Waterproof plugging process for cable hole

A technology for waterproof plugging and cables, which is applied to electrical components, pipes, pipes/pipe joints/fittings, etc., and can solve the problems of decreased water resistance, decreased water blocking effect, and easy aging of asphalt.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

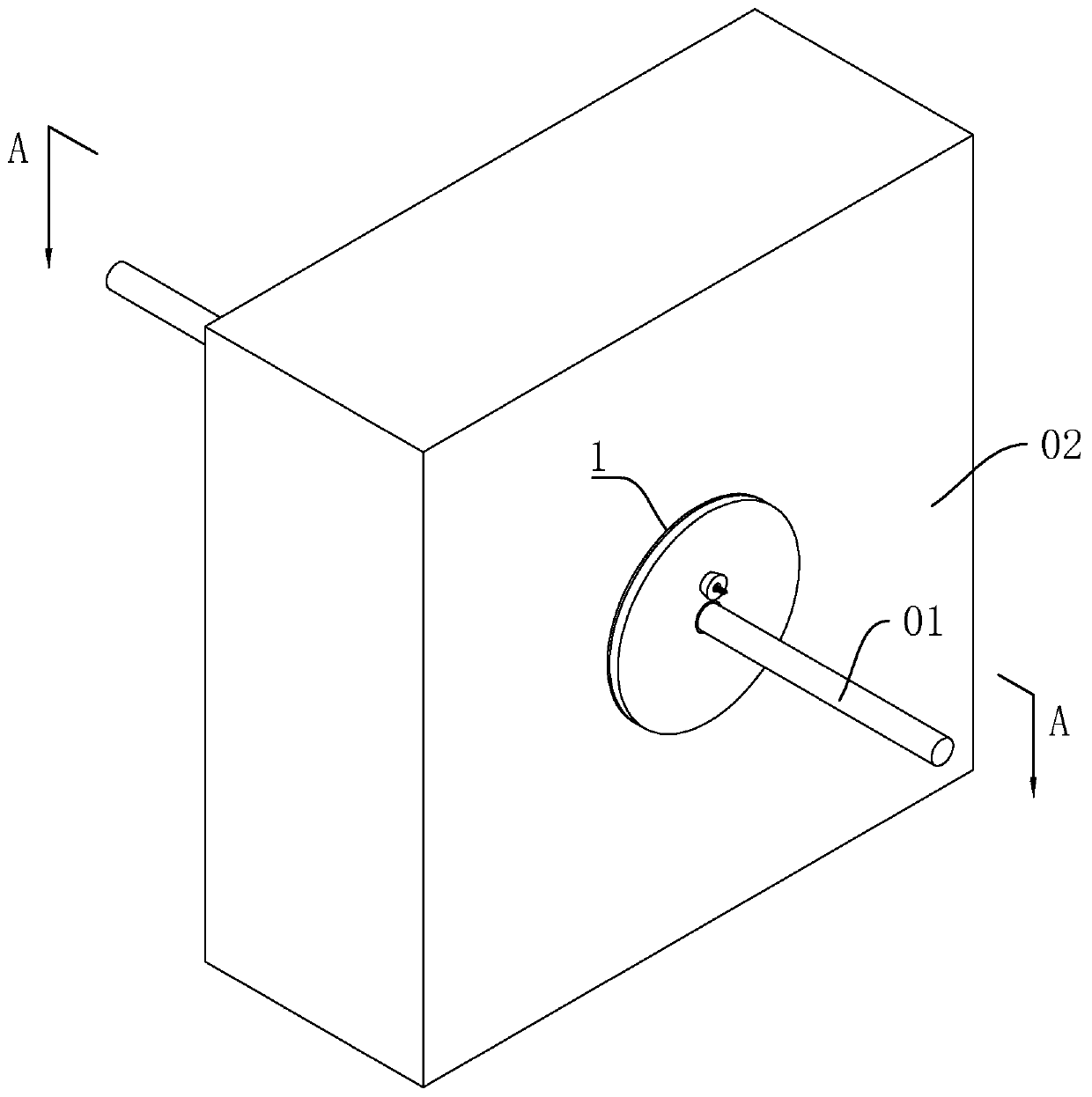

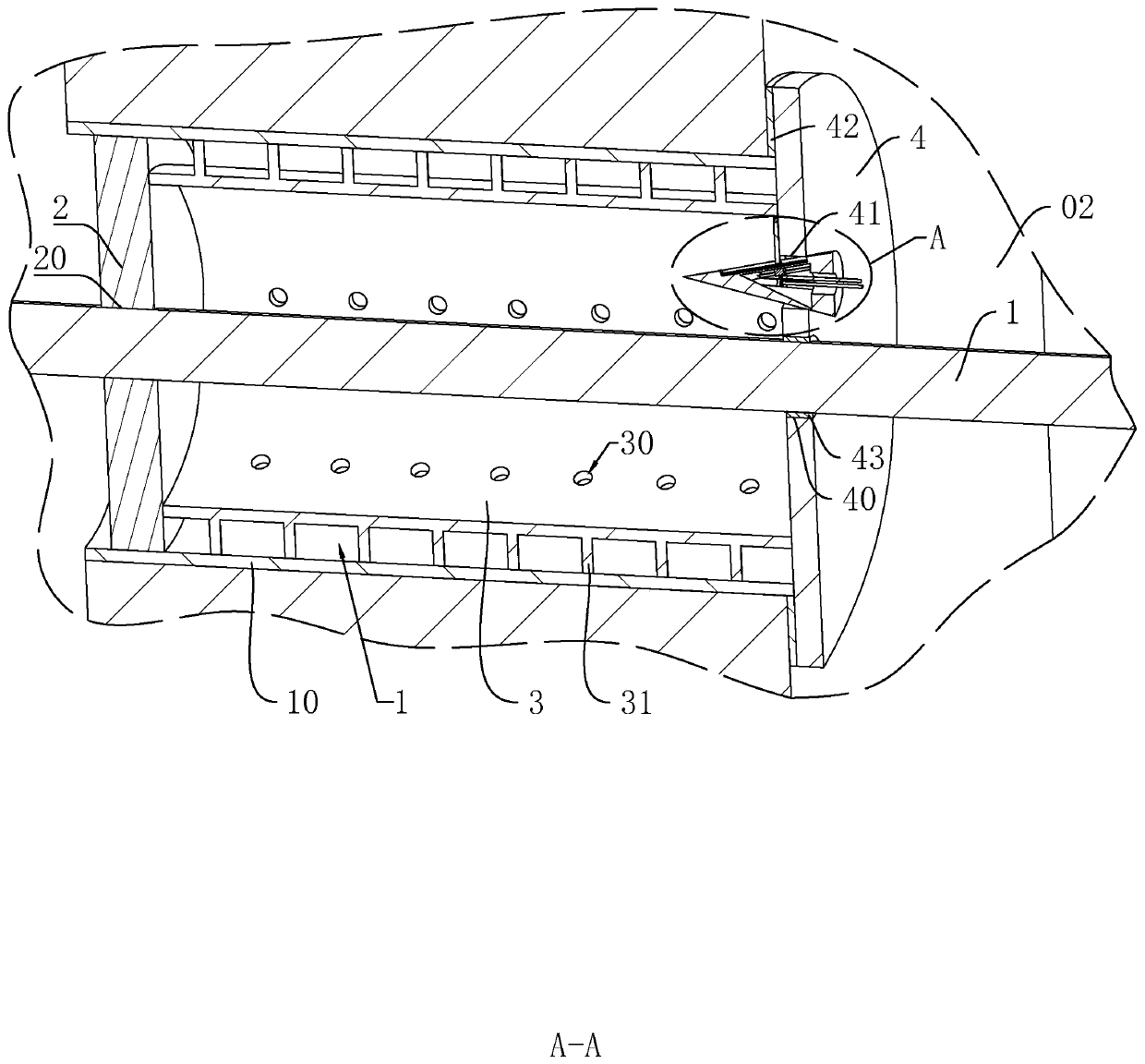

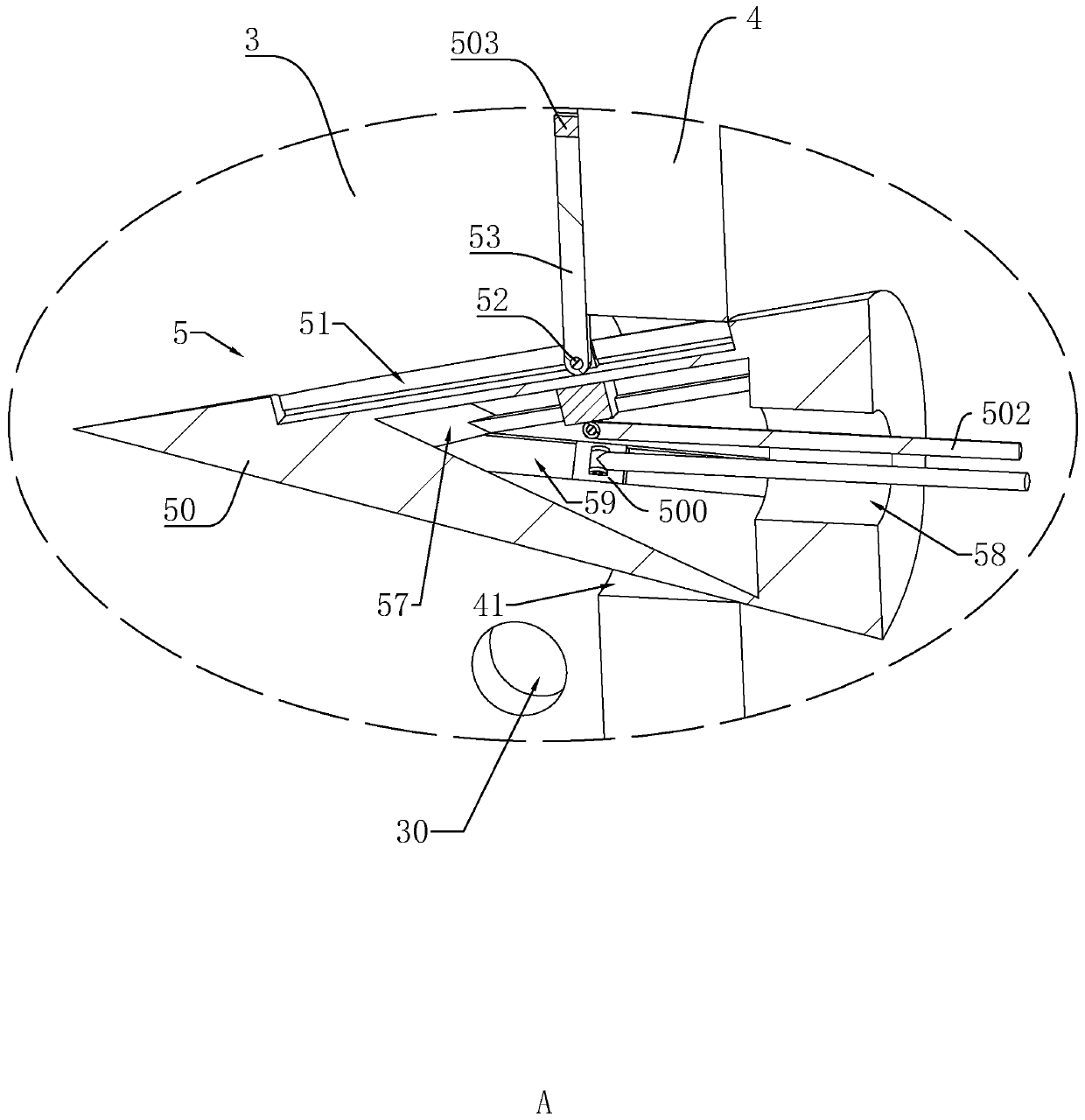

[0045] refer to figure 1 and figure 2 , a cable hole waterproof plugging process, the specific steps are as follows: S1, the inner wall of the cable hole 1 is polished to smooth, and on the inner wall of the cable hole 1, the water-swellable water-stop glue is used to adhere the water-swelling Expandable rubber waterstop 10, preferably a water-swellable rubber waterstop 10 with water-stop ribs on both sides, when filled with filler, when the moisture in the filler meets the water-swellable rubber waterstop 10, it will pass through the water-swellable rubber waterstop 10 The water-swellable performance of the expansive rubber waterstop 10 causes swelling, and then the gap between the filler and the water-swellable rubber waterstop 10 can be filled to reduce the gap between the two, thereby reducing the flow of water from Infiltration between the filler and the water-swellable rubber waterstop 10; when water infiltrates between the cable hole 1 and the water-swellable rubber w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com