rotating shaft rollers are uniformly arranged on it.

[0044] In this embodiment, the guide assembly is used to guide the drawing direction of the wire, and has a certain function of maintaining the tension of the wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com