Shipborne online flue gas monitoring device installed in marine engine room

A monitoring instrument and flue gas technology, which is applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of ineffective protection of flue gas sensors, inability to control spraying operations freely, etc., and achieve good effect of flue gas elimination operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

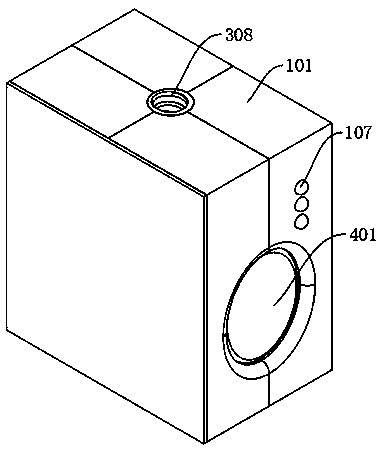

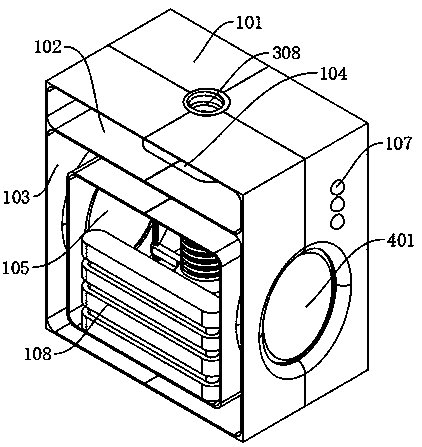

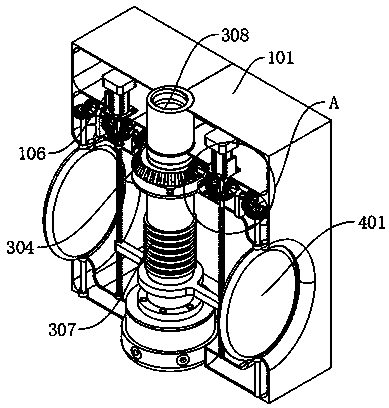

[0027] A ship-borne flue gas online monitor installed in the engine room of a ship, comprising: a main body casing 101, a power bin 102, a starting bin 103, a waterproof bin 104 and a monitoring bin 105, and the inside of the main body casing 101 is sequentially provided with power bins from top to bottom 102. Starting compartment 103 and monitoring compartment 105. The middle part of the starting compartment 103 is provided with a waterproof compartment 104. The left and right sides of the power compartment 102 are fixed with servo motors 106. The lower end of the main shaft of the servo motor 106 is fixedly connected with the starting mechanism, and the upper end of the starting mechanism is inward. One side is meshed and connected with the starting valve mechanism, the upper end of the starting mechanism is meshed and connected with the monitoring starting mechanism, the lower side of the starting mechanism is fixedly connected with the spraying mechanism, and the smoke monit...

Embodiment 2

[0029] Embodiment 2: Based on Embodiment 1, the difference is:

[0030]The starting mechanism includes: a rotating gear 201, a rotating screw mandrel 202, a moving block 203 and a moving ring 204, the lower end of the main shaft of the servo motor 106 is fixedly connected with the upper end of the rotating screw mandrel 202, and the upper end of the rotating screw mandrel 202 is fixedly connected with the axis center of the rotating gear 201. The screw rod 202 is threaded with a moving block 203, the inner side of the moving block 203 is fixedly connected to the left and right ends of the moving ring 204, the moving ring 204 is fixedly connected to the upper end of the spraying mechanism, and the inner side of the rotating gear 201 is connected to the start valve mechanism. Mesh connection, the outer side of the rotating gear 201 is meshed with the monitoring and starting mechanism.

[0031] The monitoring and starting mechanism includes: a rotating sealing plate 401, a rotati...

Embodiment 3

[0034] Embodiment 3: Based on Embodiment 1 and 2, but the difference is:

[0035] The starting valve mechanism includes: external transmission gear 301, internal transmission gear 302, transmission shaft 303, rotating gear ring 304, moving rod 305, sealing plate 306, connecting hose 307 and external connecting pipe 308, the inner side of rotating gear 201 and The lower side of the external transmission gear 301 is meshed and connected, the axis of the external transmission gear 301 is fixedly connected with the outer end of the transmission shaft 303, the middle part of the transmission shaft 301 is movably connected with the inner wall of the waterproof chamber 104, and the inner end of the transmission shaft 301 is connected with the axis of the internal transmission gear 302 Fixedly connected, the lower side of the internal transmission gear 302 meshes with the left and right sides of the rotating gear ring 304, and the upper and lower sides of the rotating gear ring 304 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com