Electrochromic automobile glass with electric heating and electromagnetic shielding functions

An electrochromic and electromagnetic shielding technology, applied in nonlinear optics, instruments, optics, etc., can solve problems such as poor conductivity, discoloration failure, poor low temperature performance, etc., achieve reasonable thickness design, increase discoloration rate, and enrich applications range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described in detail below in conjunction with the accompanying drawings.

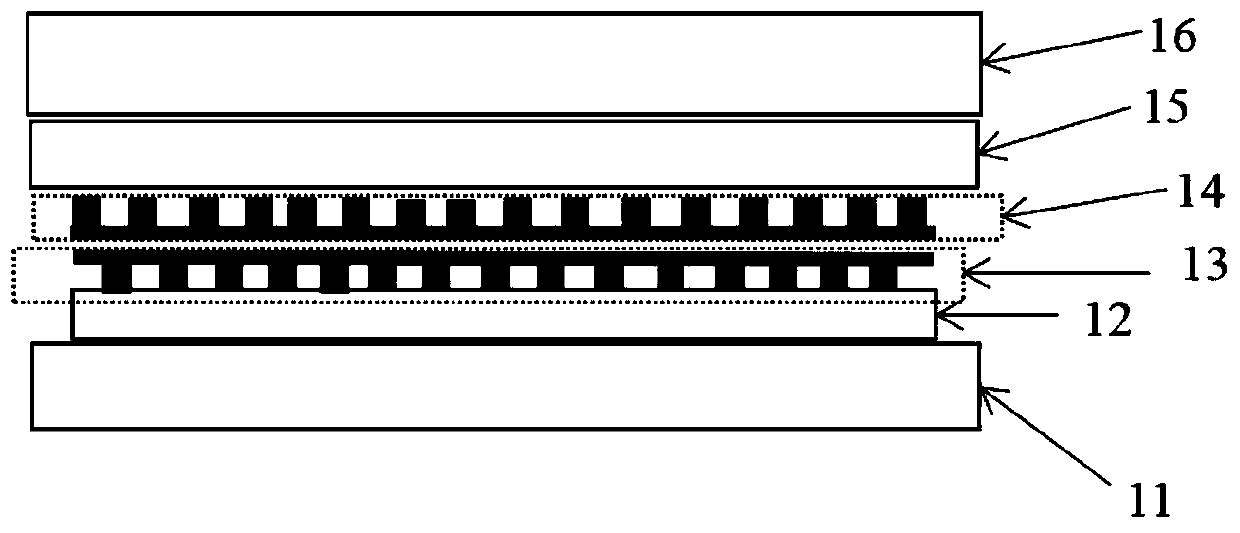

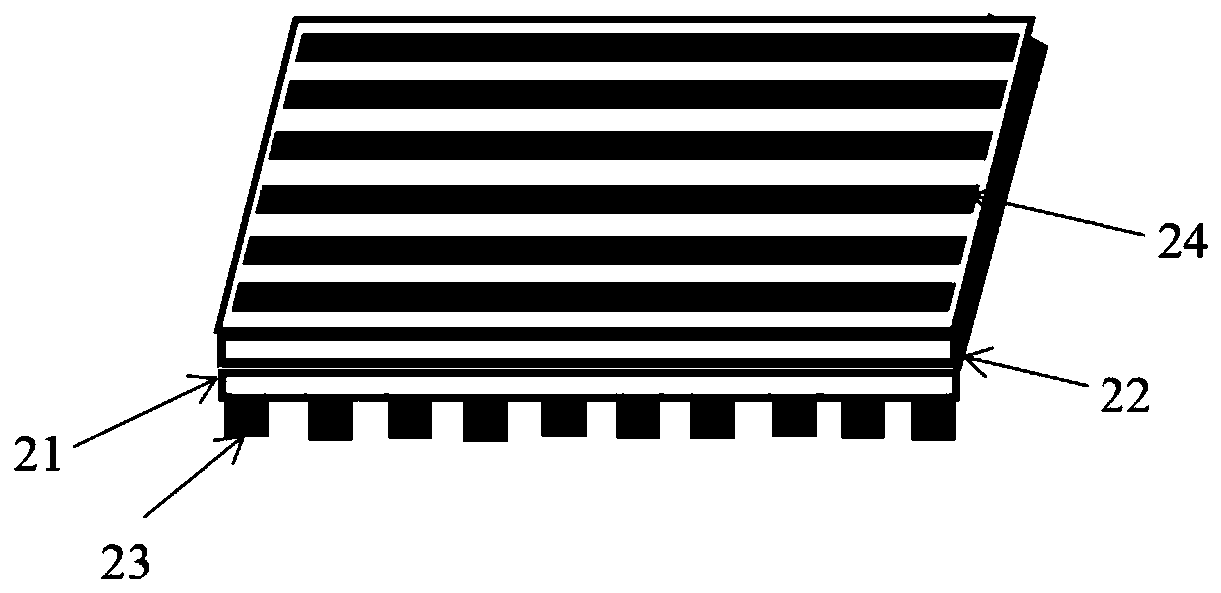

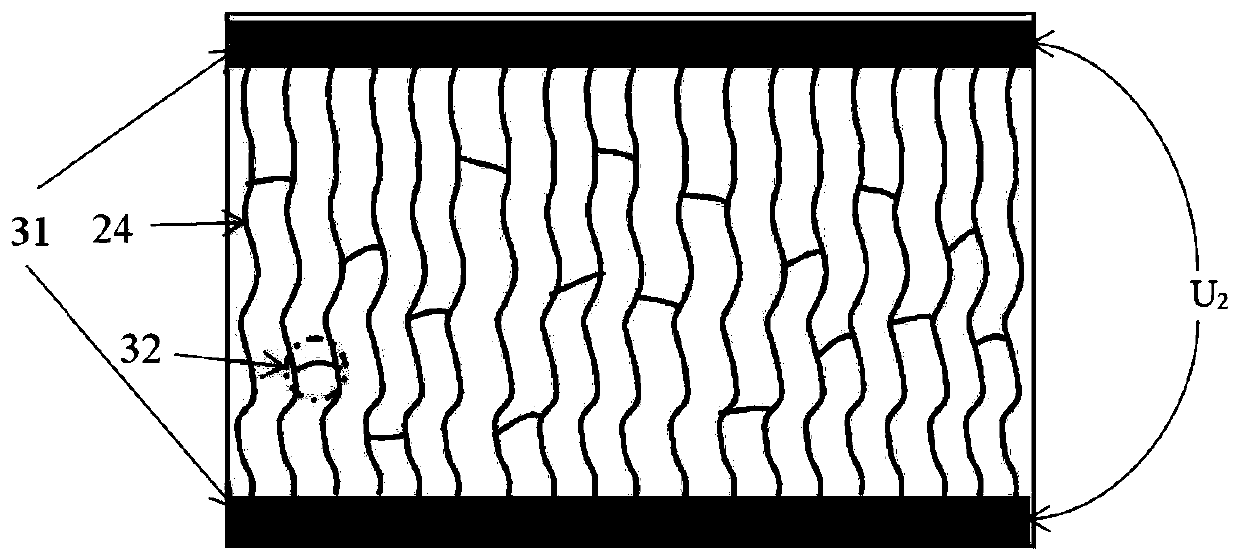

[0032] like figure 1 , figure 2 As shown, the present invention has an electrochromic automotive glass with electric heating and electromagnetic shielding, in which a first glass layer 11, an electrochromic module 12, a first mesh layer 13, and a second mesh layer are sequentially stacked along the thickness direction. 14. Adhesive layer 15, second glass layer 16. like figure 2 As shown, the first grid layer 13 includes a first transparent substrate 21 and a first metal wire 23, the second grid layer 14 includes a second transparent base 22 and a second metal wire 24, and the first metal wire 23 is arranged at the second A transparent substrate 21 faces the side of the electrochromic module 12 , and the second metal wire 24 is arranged on the side of the second transparent substrate 22 facing the second glass layer 16 . Laminate the first mesh layer 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com