An up-flow hydrolysis aerobic denitrification process for high ammonia nitrogen wastewater with poor biodegradability

An aerobic denitrification, up-flow technology, applied in aerobic and anaerobic process treatment, biological water/sewage treatment, special compound water treatment, etc. It can improve the system's ability to resist organic load shock, improve the ability to resist organic load shock, and improve the denitrification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

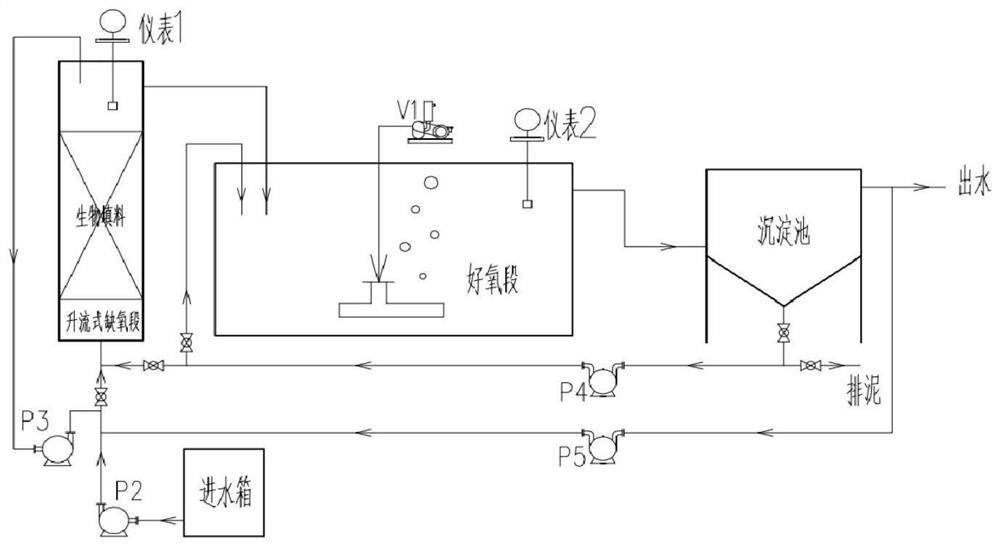

[0036]An upflow hydrolytic aerobic denitrification process for high ammonia nitrogen wastewater with poor biodegradability, including an upflow anoxic section module and an aerobic section module with built-in fillers. From bottom to top in the upflow anoxic section module, there are hydrolysis and denitrification granular sludge area, biological filler mixed flocculent sludge area and biofilm area. Entering the anoxic section module, due to the limited carbon source, partial denitrification can be realized; then the filler in the anoxic section can create a better anaerobic environment and a suitable sludge concentration, improve the hydrolysis ability of the hydrolytic acidification bacteria group, and contribute to denitrification Provide carbon source while improving the system's ability to resist the impact of organic loads and remove toxic pollutants; in the process of upflow, the formation of each area and the screening and distribution of bacterial flora are all formed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com