Steel bar net cage net combining method

A steel mesh and networking technology, applied to the online network, other household appliances, household appliances, etc., can solve the problems of labor-intensive, not well adapted to the production of autoclaved aerated concrete, and low networking efficiency, so as to improve efficiency , to ensure accuracy, and to speed up the effect of networking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

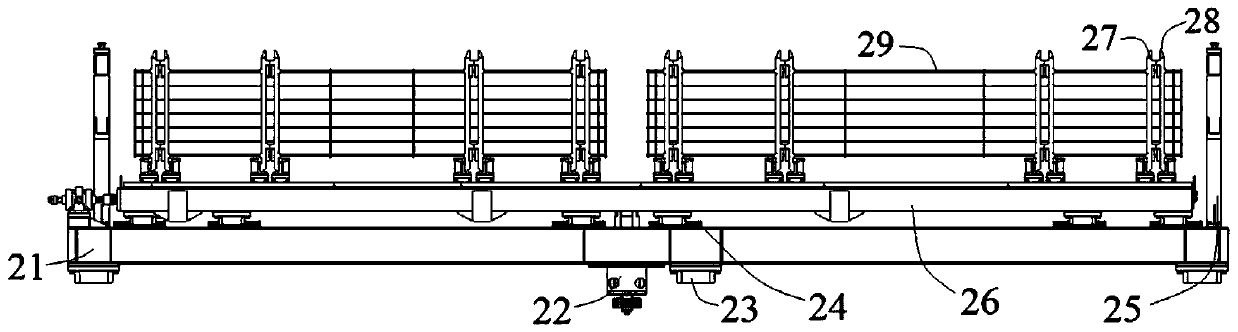

[0049] combine image 3 , a reinforced mesh cage networking trolley in this embodiment includes a first trolley frame 21 , a first moving frame 26 , a first moving assembly 27 , a second moving assembly 28 and a second moving frame 210 . The first moving assembly 27 can be provided with different numbers along the length direction of the first moving frame 26 according to the steel mesh cage 29 of different specifications. Specifically, in this embodiment, 8 first moving assemblies are arranged along the length direction of the first moving frame 26 27. The second moving assembly 28 can be provided with different numbers along the length direction of the second moving frame 210 according to the reinforced mesh cage 29 of different specifications. Components 28, the first moving component 27 and the second moving component 28 are arranged in pairs, and cooperate with each other to position and fix the steel mesh cage 29.

[0050] combine Figure 8 , the second moving frame 2...

Embodiment 2

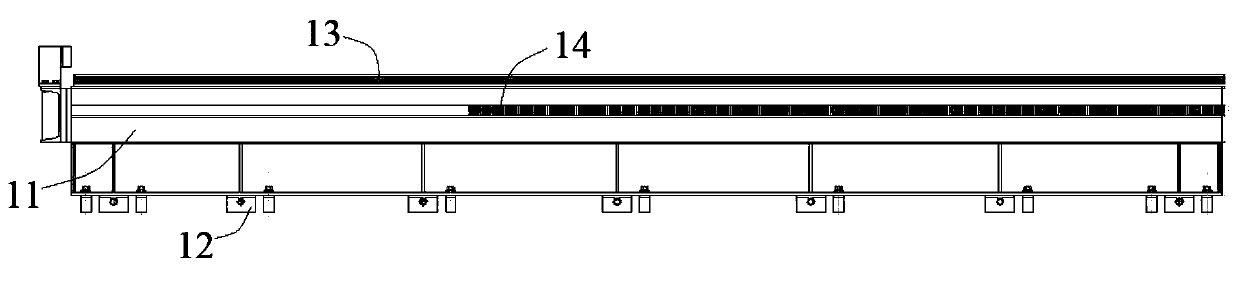

[0054] combine figure 2 , this embodiment relates to a kind of network equipment using a network trolley for reinforced mesh cage networking, including a base 1 and a networking trolley as described in Embodiment 1, the base 1 includes a base frame 11, a shim 12, a base guide rail 13 and Transmission rack 14. The base guide rail 13 and the transmission rack 14 are arranged on the base frame 11 along the length direction, and the shims 12 are arranged at intervals along the length direction of the base frame 11 for adjusting the height of the base frame 11 . The lower end of the networking trolley is provided with a transmission assembly 22 and a first slider 23, the transmission assembly 22 includes a gear 221 and a transmission base 222, the bottom of the networking trolley is provided with a transmission base 222, and the transmission base 222 is connected to the gear 221, and the gear 221 is connected to the base 1 gear rack 14 engagement. The gear 221 of the transmissio...

Embodiment 3

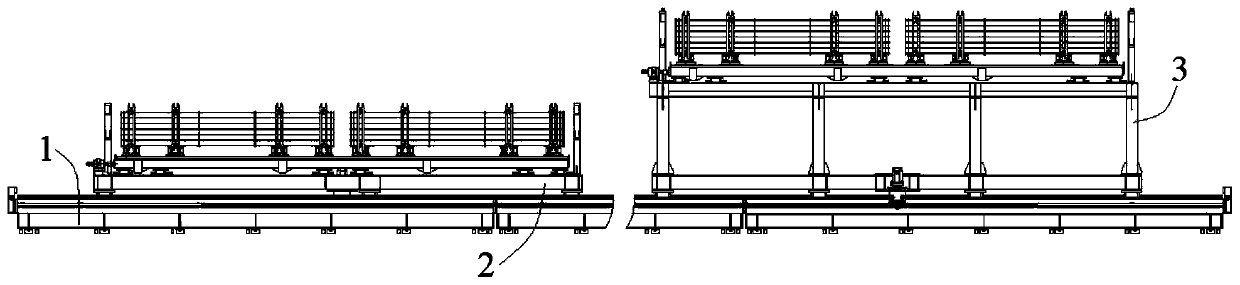

[0056] combine figure 1 and Figure 5 , a reinforced mesh cage networking equipment in this embodiment is basically the same as in Embodiment 2, except that the networking equipment includes two networking trolleys, that is, the first trolley 2 and the second trolley 3, wherein the first trolley The second trolley frame 31 of the second trolley 3 is higher than the first trolley frame 21 of the first trolley 2, the two trolleys are arranged in layers, and the base 1 is respectively provided with a base for the first trolley 2 and the second trolley 3 The guide rail 13 and the transmission rack 14 enable the two trolleys to move back and forth on the base 1 at the same time, and form a network separately without interfering with each other, thereby improving the efficiency of the network.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com