Method for reducing deterioration speed of rapeseed oil in frying process

A rapeseed oil and frying technology, which is applied in the production of fat oil/fat, the use of additives to preserve fat substances, and the generation of fat, etc., can solve problems such as endangering human health, improve utilization rate, facilitate food processing, and increase utilization times Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

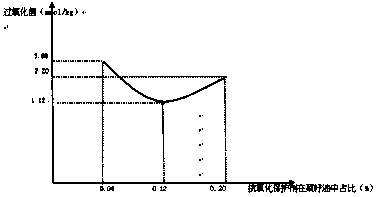

Image

Examples

Embodiment 1

[0018] A method for reducing the rate of deterioration of rapeseed oil during frying, comprising adding the prepared antioxidant protective agent to the rapeseed oil, specifically, the preparation method of the antioxidant protective agent includes the following process steps:

[0019] S1 Pick fresh wild strawberries, clean them, dry them naturally, put them in a beater with the washed fresh ginger in a mass ratio of 15:2, put 20 grams of the obtained slurry in a three-necked flask, add 50 ml of Water and ethanol, stir, and use a boiling water bath to heat up at the same time, connect the vacuum distillation device, vacuumize and heat to 55°C, the vacuum degree is 0.08MPa, discard the previous fraction, collect the product at 40°C, and carry out decolorization and deodorization obtain polyphenolic antioxidants;

[0020] S2 Weigh 80 grams of highland barley and oats in a mass ratio of 10:3, dry them in an oven at 55°C for 4 hours, send them to a crusher and crush them into powd...

Embodiment 2

[0024] A method for reducing the rate of deterioration of rapeseed oil during frying, comprising adding the prepared antioxidant protective agent to the rapeseed oil, specifically, the preparation method of the antioxidant protective agent includes the following process steps:

[0025] S1 Pick fresh wild strawberries, clean them, dry them naturally, put them in a beater with the washed fresh ginger according to the mass ratio of 16:2.5, and put 22 grams of the obtained slurry in a three-necked flask, add 55 ml of Water and ethanol, stir, and use a boiling water bath to heat up at the same time, connect the vacuum distillation device, vacuumize and heat to 58°C, the vacuum degree is 0.085MPa, discard the previous fraction, collect the product at 42°C, and carry out decolorization and deodorization obtain polyphenolic antioxidants;

[0026] S2 Weigh 85 grams of highland barley and oats according to the mass ratio of 11:3.5, dry them in an oven at 58°C for 5 hours, send them to a...

Embodiment 3

[0030] A method for reducing the rate of deterioration of rapeseed oil during frying, comprising adding the prepared antioxidant protective agent to the rapeseed oil, specifically, the preparation method of the antioxidant protective agent includes the following process steps:

[0031] S1 Pick fresh wild strawberries, clean them, dry them naturally, put them in a beater with the washed fresh ginger in a mass ratio of 18:3, put 25 grams of the obtained slurry in a three-necked flask, add 60 milliliters of Water and ethanol, stir, and use a boiling water bath to heat up at the same time, connect the vacuum distillation device, vacuumize and heat to 60°C, the vacuum degree is 0.09MPa, discard the previous fraction, collect the product at 45°C, and carry out decolorization and deodorization Get polyphenol antioxidants;

[0032] S2 Weigh 90 grams of highland barley and oats in a mass ratio of 12:4, dry them in an oven at 60°C for 6 hours, send them to a crusher and crush them into ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com