Sponge crushing treatment device for waste recovery

A treatment device and waste technology, applied in the direction of grain treatment, plastic recycling, recycling technology, etc., can solve the problems of increased loss, feed or discharge blockage, waste of resources, etc., to improve crushing efficiency, avoid blockage, reduce waste, etc. The effect of small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

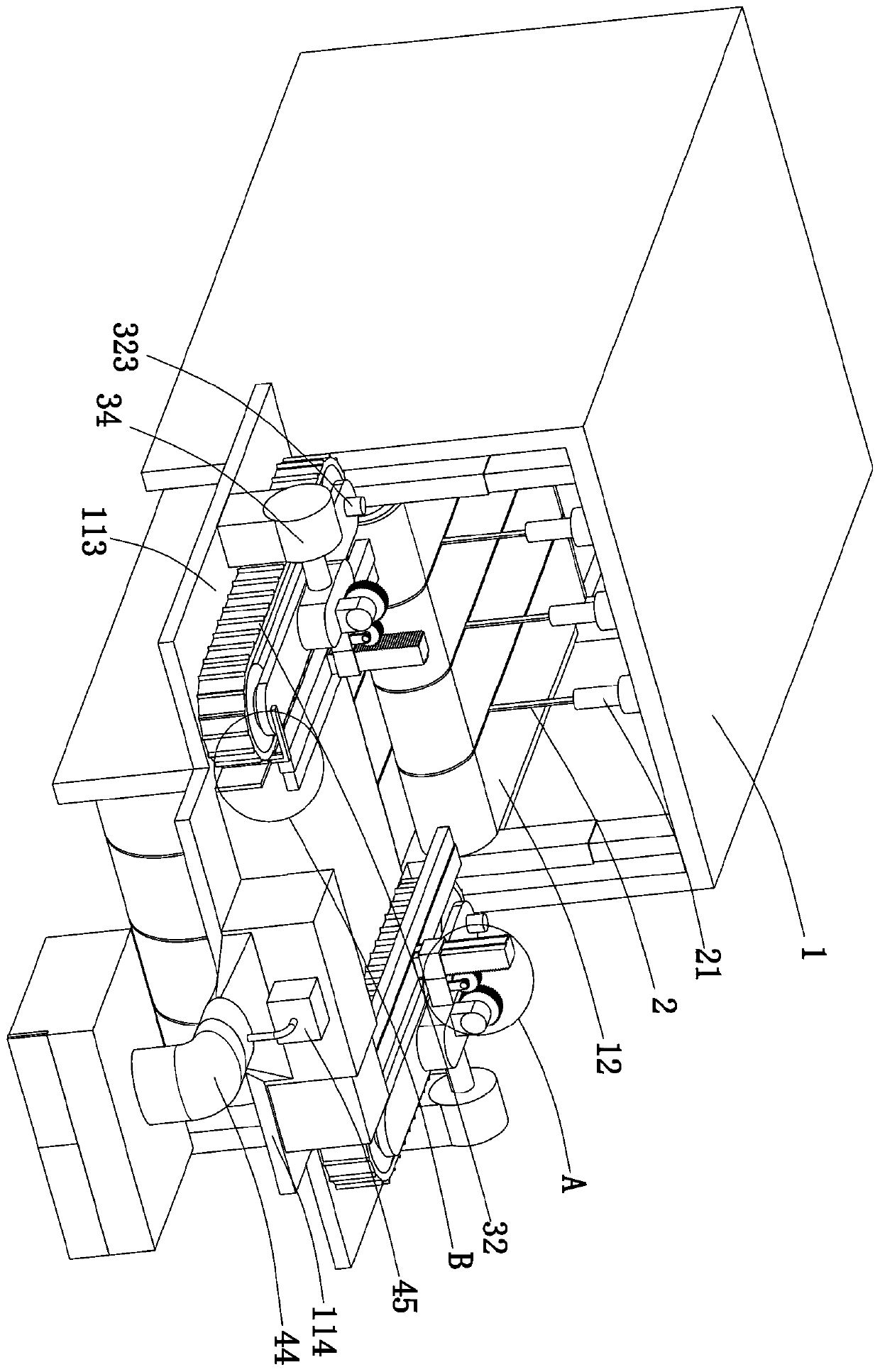

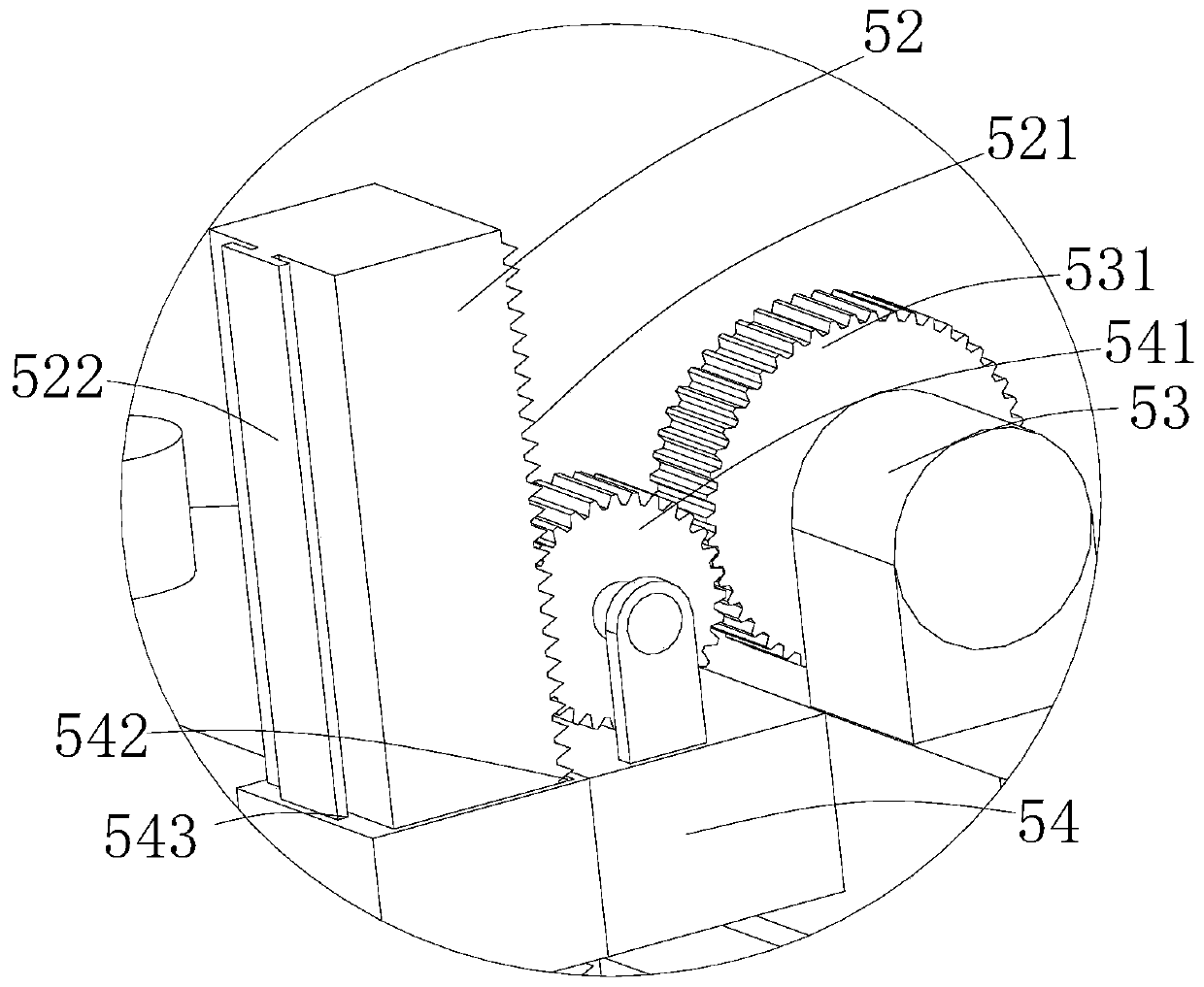

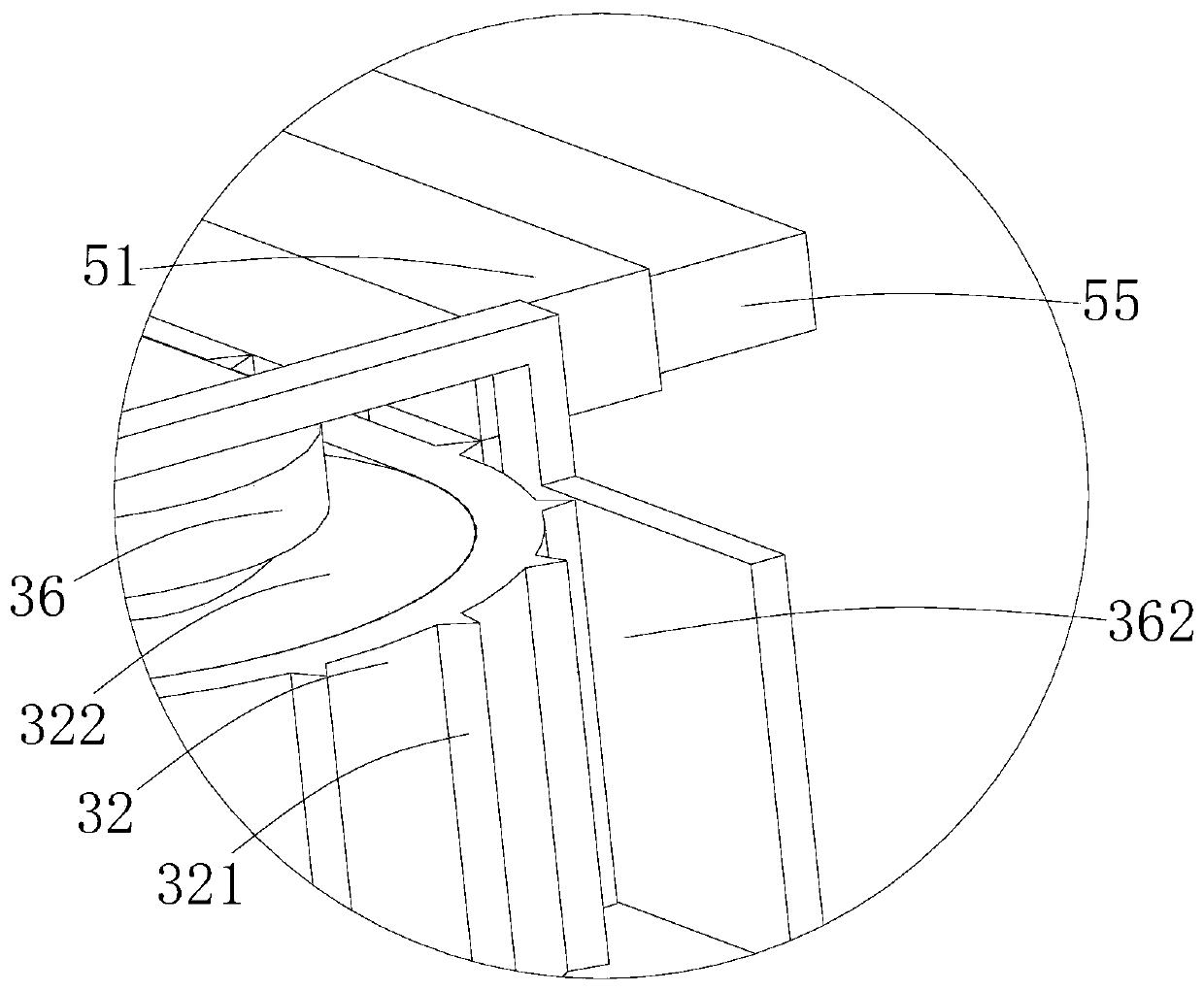

[0022] Such as Figure 1-7 As shown, a sponge crushing device for waste recycling includes a support frame 1, a plurality of cutting blades 2 for pre-cutting waste sponges, a first conveying member 11 for transporting waste sponges, and a device. Baffles 111 on both sides of the first conveying member 11, the first conveying member 11 is provided with a second conveying member 12 for conveying waste sponges, an extrusion mechanism for extruding and conveying waste sponges and for The crushing mechanism for crushing the waste sponge, through the setting of the above structure, the waste sponge can be effectively pre-cut by the cutting blade, thereby reducing the volume of the waste sponge, making the crushing of the waste sponge more labor-saving, convenient and effective The crushing efficiency of the waste sponge is improved, and at the same time, the phenomenon of waste sponge blocking the feed and discharge can be avoided, ensuring the smooth progress of the waste sponge cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com