Self-sensing FRP rib embedded with piezoelectric ceramic sensor and using method thereof

A technology of piezoelectric ceramics and piezoelectric ceramic sheets, which is applied in the direction of analyzing solids by using sound waves/ultrasonic waves/infrasonic waves, testing the strength of materials by applying stable tension/pressure, and conducting material analysis by using sound waves/ultrasonic waves/infrasonic waves to achieve structural design. novel effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be described below in combination with specific embodiments.

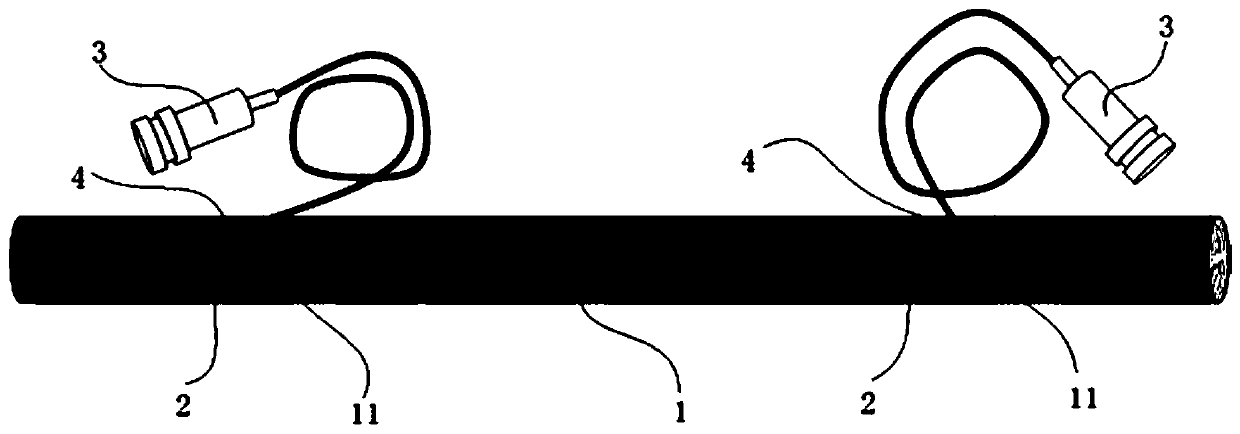

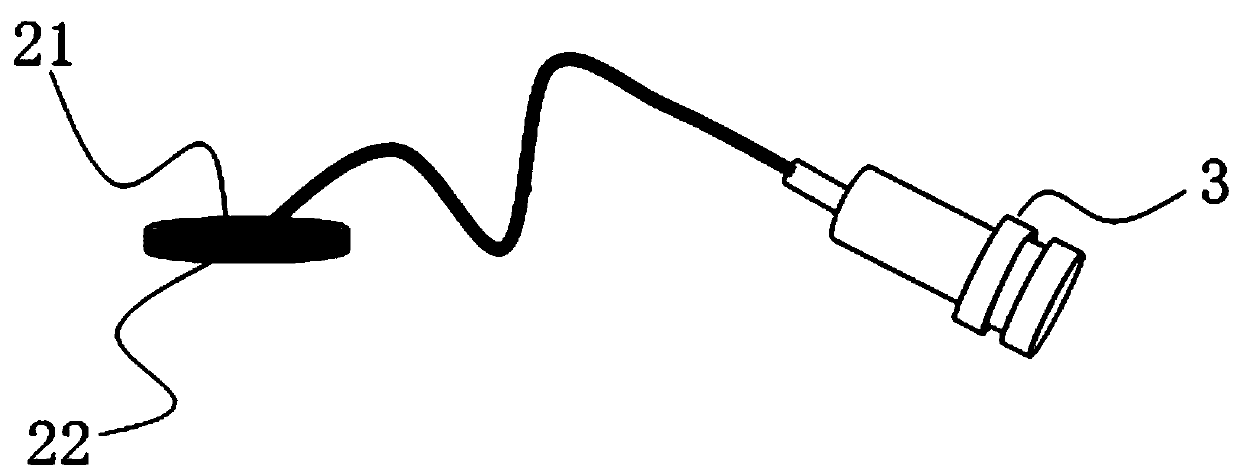

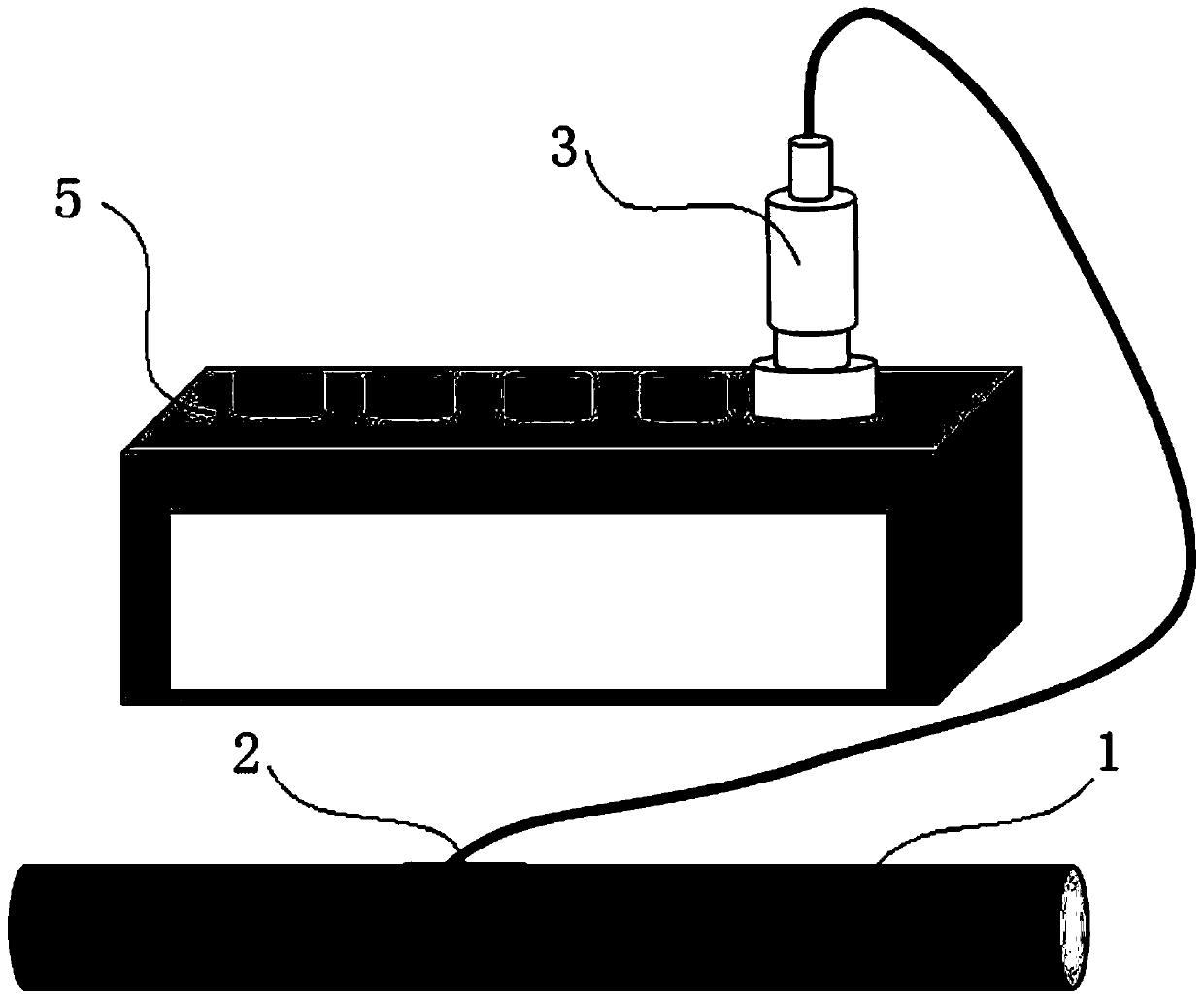

[0050] Such as figure 1 with image 3 As shown, a self-sensing FRP bar embedded with a piezoelectric ceramic sensor includes a FRP bar 1 and a sensor assembly. The sensor assembly includes a piezoelectric ceramic sensor 2 and a BNC connector 3. The piezoelectric ceramic sensor 2 includes a piezoelectric ceramic sheet 21 and the copper shell 22 wrapped on the periphery of the piezoelectric ceramic sheet 21, the positive terminal of the piezoelectric ceramic sheet 21 is connected with a positive lead, the negative terminal of the piezoelectric ceramic sheet 21 is connected with a negative lead, the positive lead and the negative lead are respectively Pass through the copper shell 22 and lead out from the upper surface of the copper shell 22 respectively, and the positive lead and the negative lead are respectively wrapped by the insulating outer cladding; the positive terminal of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness value | aaaaa | aaaaa |

| Thickness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com