Method for customizing inner right-angle arc chamfer sawing of furniture plate

A technology of circular-arc chamfering and right-angle, which is applied in the field of right-angle circular-arc chamfering and sawing in custom-made furniture panels. It can solve problems such as incomplete chamfering, damaged board skin, and inability to fit perfectly, so as to improve processing efficiency and processing accuracy. , maintain synchronization and coherence, and avoid the effect of sheet skin damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

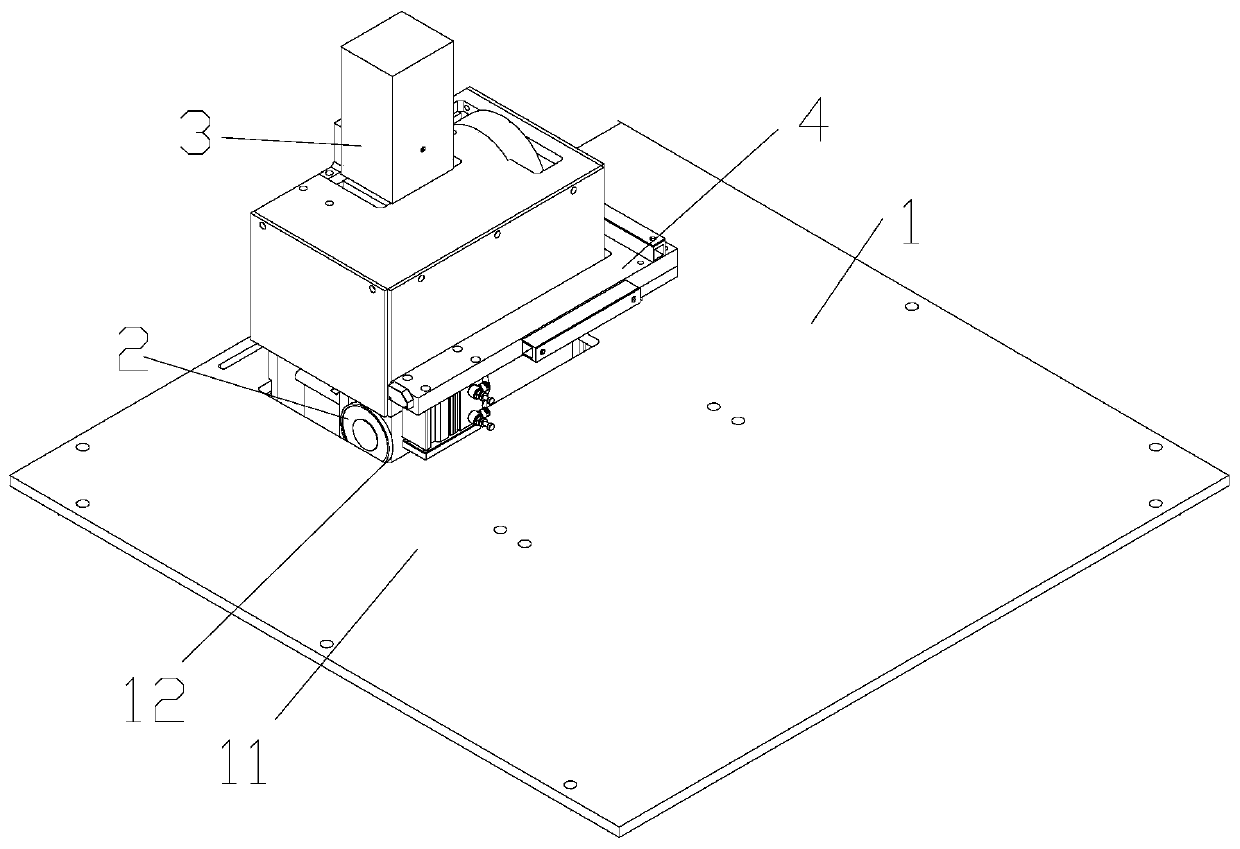

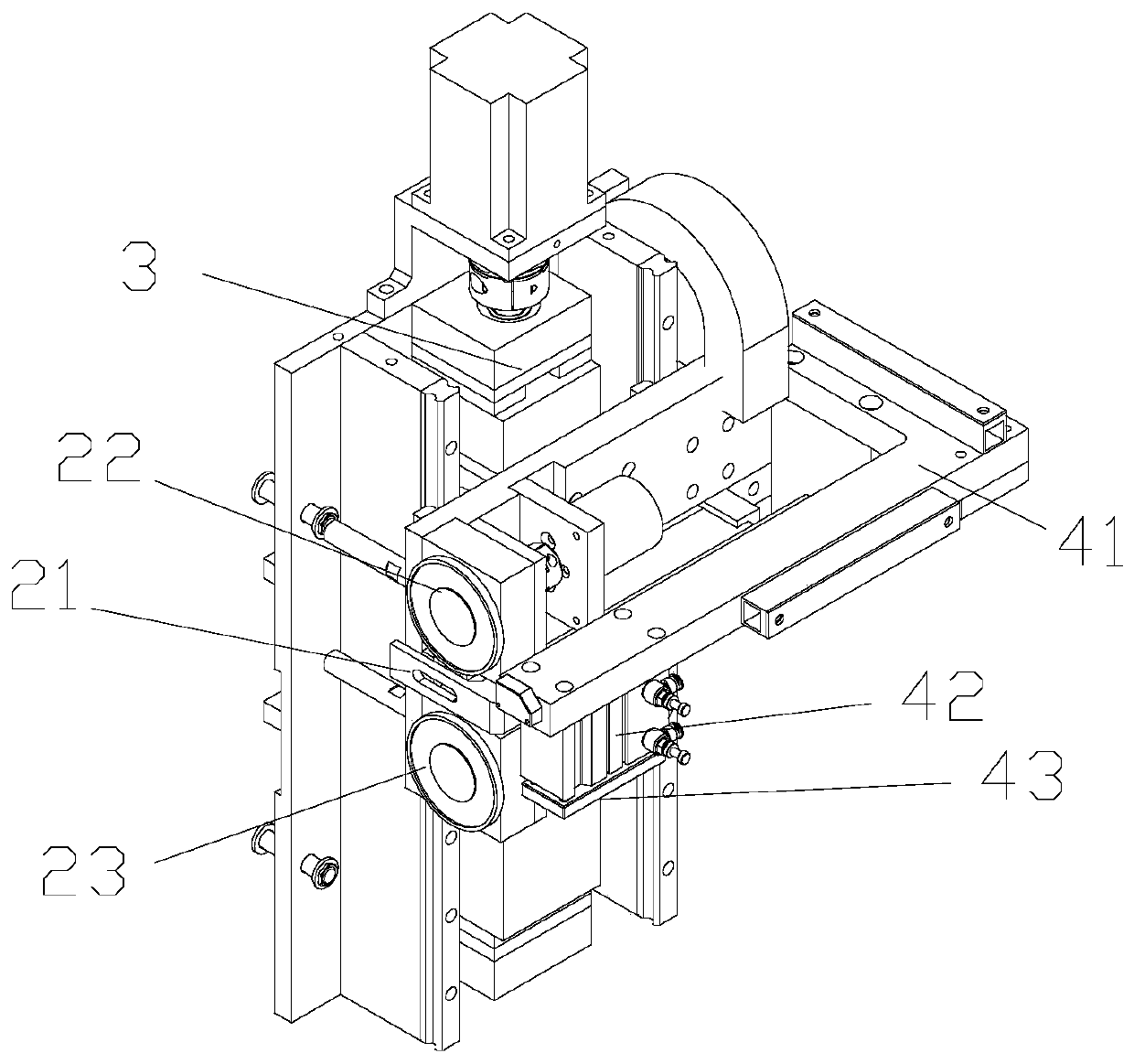

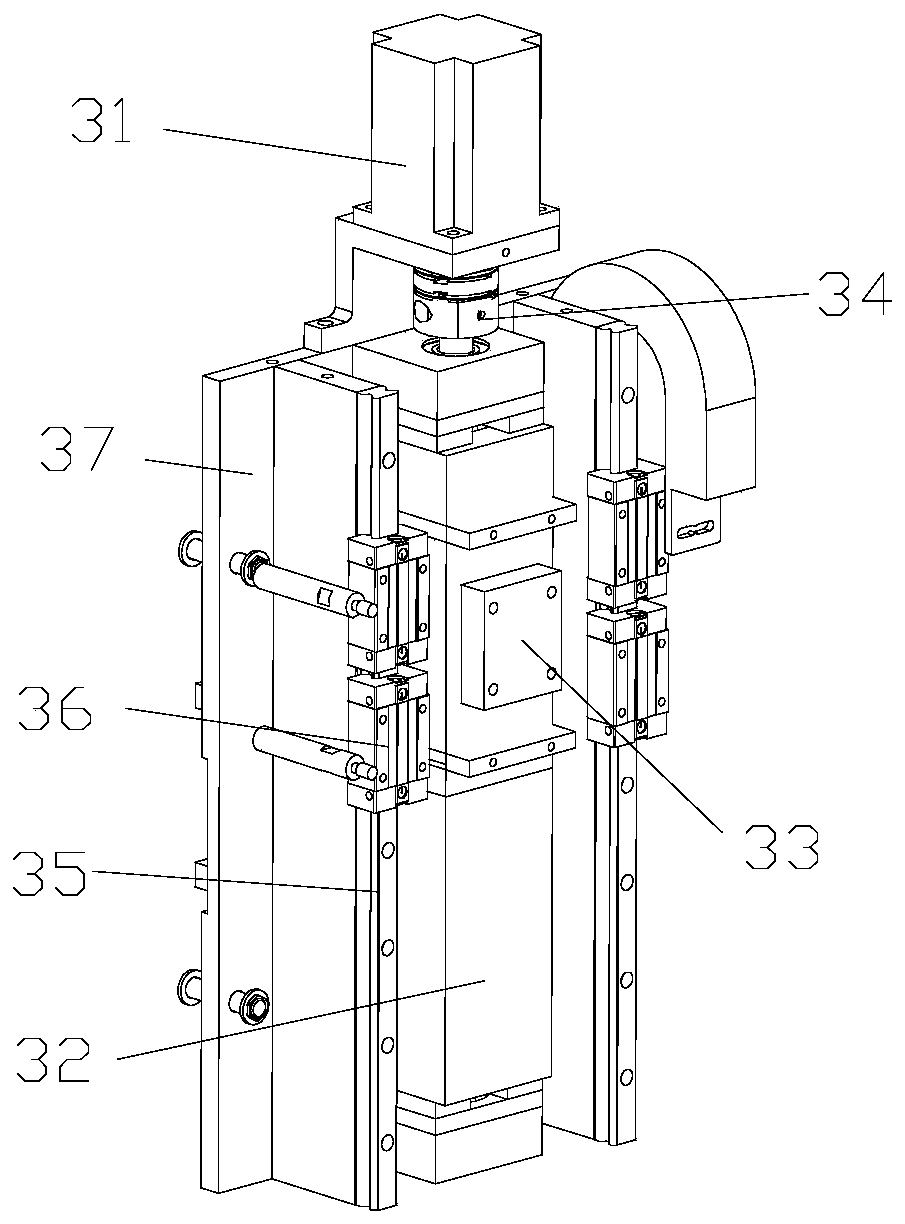

[0032] This embodiment is a method for customizing the right angle circular arc chamfering and sawing of the inside of the furniture board, loading, positioning and fixing the board to be processed; using the combined sawing method of the upper cutting saw assembly and the lower cutting saw assembly to cut the inside of the board to be processed Right-angle arc chamfering and sawing: first cut saw the inner right-angle arc chamfer of the plate to be processed from top to bottom or from bottom to top along the thickness direction of the plate. Right-angled arc chamfering, and then cut and saw the inner right-angled arc chamfering of the plate to be processed along the thickness direction of the plate, so that all the inner right-angled arc chamfering can be sawed.

[0033] The method of the present invention can realize the automatic cutting and sawing processing of right-angled arc chamfering inside the board, can save labor costs, improve the processing efficiency and processi...

Embodiment 2

[0062] This embodiment is a method for customizing the inner right-angled arc chamfering of the furniture plate. First, the inner right-angled arc chamfering of the plate to be processed is sawed from top to bottom or from bottom to top along the thickness direction of the plate. The sawing stroke is less than the thickness of the plate to incompletely cut the inner right angle circular arc chamfering, and the sawing stroke is preferably 50% to 90% of the thickness of the plate. The rest of the method in this embodiment is the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com