Operation method of intelligent control and monitoring system for machining process

A technology of intelligent control and monitoring system, applied in general control system, control/regulation system, program control and other directions, can solve the problem of not being able to achieve intelligent response, and achieve the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

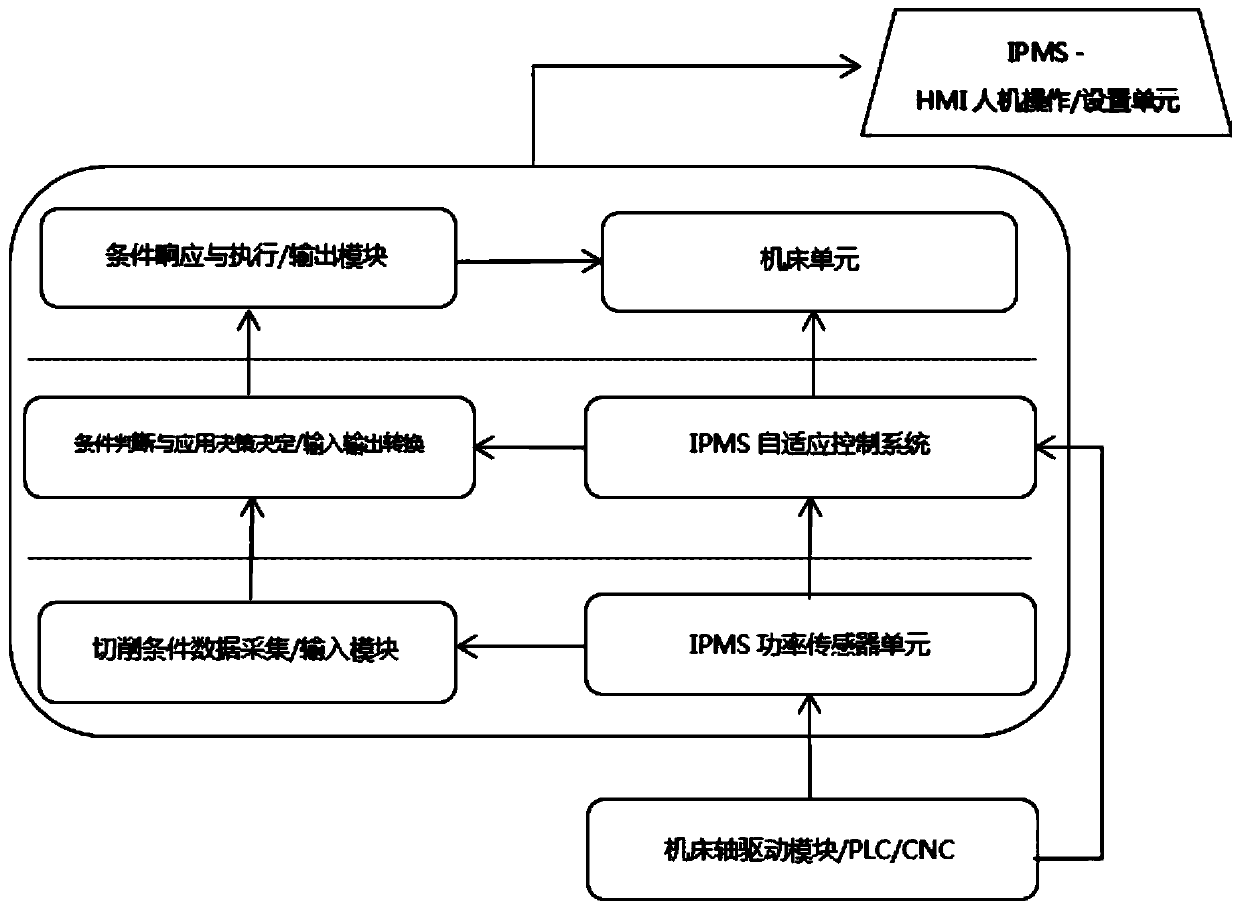

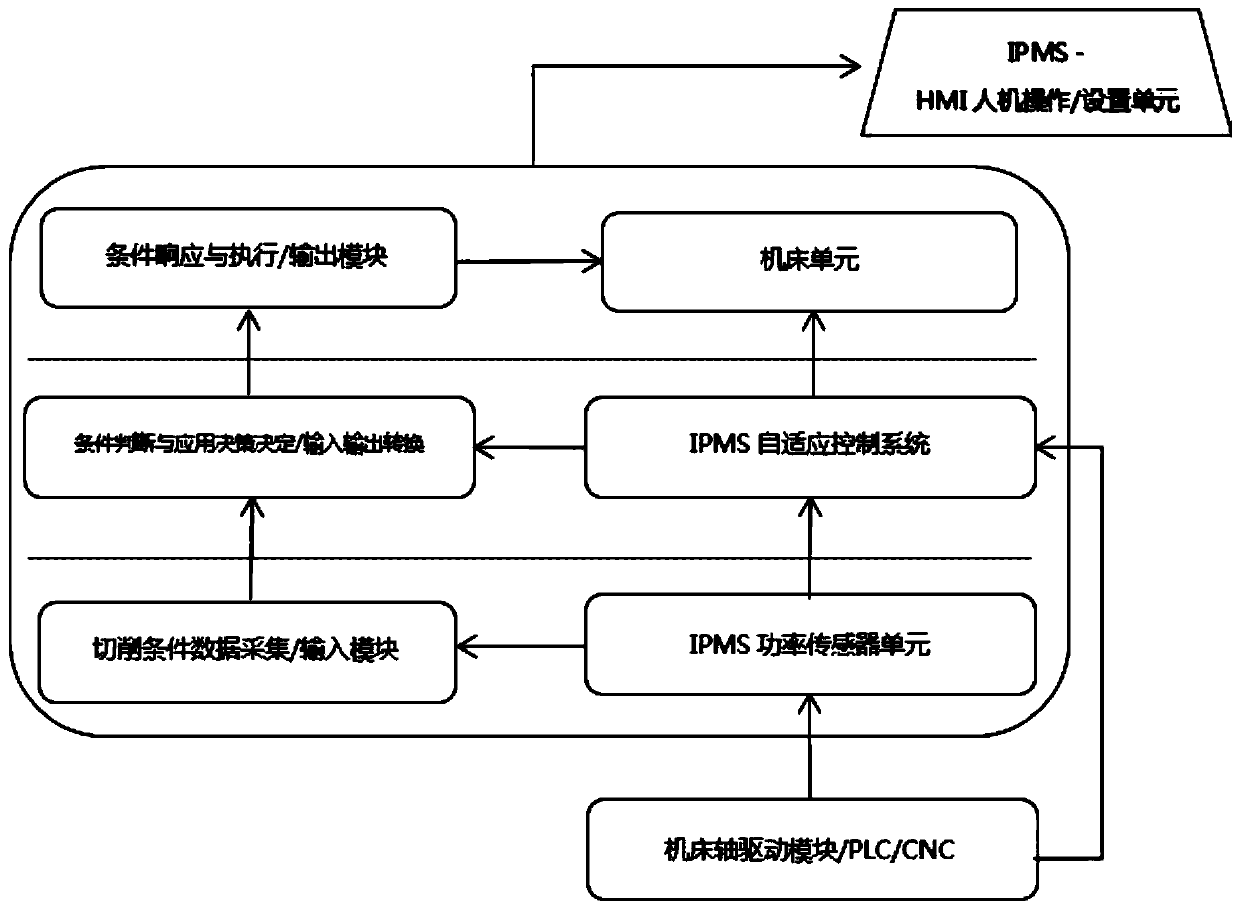

[0053] An operation method of an intelligent control and monitoring system for processing, such as figure 1 As shown, it is achieved through the following steps:

[0054] Set the system to the learning mode, perform tool processing normally, and collect the power value at each instant;

[0055] Switch the system to the operating mode, and obtain the current state data of the device through various sensors;

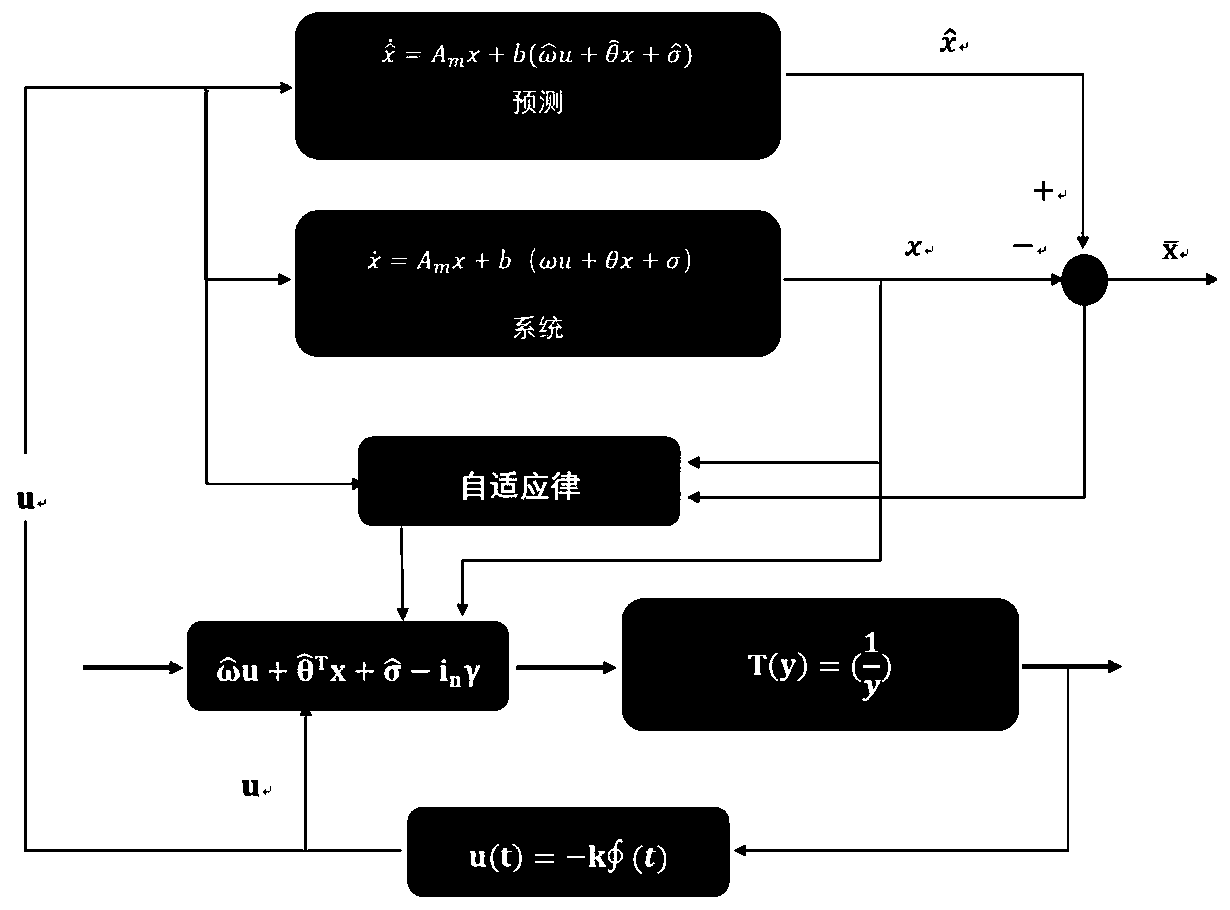

[0056] Through the state predictor, predict the next state of the equipment, and compare the predicted state with the actual collected state;

[0057] According to the comparison results, it can automatically adjust various data in the state prediction period, and continuously and automatically adjust the feed rate and power of the equipment to protect the tools and improve the processing efficiency.

[0058] In some embodiments of the present invention, the intelligent control and monitoring system includes a machine tool axis drive module, a power sensor module, an adaptive contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com