Device and method for testing sealing performance of natural gas hydraulic drive pipeline of diesel engine

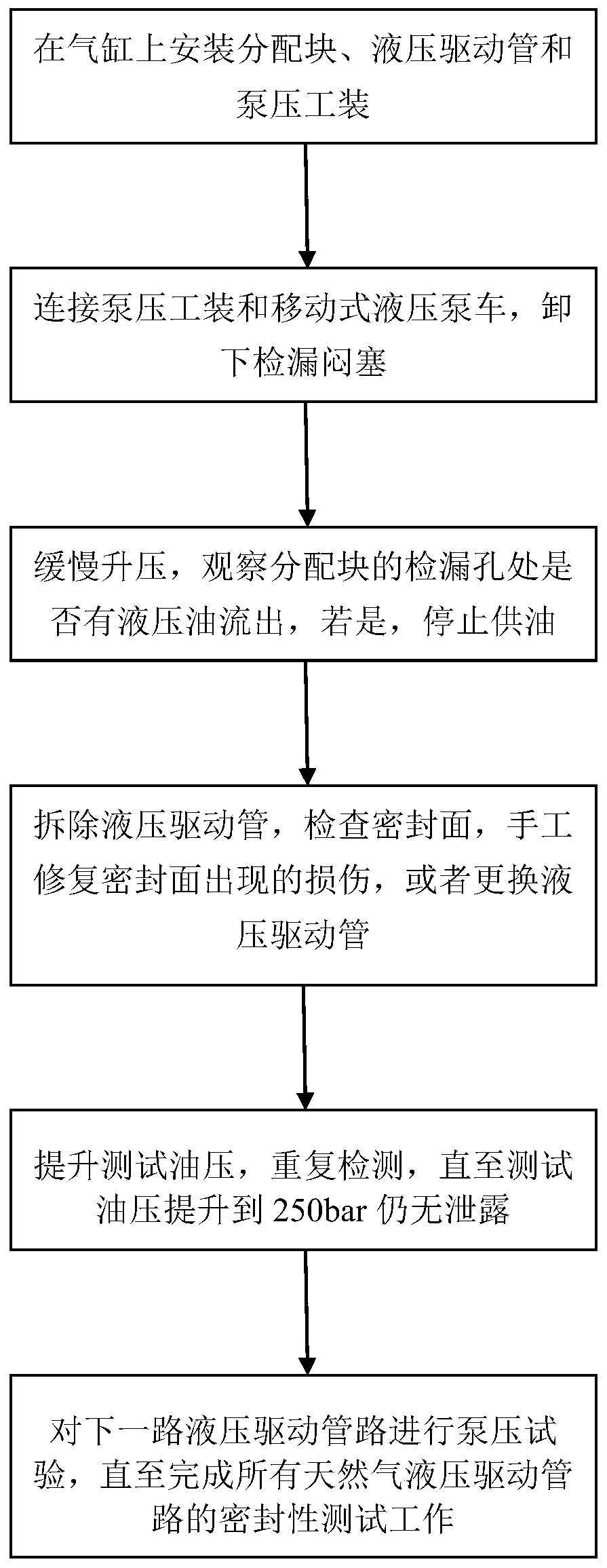

A test method and drive tube technology, applied in fluid tightness test, machine/structural component test, measuring device, etc., can solve problems such as narrow bench space, long time occupied by bench, inconvenient operation, etc., to avoid Safety hazards, shortened occupancy cycle, effects of quick connection and disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

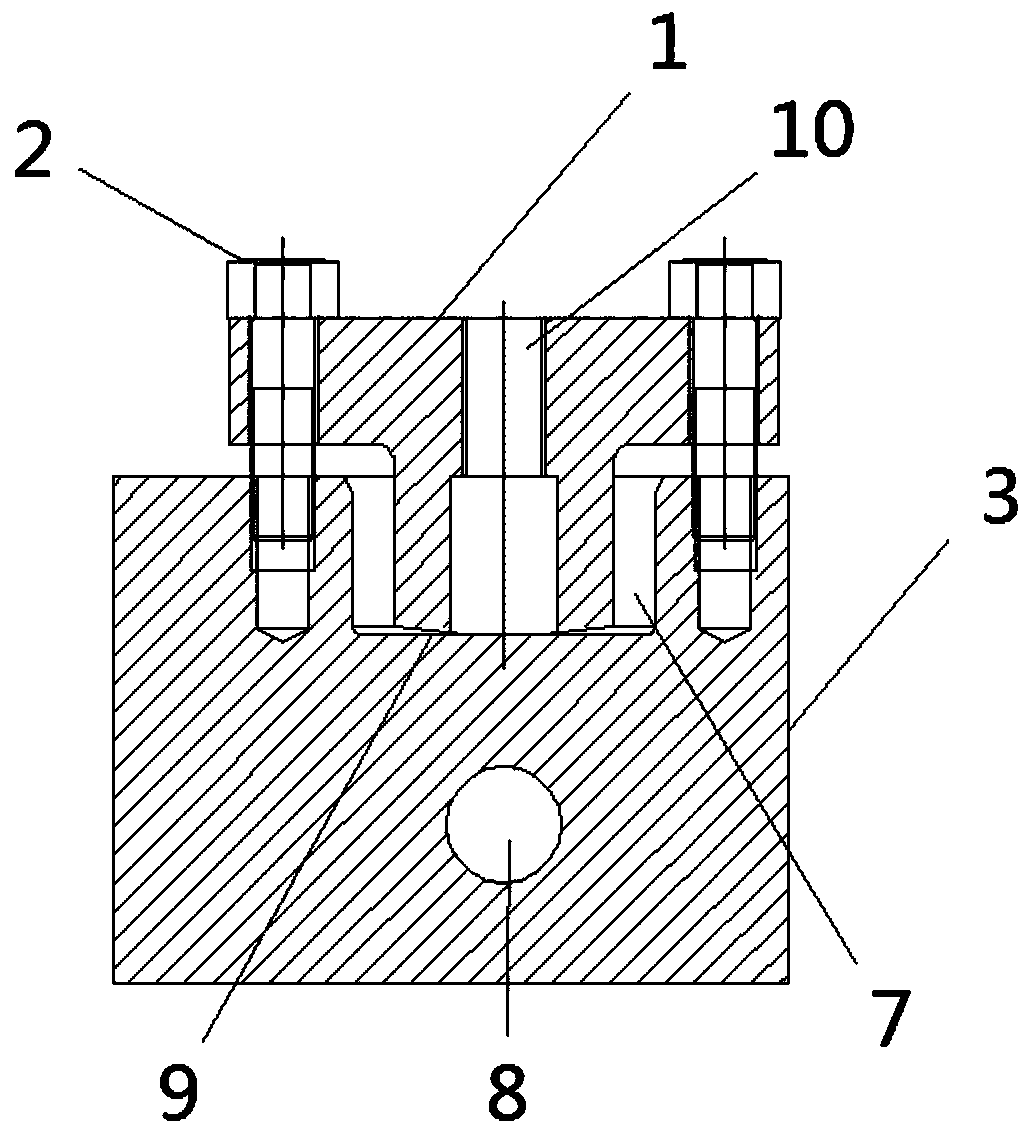

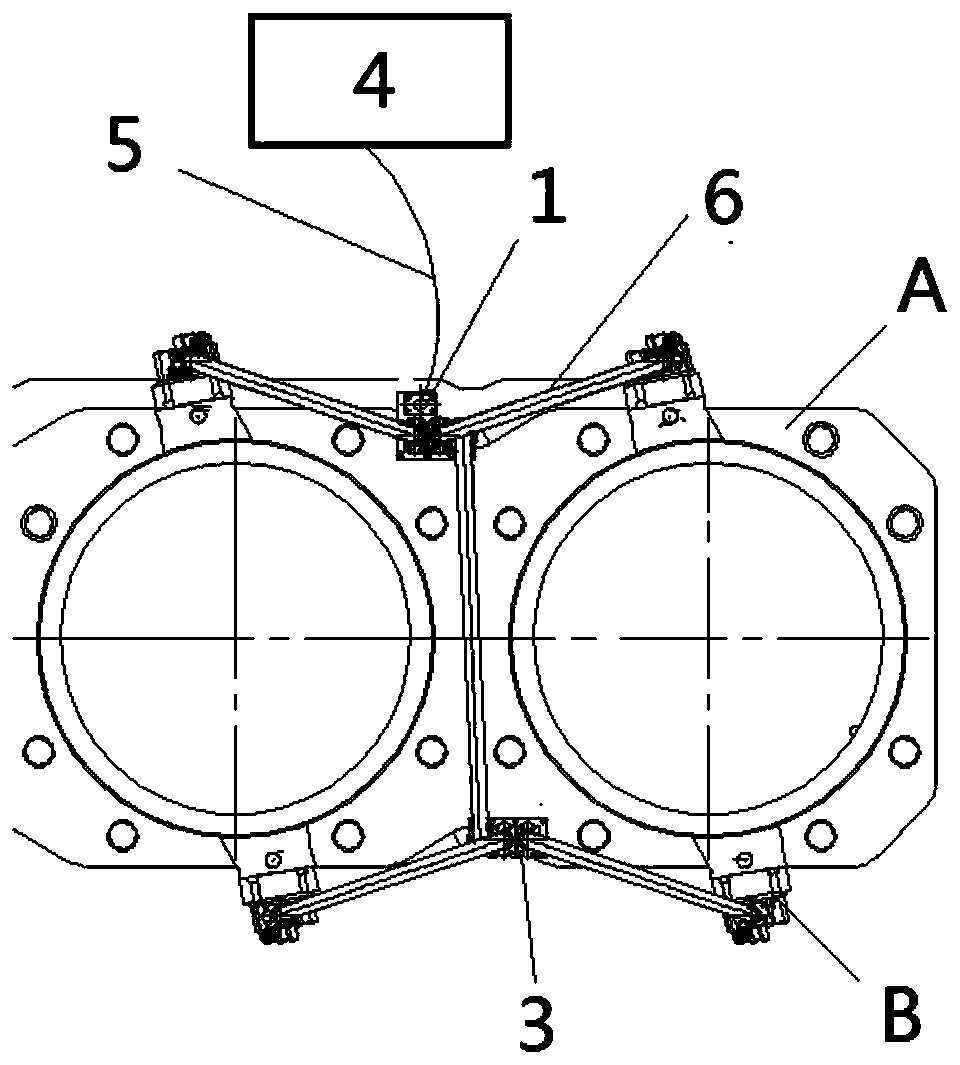

[0029] see figure 1 , the pumping tool 1 is provided with a hydraulic oil passage, which communicates with the upper surface of the pumping tooling 1 through the quick interface 10 , and the lower surface of the pumping tooling 1 is a sealing spherical surface 9 . The pumping tooling 1 is fixedly connected to the distribution block 3 of the gas hydraulic drive pipeline through the connecting bolt 2, and is in close contact with the distribution block 3 by means of the sealing spherical surface 9. The spherical surface size of the sealing spherical surface 9 is determined according to the The allocation block 3 is determined and processed. The distribution block 3 is provided with a leak detection hole, a hydraulic oil inlet 7 and a plurality of hydraulic oil outlets 8, the hydraulic oil inlet 7 is connected to the hydraulic oil outlets 8, and the leak detection hole is connected with a leak detection plug. see figure 2 , the distribution block 3 is installed on the cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com